A kind of extraction method of luteolin in corn silk

A technology of luteolin and extraction method, applied in the direction of organic chemistry, etc., can solve the problems of insufficient extraction efficiency of luteolin, slow rupture of plant cell walls, uneven distribution of ultrasonic energy, etc., achieve accurate and reliable process parameters, and avoid complicated instruments. Depends on the effect of shortening the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0038] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

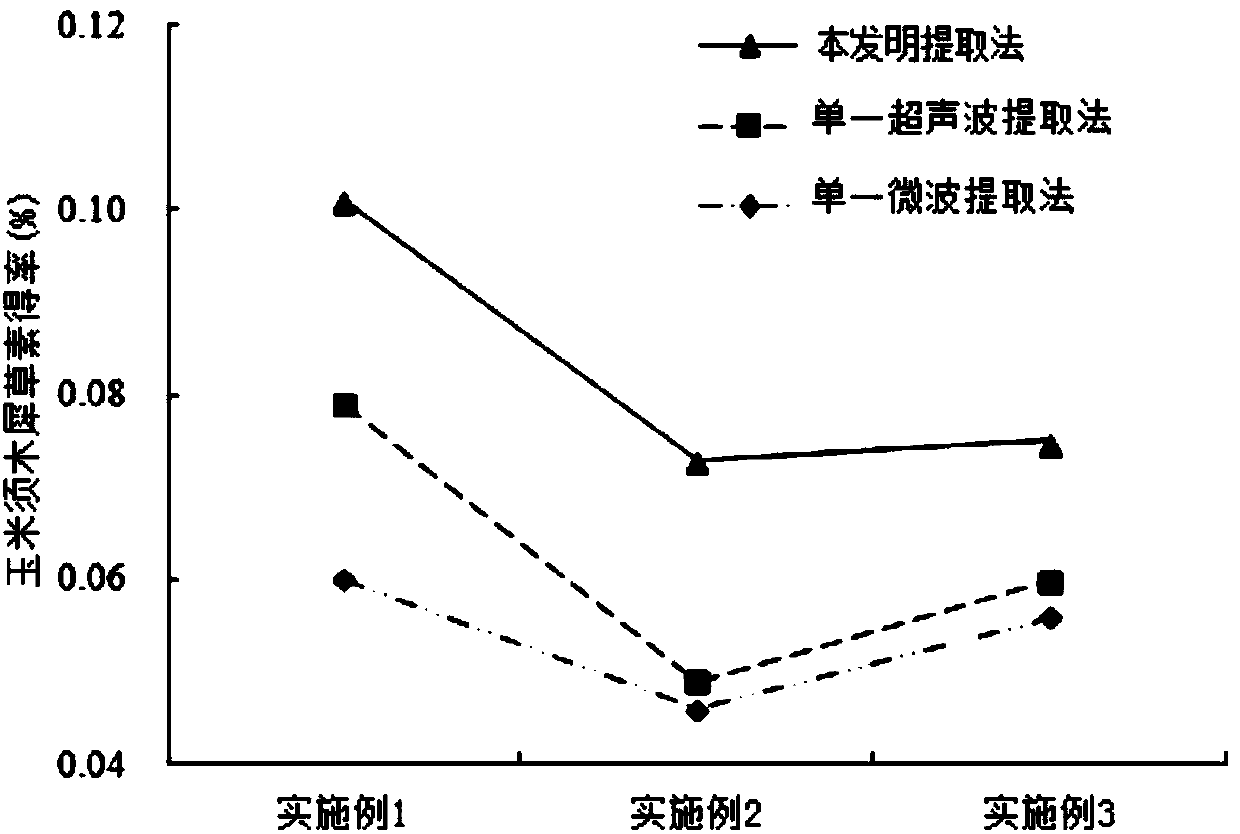

[0039] The invention adopts microwave and ultrasonic waves to extract luteolin in corn silk in stages, takes the yield of luteolin as an evaluation index, and determines the process parameters of the microwave extraction stage and the ultrasonic extraction stage. The specific process route is as follows:

[0040] Raw material processing→microwave extraction→ultrasonic extraction→centrifugation→maize luteolin sample solution→decompression concentration→storage

[0041] The present invention adopts a microwave-ultrasound-assisted method for extracting corn silk luteolin. Firstly, the corn silk is cleaned, dried, pulverized, and sieved to obtain corn silk powder. Then add ethanol solution, fully shake and seal, first conduct microwave extraction, then ultrasonic extraction, and ...

