Device and process for extracting oil in oil-containing solid waste and recovering extracting agent

An extraction agent and extraction technology, applied in solid solvent extraction, solid waste removal, solvent extraction, etc., can solve the problems of unstable test data and results, and no clear guiding significance for large-scale industrial trial production, etc., to achieve process parameters Stable and reliable, small footprint, safe process reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

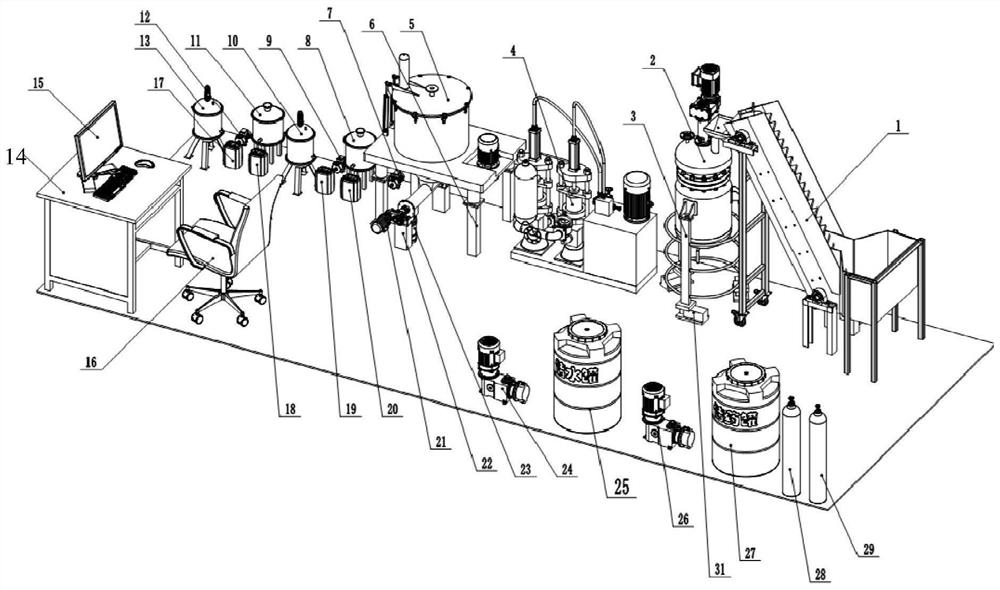

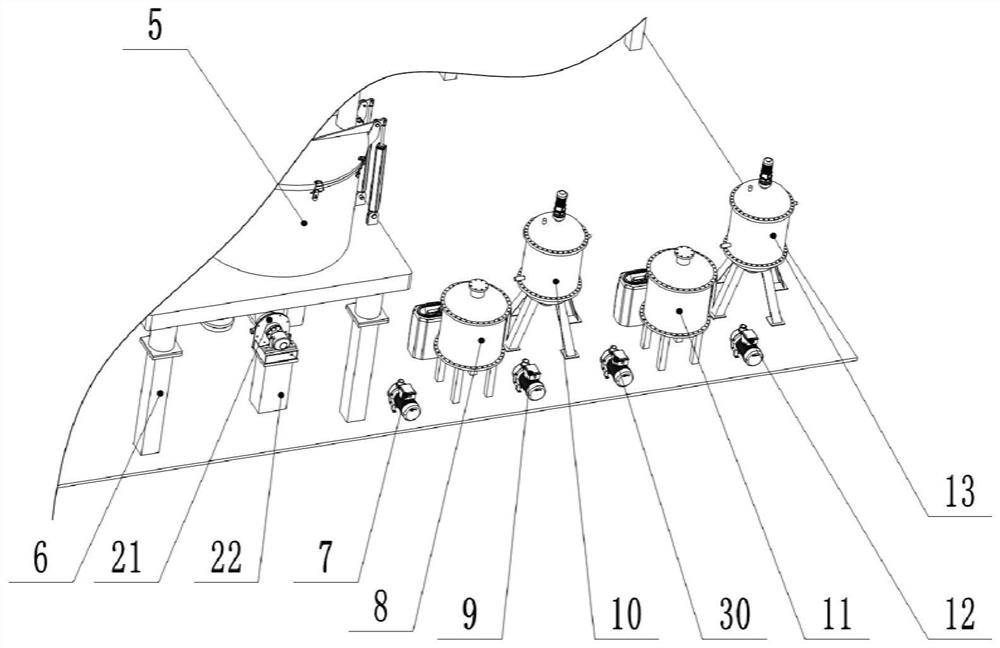

[0092] This example provides a device for oil extraction and extraction agent recovery from oily solid waste, the schematic diagram of which is shown in figure 1 As shown, the side view is as figure 2 shown, from figure 1 and figure 2 As can be seen, the device includes:

