Device for automatically testing optical waveguide devices in batches

An automatic test device and optical waveguide technology, applied in the direction of testing optical performance, etc., can solve the problems of poor comparability, unstable data, time-consuming and labor-intensive, etc., to meet the test requirements, improve measurement efficiency, and ensure consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

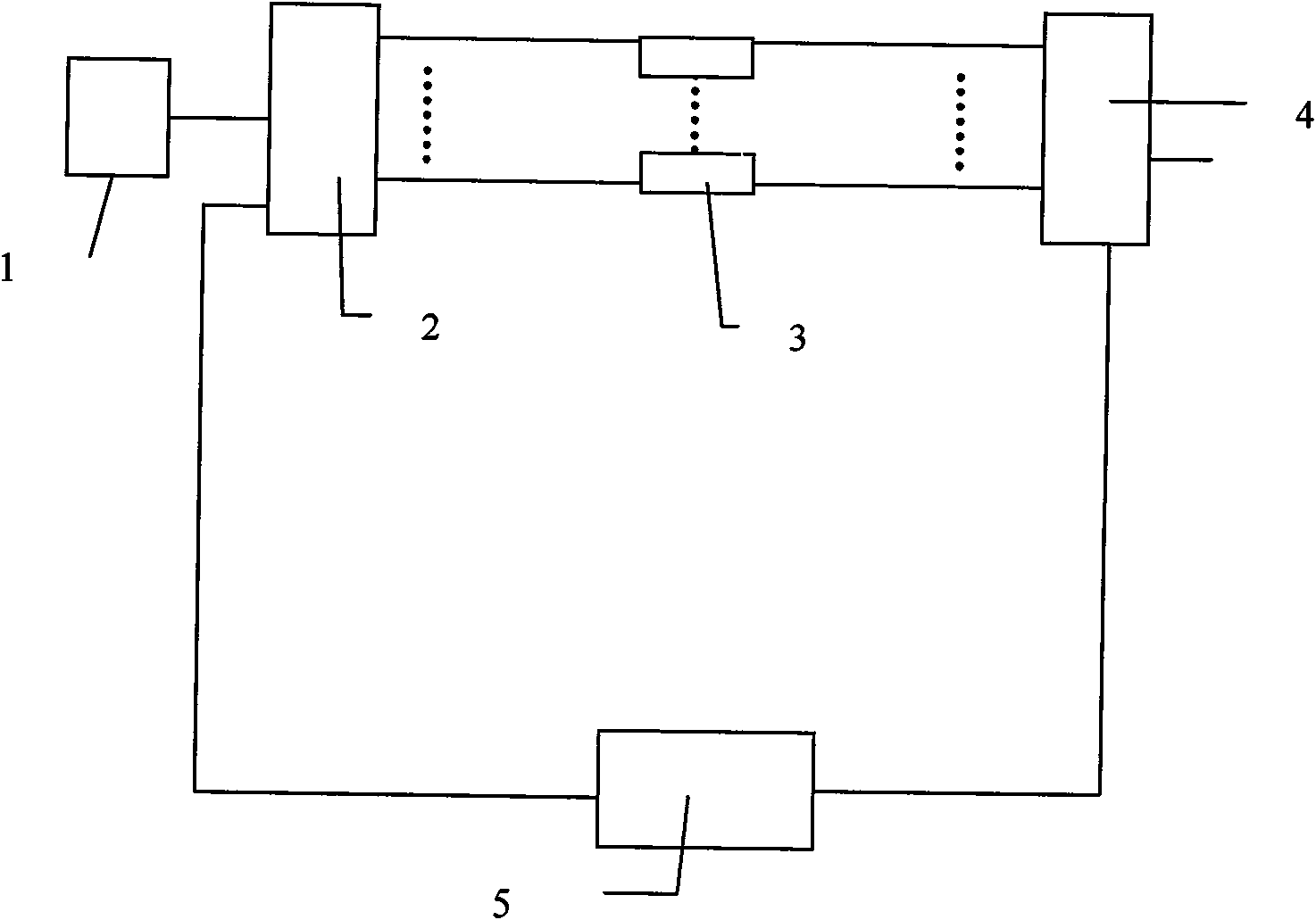

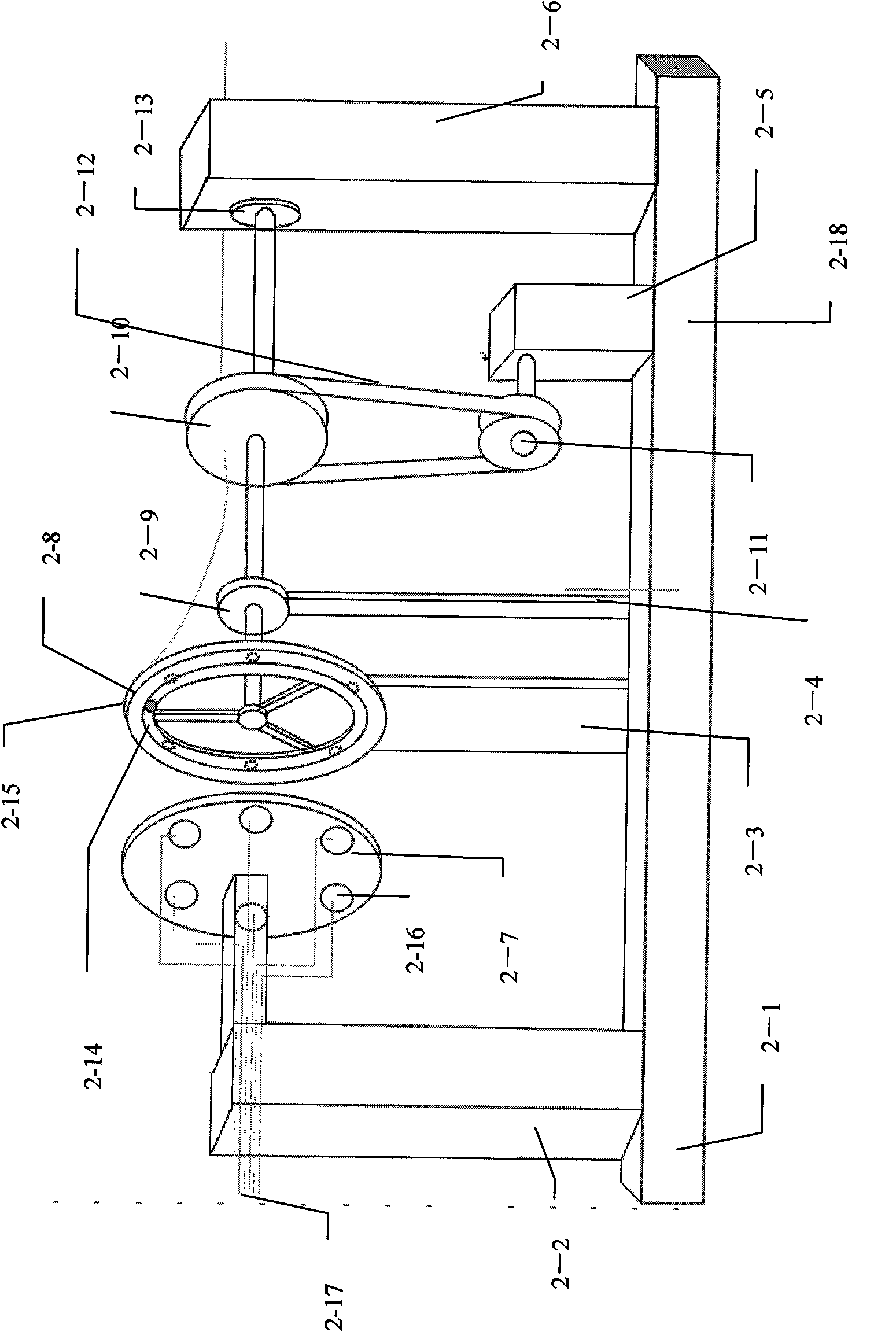

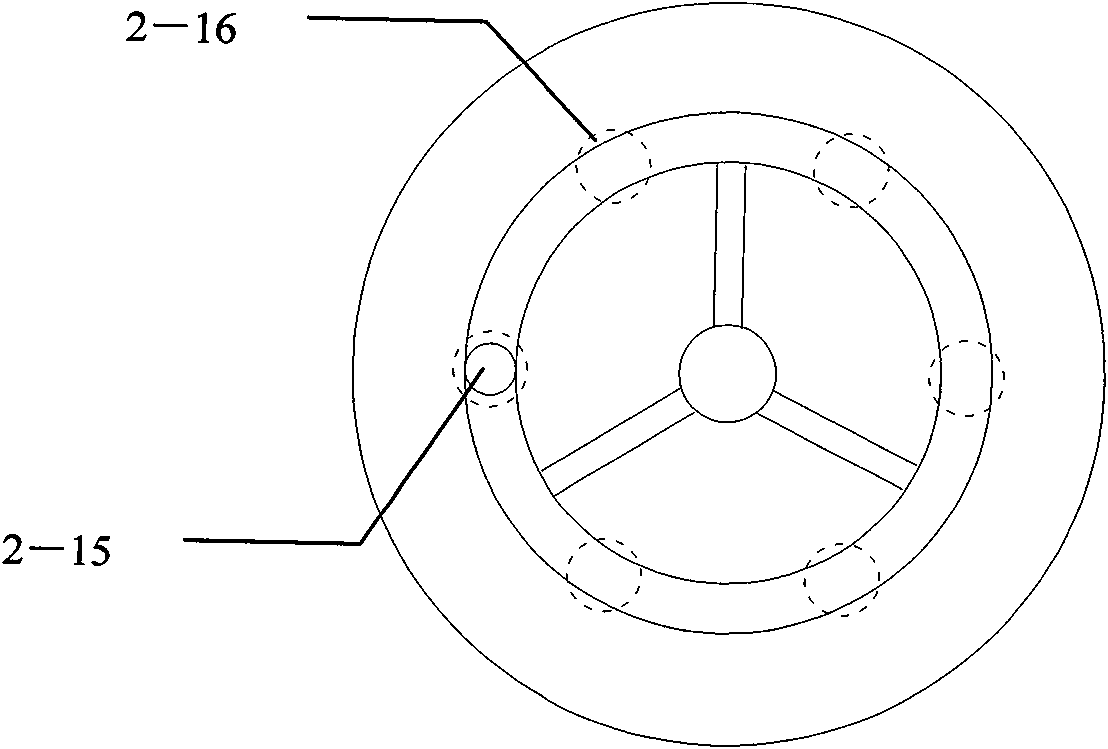

[0026] The serial test is basically similar to ordinary manual operation, and only uses automatic control to realize optical path conversion, which improves the test efficiency.

[0027] Taking the experiment of evaluating fiber rings at different temperatures as an example, this experiment needs to obtain performance data of fiber rings at low temperature, room temperature and high temperature. The experimental process is as follows: the light emitted by the SLD light source 5-1 enters the fiber ring 5-6 through the beam splitter 5-2, the Y waveguide 5-3 and the first optical path switching system 5-4, and then passes through the second optical path switching system 5- 7 Returning to the Y waveguide, the optical signal passing through the beam splitter is collected by the PIN tube 5-8, read by the lock-in amplifier 5-9, and finally processed by the data processing system.

[0028] If the circuit is manually switched and each device is tested individually, it takes time (about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com