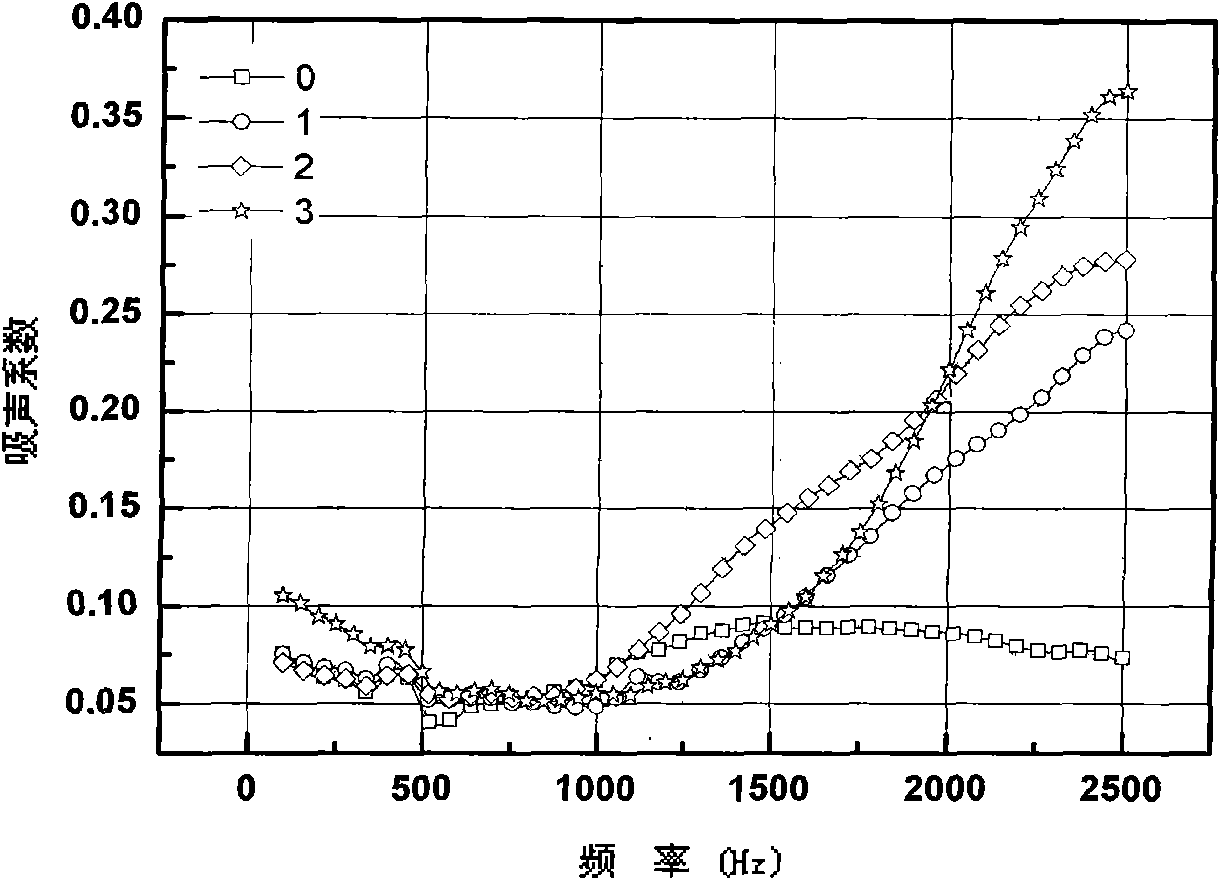

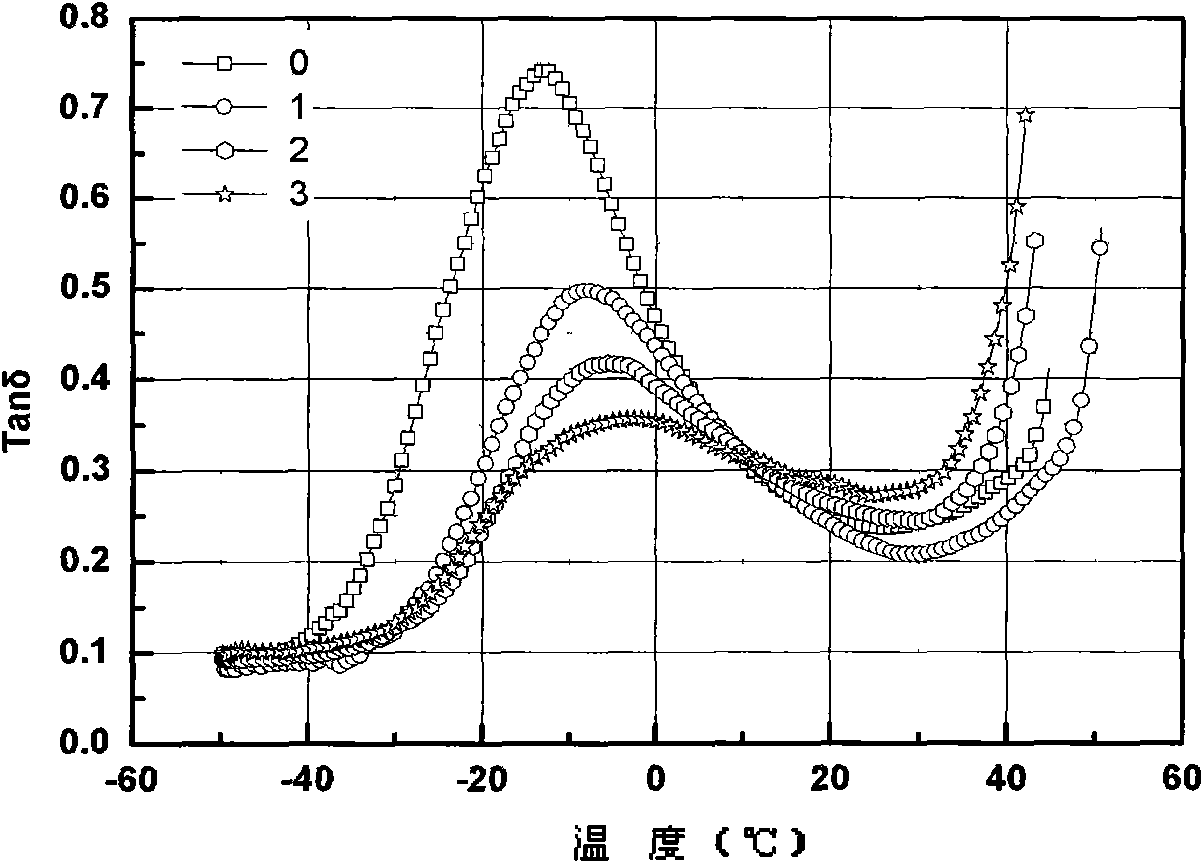

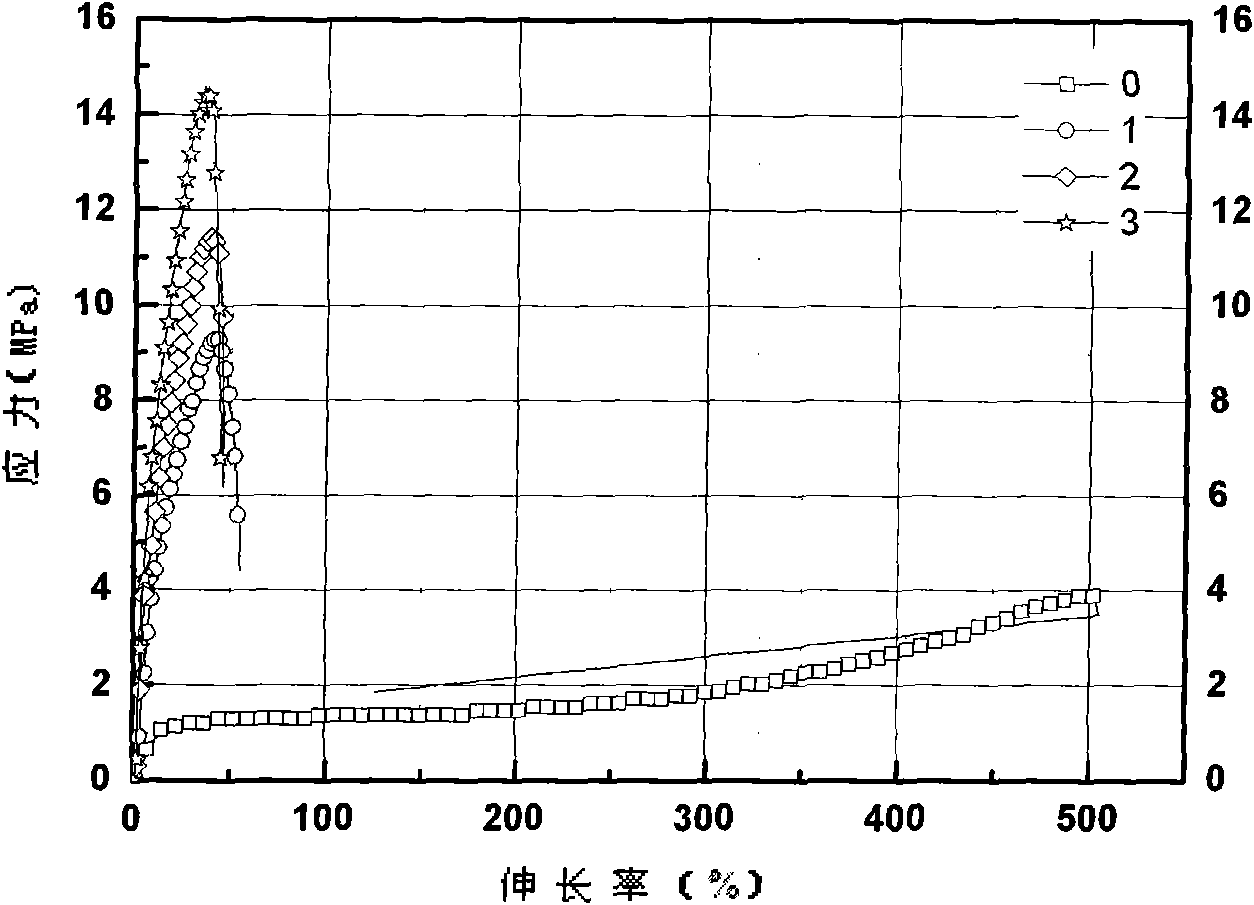

Composite material with functions of sound absorption and damping vibration attenuation

A composite material and damping technology, which is applied in the field of vibration-absorbing composite materials and its preparation, can solve the problems of poor mechanical properties of porous materials, and achieve the effects of widening the action temperature range, simple operation, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The volume percentage of each component of the new sound-absorbing and damping composite material adopts CPE:SHPF=100:15 (20:3), and the preparation steps of the composite material are as follows:

[0031] The first step of mixing:

[0032] 1> Raise the temperature of the rollers on the double-roller plastic refining machine to 65°C and keep it basically stable;

[0033] 2> Add CPE with a weight of 100 parts between the rollers, and make the CPE into sheets through the surface temperature of the rollers and the pressure of the rollers, and it will be in a viscous flow state between the rollers;