Embodiment 1

[0043] a) Raw material handling:

[0044] Washing, drying, pulverizing and passing through a 60-mesh sieve of corn silk, and storing the prepared 60-mesh corn silk powder in a dry environment for subsequent use;

[0045] b) Microwave extraction:

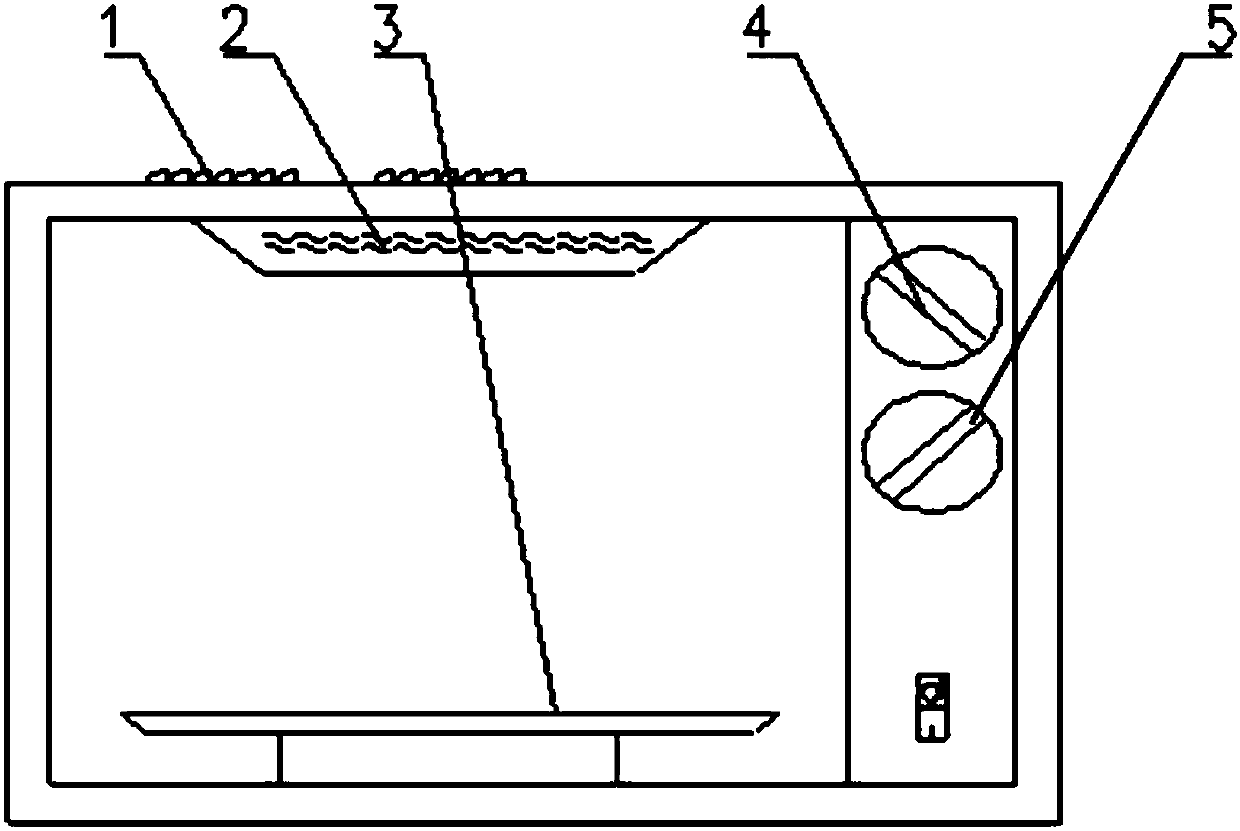

[0046] Weigh 1.0 g of corn silk powder in step a), add a volume fraction of 74% ethanol solution according to the liquid-to-solid ratio of 28 mL / g, fully shake and seal, and use such as figure 1The microwave oven shown is for microwave extraction, the microwave power is adjusted to 231W, and the microwave time is set to 49s;

[0047] c) Ultrasonic extraction:

