Self-heating heat responsive element and liquid level detector assembled thereby

A technology of liquid level detector and thermal element, applied in the direction of liquid level indicator for physical variable measurement, etc., can solve the problems of small working current, short response time, slow response, etc., and achieve small external interference and strong anti-interference. Ability, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

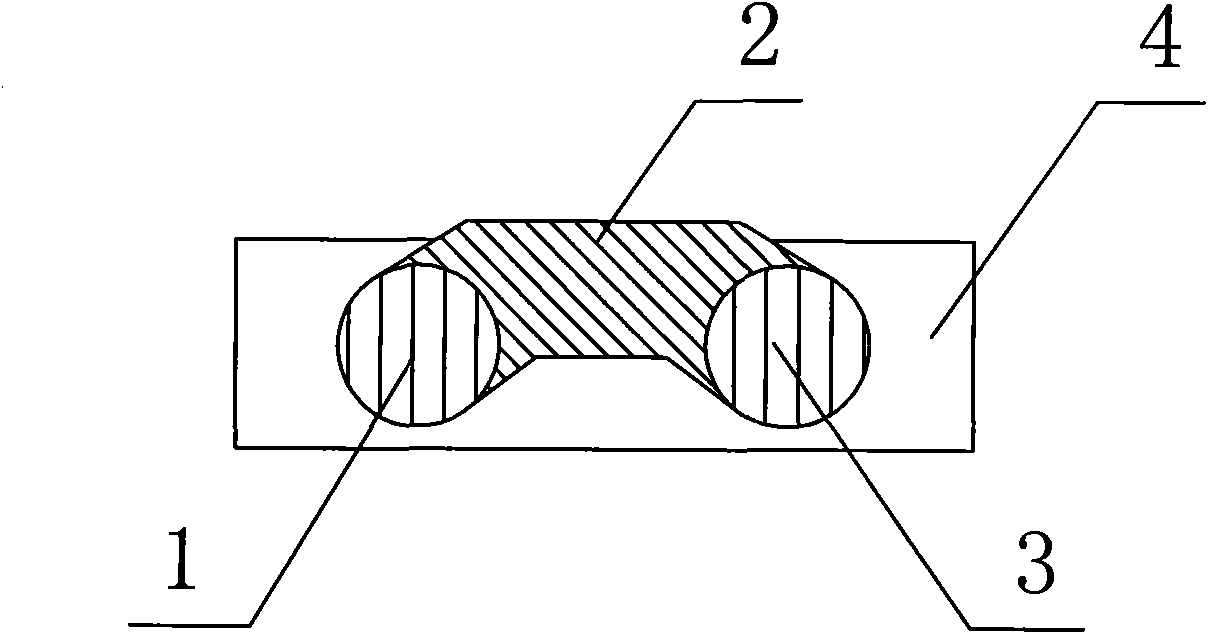

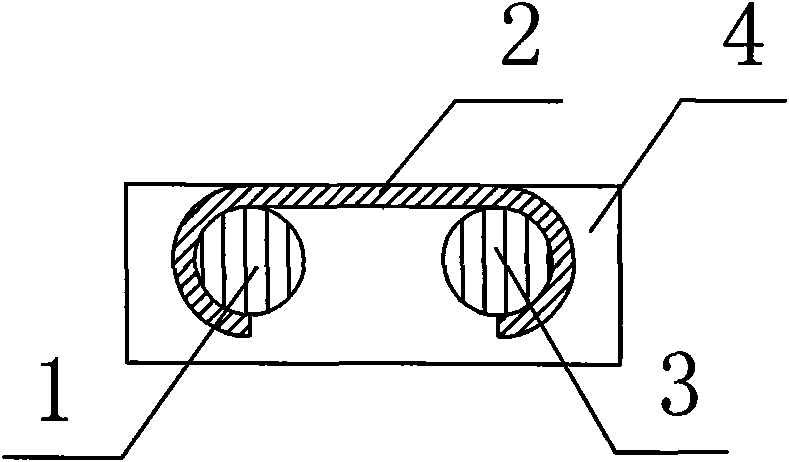

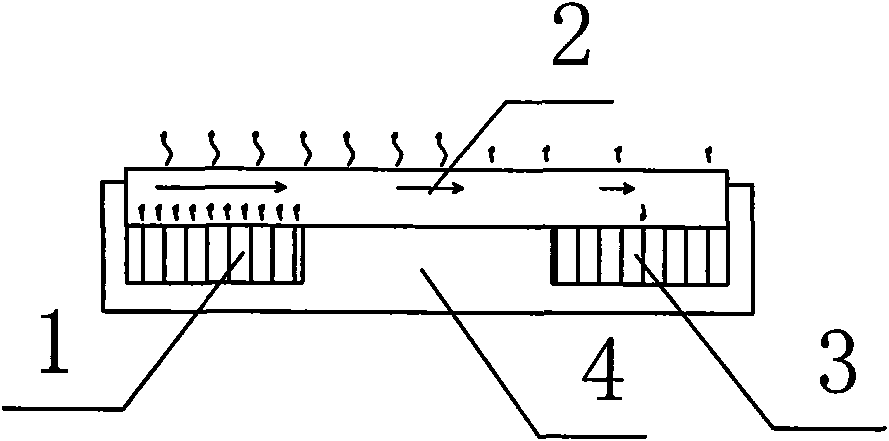

[0050] Such as figure 1 Shown: a self-heating thermosensitive element, the key of which is: composed of a heating resistor 1, a heat conducting medium 2, and a thermosensitive element 3, the heat conducting medium 2 is connected to the heating resistor 1 and the thermosensitive element 3, and the heat conducting medium 2 is connected with The heating resistor 1 is in close contact with the heat-sensitive element 3, and the heat-conducting medium 2 is exposed to the working environment. The heat conduction medium 2 is in close contact with the working environment medium, which can realize sufficient heat exchange.

[0051] The heat conducting medium 2 is located between the heating resistor 1 and the heat sensitive element 3 .

[0052] Its working principle is: when the self-heating thermal element is in the air, the heat emitted by the heating resistor 1 is transferred through the heat-conducting medium 2, a small part is dissipated into the air, and most of it reaches the th...

Embodiment 5

[0063] Such as Figure 5 Shown: in order to fully express the application of self-heating thermal element, the present invention describes a kind of liquid level detector, and its key is: by reference self-heating thermal element K, output circuit, a group of self-heating thermal element 61 ~6i, a set of voltage comparators 71~7i and a set of voltage resistors;