[0093] Closed feeding machine 1, stirring reaction kettle 2, solid-liquid separation centrifuge 5, first separator 8, second separator 10, third separator 11, fourth separator 13, water tank 25, medicine tank 27, Gas A bottle 28, gas B bottle 29;

[0094] The closed feeder 1 is used to transport the oil-containing solid waste into the stirred reactor 2, and the water tank 25 and the medicine tank 27 react with the stirring reaction via the water pump 24 and the medicine pump 26 respectively through pipelines. Kettle 2 connected;

[0095] The stirring reactor 2 is placed on the reactor supporting frame 3, and a load cell 31 is arranged under the stirring reactor 2; the solid-liquid separation centrifug...

Embodiment 2

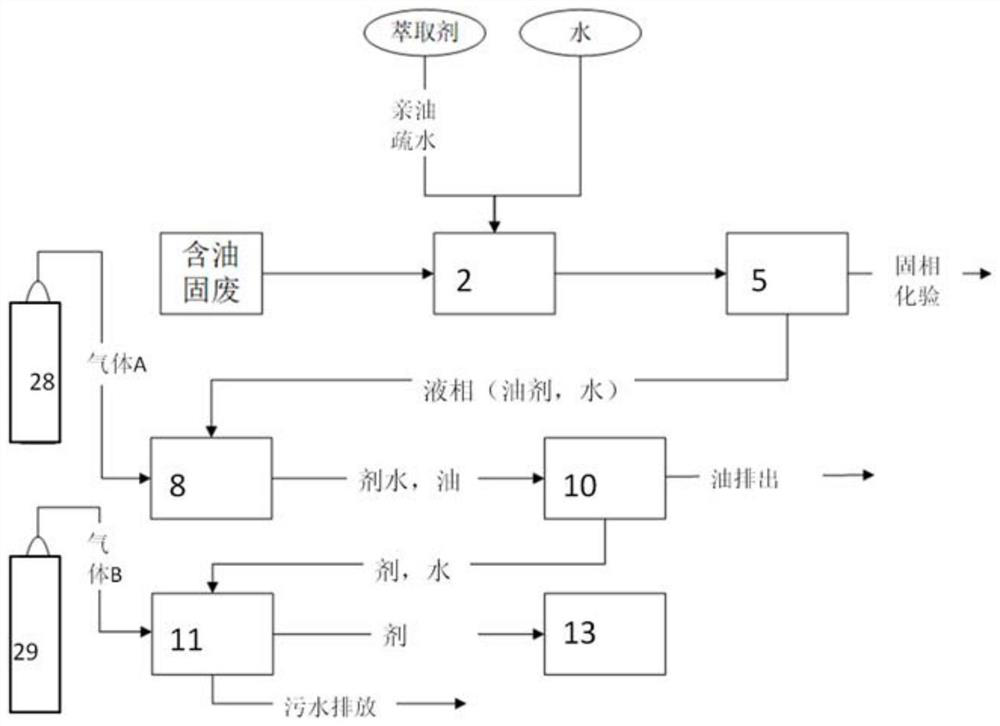

[0104] This embodiment provides a process for oil extraction and extraction agent recovery from oily solid waste. The process is realized by using the device for oil extraction and extraction agent recovery from oily solid waste provided in Example 1. The process flow Figure such as image 3 shown, from image 3 It can be seen that the process includes the following specific steps:

[0105] (1) Stir and mix the oily solid waste, the initial state of lipophilic and hydrophobic extractant and water in the stirring reactor 2 according to a certain ratio, so as to extract the oil in the oily solid waste;

[0106] (2) carrying out solid-liquid separation in the solid-liquid separation centrifuge 5 with the mixed solution gained in step (1);

[0107] (3) inject the mixed solution gained after the solid-liquid separation in step (2) into the first separator 8, and feed gas A into the first separator 8 simultaneously to change the state of the extractant into hydrophilic and oleopho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com