A method for preparing metal honeycomb material by low-pressure injection molding

An injection molding, metal honeycomb technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of low mechanical/laser drilling processing efficiency, insufficient reliability of honeycomb structure, limited thickness of parts, etc., and achieve accurate process parameters Reliable, low cost, reduced pressure requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

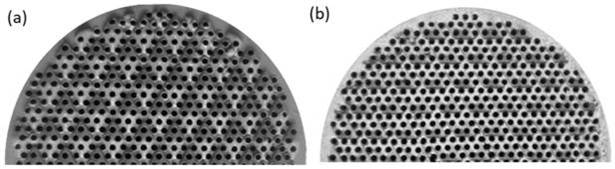

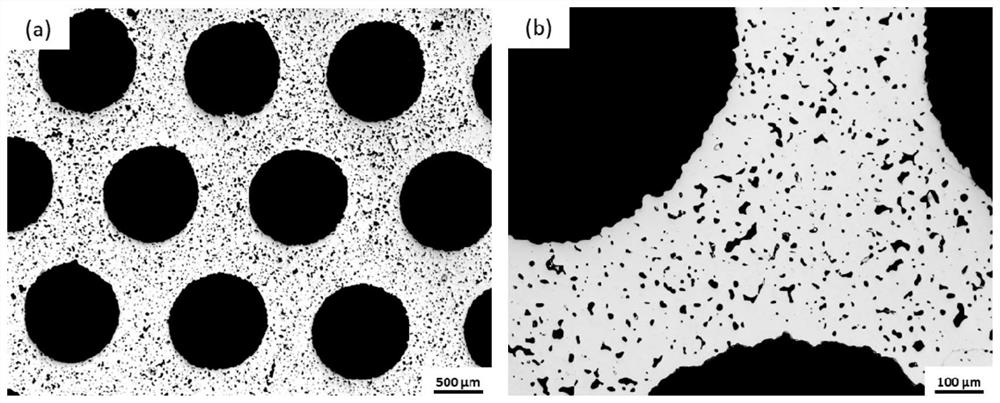

[0042] Embodiment 1: Preparation of FeCrAl metal honeycomb body

[0043] (1) Mixing; heat the paraffin to 120°C, slowly add ethylene vinyl acetate and stearic acid, and mix thoroughly with mechanical stirring. The quality of the binder is composed of 83 parts of paraffin, 15 parts of ethylene-vinyl acetate, and 2 copies;

[0044] The FeCrAl pre-alloyed powder (<45μm) was heated to 100°C and then mechanically mixed with 20% of the total weight of the binder for 5min.

[0045](2) Molding: FeCrAl powder-binder mixed raw materials are added to a low-pressure injection molding material cylinder, vacuumized after sealing, heated to 110°C, and mechanically stirred for 30 minutes.

[0046] The slurry is injected into the mold under the pressure of 0.7MPa to make the honeycomb green body.

[0047] (3) Degreasing: take out the green honeycomb and put it into a dichloromethane solution, soak it at 40°C for 12h, take it out, and dry the residual solvent at 90°C.

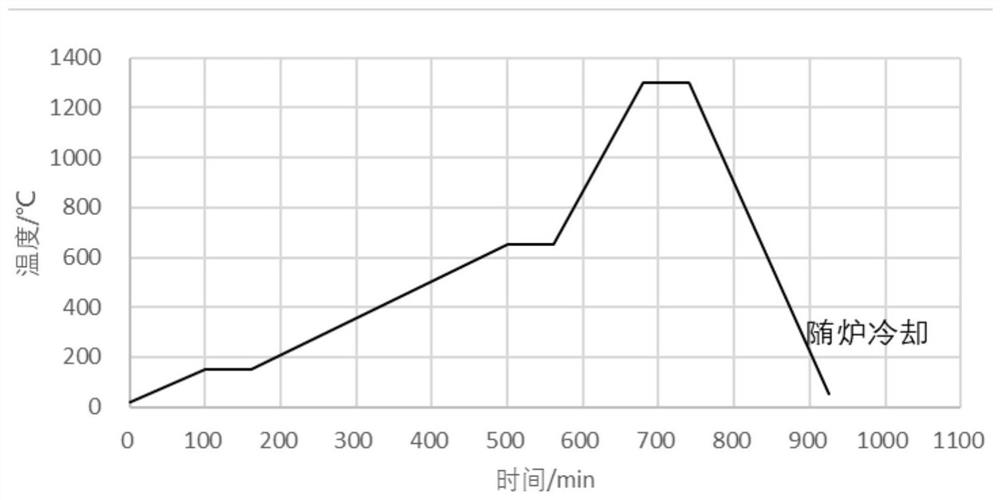

[0048] (4) Thermal de...

Embodiment 2

[0053] Example 2: Preparation of 304 stainless steel metal honeycomb body

[0054] (1) Mixing: heat the paraffin to 120°C, slowly add low-density polyethylene and stearic acid and mix thoroughly, the quality of the binder is composed of 74 parts of paraffin, 22 parts of low-density polyethylene, and 4 parts of stearic acid;

[0055] 304 stainless steel pre-alloyed powder (<45μm) was heated to 100°C, and then pre-mixed with 15% of the total weight of binder for 5 minutes.

[0056] (2) Molding: Add 304 stainless steel powder-binder mixed raw materials into the low-pressure injection molding material cylinder, vacuumize after sealing, heat to 110°C, and mechanically stir for 30 minutes.

[0057] The slurry is injected into the mold under the pressure of 1.0MPa to make the honeycomb green body

[0058] (3) Degreasing: take out the honeycomb blank and put it into trichlorethylene solution, soak it at 45°C for 15h, take it out, and dry the residual solvent at 90°C.

[0059] (4) Th...

Embodiment 3

[0062] Embodiment 3: Preparation of FeCrAl metal honeycomb body

[0063] (1) Mixing: Premix the binder (70 parts of paraffin wax, 25 parts of ethylene-vinyl acetate and 5 parts of stearic acid) and heat it to melt, then preheat the metal powder (particle size smaller than 45μm FeCrAl heat-resistant alloy powder) was poured into the molten binder and stirred thoroughly to obtain a uniform powder-binder mixed raw material, in which the mass ratio of metal powder to binder was 9:1.

[0064] (2) Molding: the powder-binder mixed raw material is obtained by low-pressure injection molding to obtain a porous honeycomb blank; the process conditions of the low-pressure injection molding are: temperature 90°C, pressure 0.5MPa; mechanical stirring is used to strengthen the slurry during the injection molding process The uniformity of the material, the rotation speed is 500r / min, and it is supplemented by vacuum degassing to eliminate the gas in the slurry.

[0065] (3) Degreasing: fully ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com