[0064] Wherein the heating resistor 1 in the first self-heating thermistor 61 is connected between the positive and negative poles of the power supply, and the thermistor 3 in the first self-heating thermistor 61 is connected in series with the first voltage dividing resistor R11 and then connected to the positive and negative poles of the power supply. Between the negative poles, the common terminal of the thermistor 3 and the first voltage dividing resistor R11 is connected to the positive or negative input terminal of the first voltage comparator 71;

[0065] The connection relationship between the self-heating th...

Embodiment 6

[0072] Embodiment 6, the working principle of this embodiment is the same as that of Embodiment 5, the difference is that:

[0073] Such as Figure 6 As shown: the output terminals of the voltage comparators 71-7i group are connected with a V / I conversion circuit, and the V / I conversion circuit is composed of a V / I converter 10, a pull-down resistor R3 and a group of series resistors R31-R3 (i-1) composition;

[0074] Wherein the first series resistor R31 is connected between the output terminals of the first voltage comparator 71 and the second voltage comparator 72, and the second series resistor R32 is connected between the second voltage comparator 72 and the third voltage comparator Between the output terminals of 73;

[0075] The other series resistors R33~R3 (i-2) The connection relationship with other voltage comparators 73~7i groups is consistent with the connection relationship of the first and second series resistors R31, R32, the first, second and third voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com