Multi-medium multi-channel discrete low-NOx pulverized coal burner for rotary cement kiln

A pulverized coal burner and cement rotary kiln technology, which is applied in the direction of burners, lighting and heating equipment, etc., can solve the problem that NOx is difficult to meet environmental protection requirements, and achieve the requirements of reducing NOx generation, less primary air volume, and low NOx emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

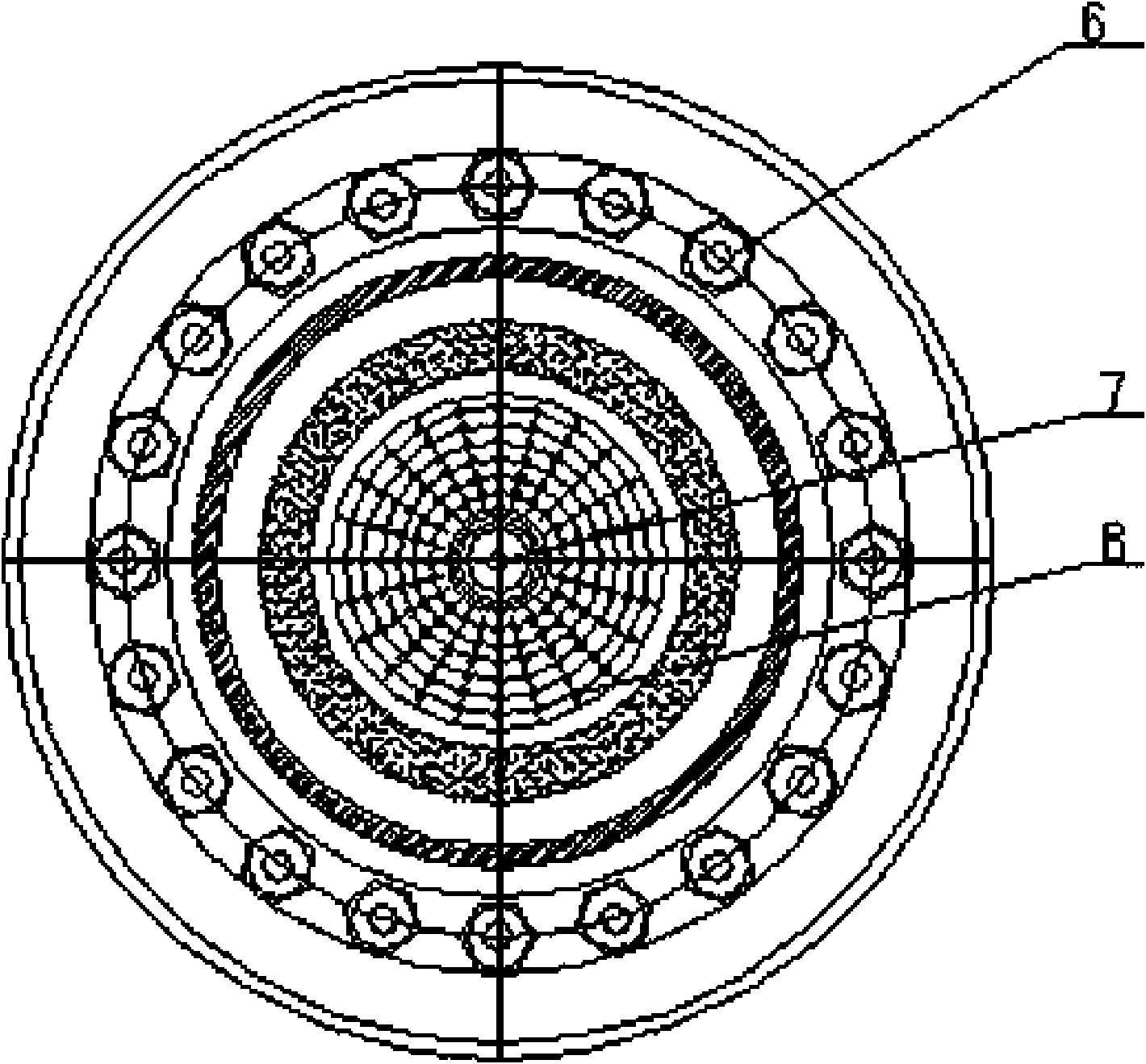

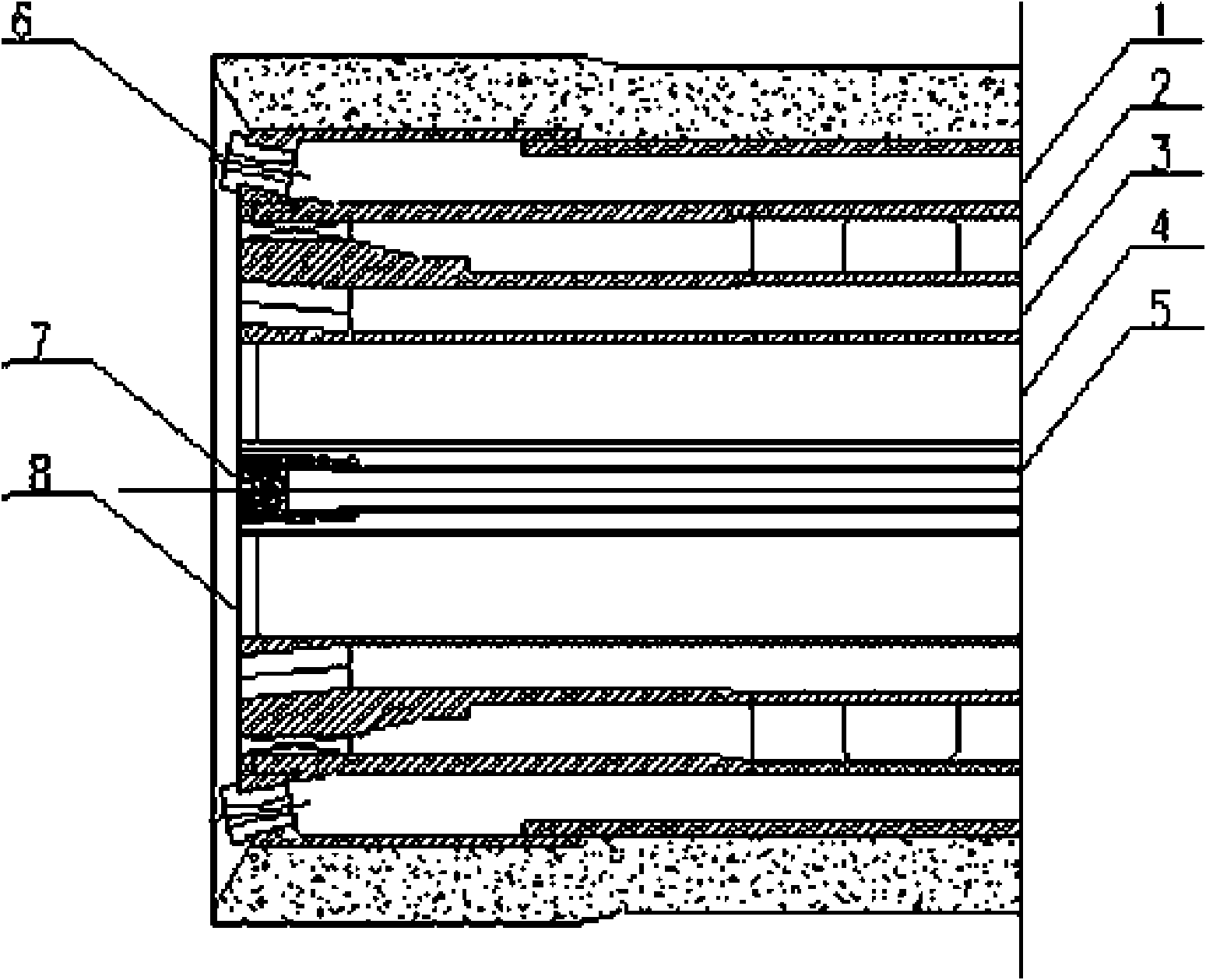

[0017] figure 1 , 2 Middle, 1-axial air duct; 2-swirling air duct; 3-coal air duct; 4-central air duct; 5-coal water slurry pipeline; 6-Rafal tube supersonic nozzle; 7-coal water slurry nozzle ;8-central wind distribution board

[0018] The cement rotary kiln low NOx pulverized coal burner is a multi-media multi-channel pulverized coal burner, which is composed of four concentric annular channels, which are axial flow air channel 1, swirl air channel 2, coal air channel 3 and A central wind passage 4, a coal water slurry pipeline 5 is set in the center, and a coal water slurry burner 7 is set at the outlet of the coal water slurry pipeline 5 . An air distribution plate 8 having 10 air outlet holes (circular holes) is arranged at the outlet of the central air passage.

[0019] The outermost axial-flow air duct has 10 to 40 Lafal tube supersonic nozzles 6 evenly distributed in the circumferential direction at its air outlet, which are discretely arranged at a certain angle wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com