[0034] 3> Add SHPF with a weight of 15 parts between the rollers, and use a cutter to assist mixing to make the components evenly mixed;

[0035] 4> The total mixing time is 40 minutes. After mixing evenly, peel the mixed material from the roller and cool it at room temperature for hot pressing.

[0036] The second step of thermoforming:

[0037] 1> Spread the cooled mixed f...

Embodiment 2

[0042] The weight percentage of each component of the novel sound-absorbing composite material with damping and vibration reduction is CPE: SHPF=100:20 (20:4). The preparation steps of the composite material are the same as in Example 1, and the process is different from that in Example 1. The same thing is:

[0043] 1>The temperature is 65°C when the raw materials are evenly mixed on the double-roller plasticizing machine, and the mixing time is 50 minutes.

[0044] 2> Hot press the sample under the flat vulcanizing machine, the temperature is 160 ℃, and the preheating time is 20 minutes under the condition of no pressure.

[0045] 3> Pressurize with a pressure of 15Mpa for 20 minutes, and finally take out the material and cool it in ice water to obtain a composite material with high-performance vibration reduction and sound absorption.

Embodiment 3

[0047] The volume percentage of each component of the new sound-absorbing and damping composite material adopts CPE: SHPF=100:25 (20:5). Embodiment 1 is different in that:

[0048] 1> The temperature of the raw materials is 70°C when they are uniformly mixed on the double-roller extruding machine, and the mixing time is 60 minutes;

[0049] 2> Hot press the sample under the flat vulcanizing machine, the temperature is 180 ℃, and the preheating time is 30 minutes under the condition of no pressure.

[0050] 3> Pressurize for 30 minutes with a pressure of 18Mpa, and finally take out the material and cool it in ice water. In this way, a composite material with high-performance vibration reduction and sound absorption is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com