Method for controlling flow of transmission control system of paper machine

A process control and transmission control technology, applied in sequence/logic controller for program control, paper machine, paper making, etc., can solve problems such as disadvantageous operator discrimination, less sub-function calls, and increased application cost, and improve system performance. Safety and fault diagnosis capabilities, increased control information, yield and quality benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

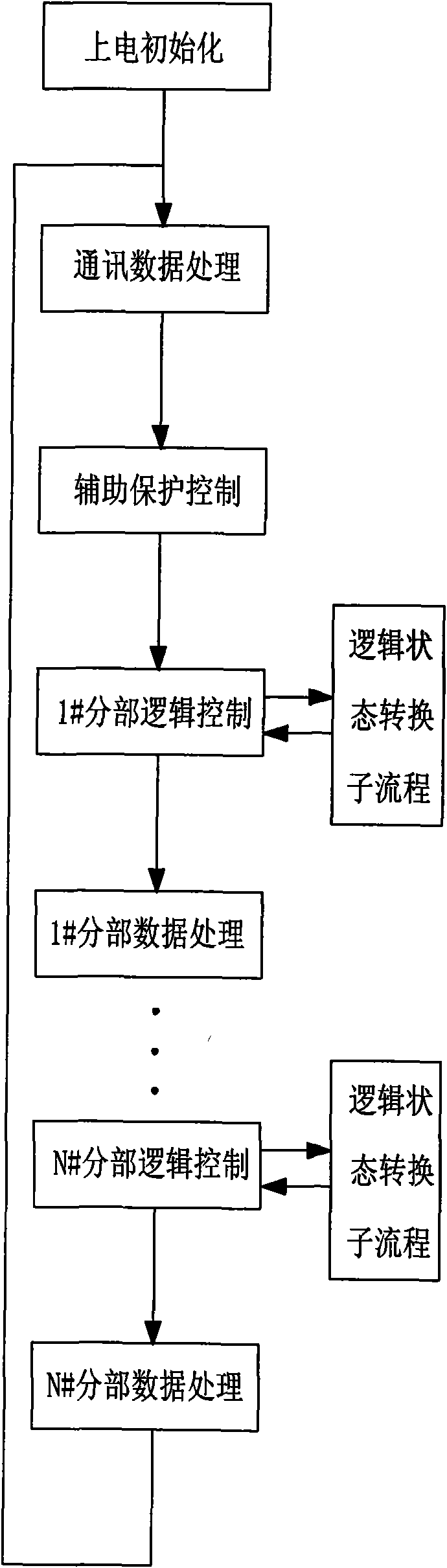

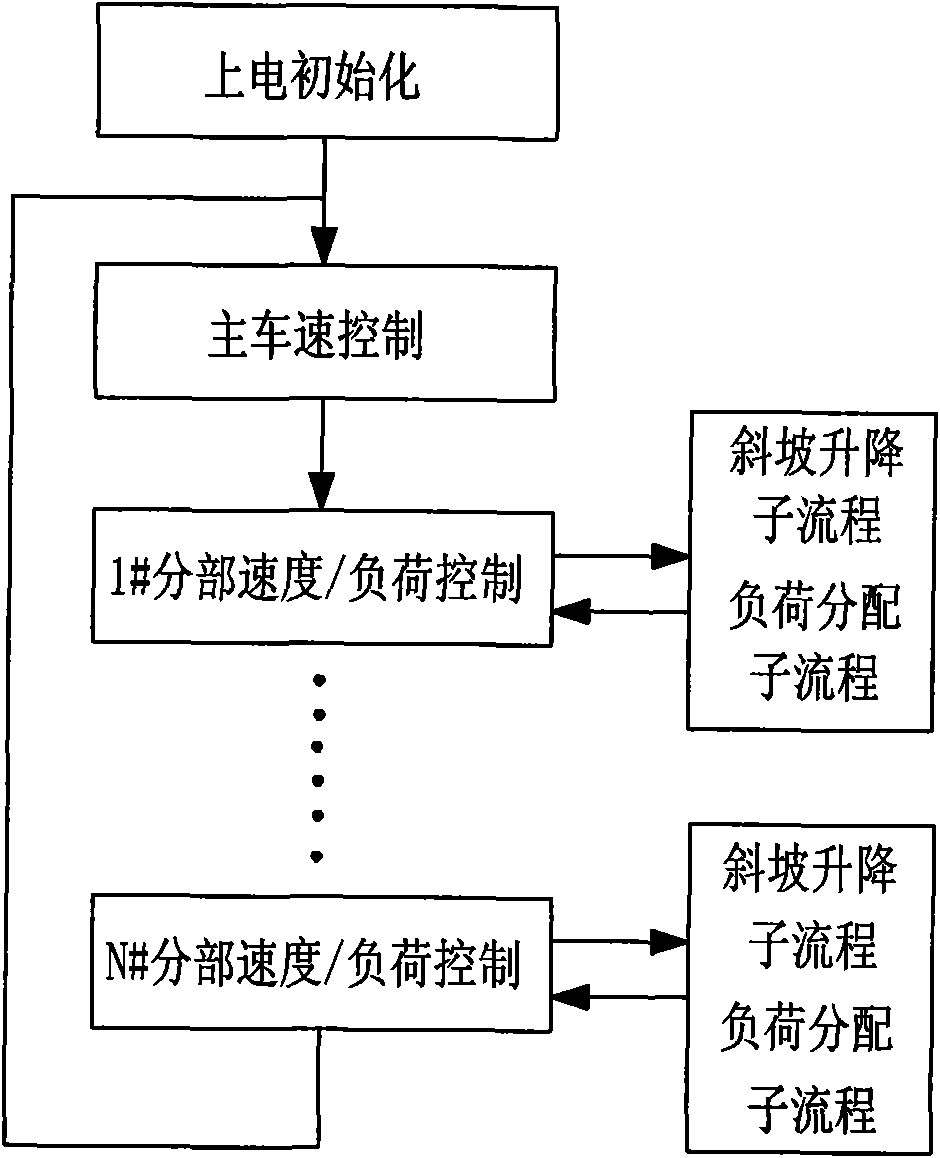

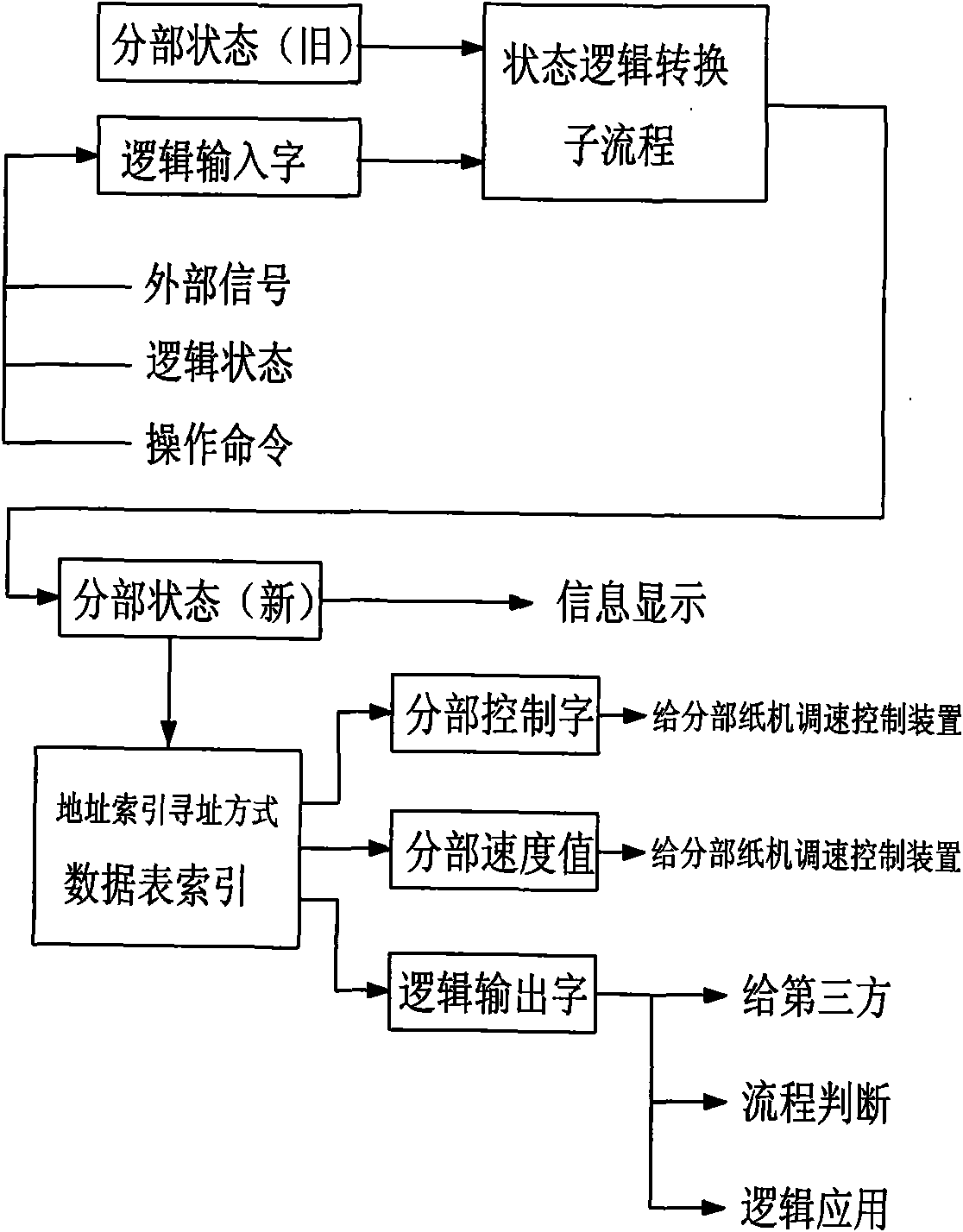

[0044] The process control method for the transmission control system of a paper machine adopts a control system including a programmable control device PLC, a speed regulating device and a field bus for process control. The process control method modularizes the control operation process of the functions of preparation, operation, crawling, parking, cleaning and fault handling included in the transmission control system of the paper machine, and uses the process control module to perform the functional control operation. The process control module sets 10 to 50 branch states according to the functions controlled by the drive system of the paper machine. There are 16 sub-states including jog stop, forward crawl, normal operation, sub-section stop, reverse creep, safety stop, emergency stop, cleaning operation, sub-section fault and fault reset. The process control module adopts the address index addressing mode to carry out the logical conversion of each branch, data processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com