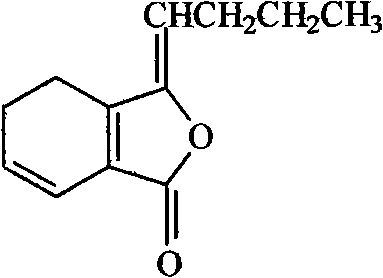

Extracting method of angelica ligustilide

A technique of ligustilide and an extraction method, which is applied in the field of extraction of ligustilide of Angelica sinensis, can solve the problems of unstable ligustilide monomer, easy to accelerate oxidative dehydrogenation of ligustilide, etc., and achieves reduction of excessive ligustilide. The effect of impurity components, the effect of improving yield, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the extraction method of a kind of angelica ligustilide of the present invention, its step is:

[0017] (1), using CO 2 Supercritical extraction of volatile oil of Angelica sinensis: Take the crude fraction of Angelica sinensis through a 40-mesh sieve, put it in an extraction kettle, and pass it through CO with a flow rate of 15L / h under an extraction environment with an analysis temperature of 25°C and an analysis pressure of 6Mpa. 2 , extracted for 1.5 hours to obtain the crude product of angelica volatile oil;

[0018] (2), the acquisition of the neutral oil part of Angelica sinensis: the above-mentioned crude volatile oil is extracted with 1% NaOH solution to obtain the neutral oil part of Angelica sinensis;

[0019] (3) Separation of ligustilide: dry the neutral oil over anhydrous sodium sulfate, put it on a silica gel column, and elute with a mixed solvent gradient of n-hexane: acetone, and use GC-MS as a detection method to collect ligustilide The...

Embodiment 2

[0021] Embodiment 2: the extraction method of a kind of angelica ligustilide of the present invention, its step is:

[0022] (1), using CO 2 Supercritical extraction of volatile oil of Angelica sinensis: Take the crude fraction of Angelica sinensis through a 40-mesh sieve, put it in an extraction kettle, and pass it through CO with a flow rate of 20L / h under an extraction environment with an analysis temperature of 35°C and an analysis pressure of 7.5Mpa. 2 , extracted for 2 hours to obtain the crude product of Angelica sinensis volatile oil;

[0023] (2), the acquisition of the neutral oil part of Angelica sinensis: the above-mentioned crude volatile oil is extracted with 1% NaOH solution to obtain the neutral oil part of Angelica sinensis;

[0024] (3) Separation of ligustilide: dry the neutral oil over anhydrous sodium sulfate, put it on a silica gel column, and elute with a mixed solvent gradient of n-hexane: acetone, and use GC-MS as a detection method to collect ligusti...

Embodiment 3

[0026] Embodiment 3: the extraction method of a kind of angelica ligustilide of the present invention, its step is:

[0027] (1), using CO 2 Supercritical extraction of volatile oil of Angelica sinensis: Take the crude fraction of Angelica sinensis through a 40-mesh sieve, place it in an extraction kettle, and pass it through CO with a flow rate of 25L / h under an extraction environment with an analysis temperature of 40°C and an analysis pressure of 8Mpa. 2 , extracted for 2.5 hours to obtain the crude product of angelica volatile oil;

[0028] (2), the acquisition of the neutral oil part of Angelica sinensis: the above-mentioned crude volatile oil is extracted with 1% NaOH solution to obtain the neutral oil part of Angelica sinensis;

[0029] (3) Separation of ligustilide: dry the neutral oil over anhydrous sodium sulfate, put it on a silica gel column, and elute with a mixed solvent gradient of n-hexane: acetone, and use GC-MS as a detection method to collect ligustilide T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com