Temperature protective dry-type air core reactor and temperature measuring method thereof

An air-core reactor, protective technology, used in emergency protection circuit devices, thermometers, emergency protection devices with automatic disconnection, etc. The effect of expanding the scope and avoiding economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

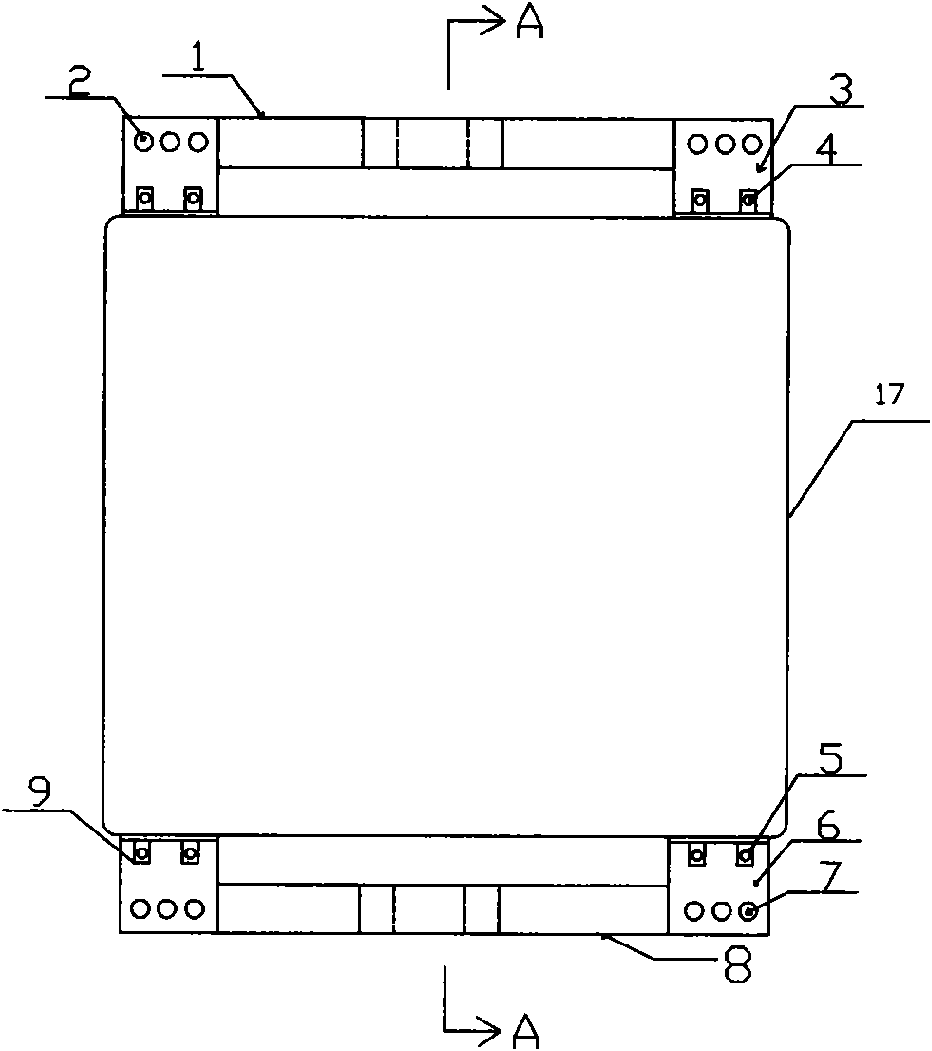

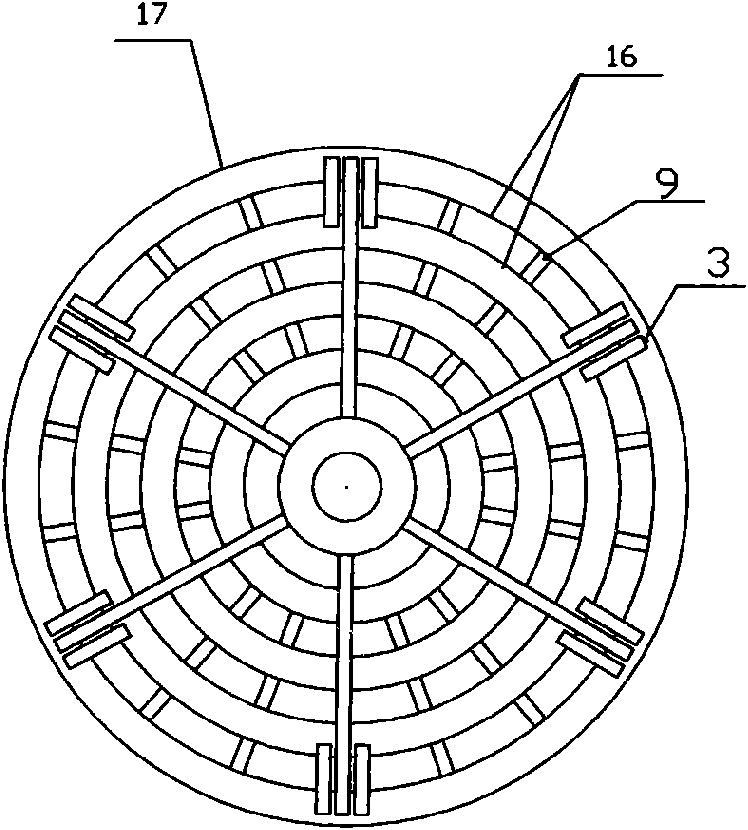

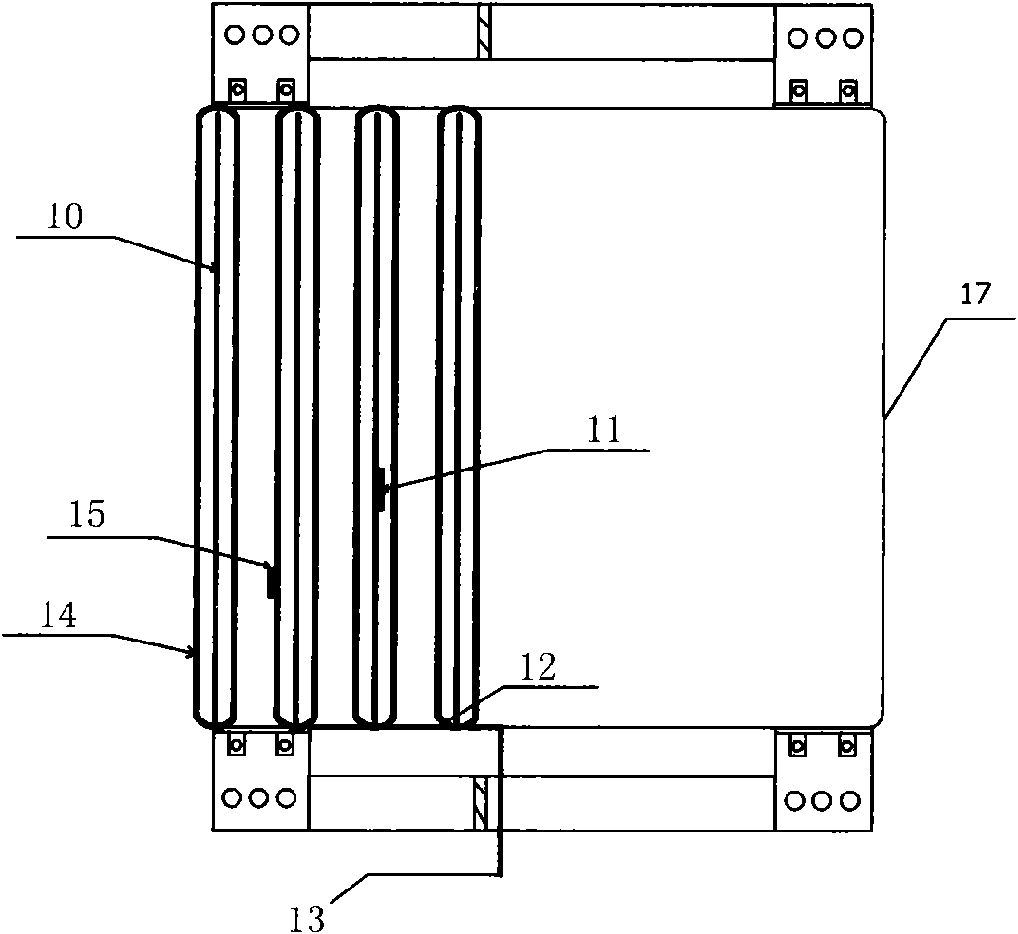

[0013] Embodiment 1: Built-in fiber optic temperature sensor

[0014] When winding the dry-type air-core reactor coil, according to the conclusion obtained from the analysis of the temperature field, the built-in optical fiber temperature sensor 11 is wrapped on the wire 10 with alkali-free glass fiber cloth, and the optical cable 13 for transmitting optical signals Adhered to the insulating outer layer of the completed coil and drawn out. The outgoing optical cable is led to the photoelectric converter ≥ 2 meters away from the dry-type air-core reactor through the embedded pipe fittings (or directly led to the photoelectric converter in the main control room. The condition is that there are not too many turns and the angle is > 90 degrees) , convert the optical signal into an electrical signal, and amplify it to the working range of the temperature controller, and the temperature controller will display the appropriate temperature at this point of the dry-type air-core reacto...

Embodiment approach 2

[0015] Embodiment 2: External fiber optic temperature sensor

[0016] When winding the dry-type air-core reactor coil, the external optical fiber temperature sensor 15 is wound on the outer insulating layer 14 with alkali-free glass fiber cloth, and the epoxy resin of the dry-type air-core reactor is cured as a whole. Firmly attached to the surface of the coil insulation layer. And lead the optical cable 13 for transmitting the optical signal to the photoelectric converter along the insulating outer layer. By mastering the difference between the actual temperature of the coil and the temperature of the outer insulating layer, program a correction coefficient for the temperature controller, and use the principle that the refractive index of the light will change with the temperature when it is transmitted in the temperature-sensitive material, but the refractive index of the fiber core remains unchanged. , by detecting the comparison between the output light intensity and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com