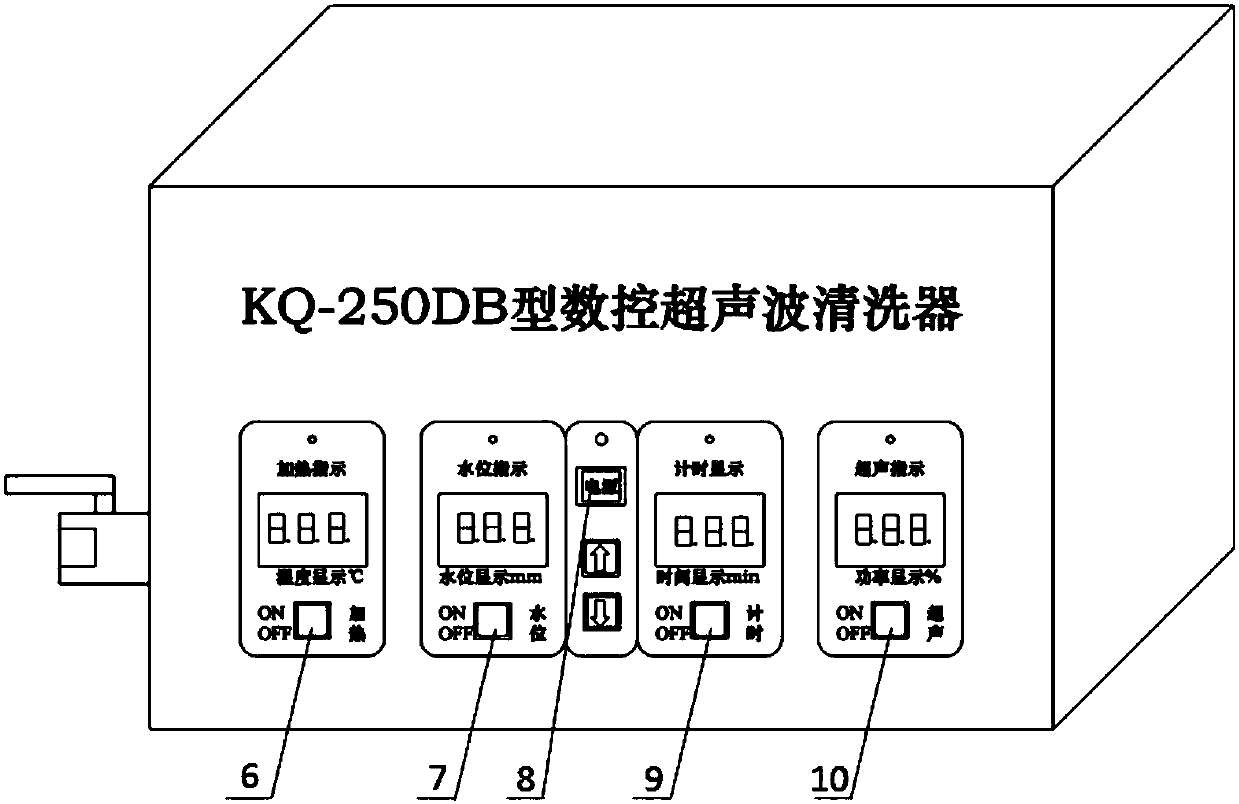

[0048] Put step b) the extract solution after microwave treatment into such as figure 2 In the KQ-250DB CNC ultrasonic cleaner shown above, ultrasonic extraction is performed, the ultrasonic temperature is adjusted to 58°C, the ultrasonic power is set to 200W, and the ultrasonic treatment time is 40 minutes;

[0049] Then centrifuge at 4000r / min for 15min to obtain corn l...

Embodiment 2

[0054] a) Raw material handling:

[0055] Washing, drying, pulverizing and passing through a 60-mesh sieve of corn silk, and storing the prepared 60-mesh corn silk powder in a dry environment for subsequent use;

[0056] b) Microwave extraction:

[0057] Weigh 1.0 g of corn silk powder in step a), add a volume fraction of 60% ethanol solution according to the liquid-to-solid ratio of 20 mL / g, fully shake and seal, and use such as figure 1 The microwave oven shown is for microwave extraction, the microwave power is adjusted to 231W, and the microwave time is set to 40s;

[0058] c) Ultrasonic extraction:

[0059] Put step b) the extract solution after microwave treatment into such as figure 2 In the KQ-250DB CNC ultrasonic cleaner shown above, ultrasonic extraction is performed, the ultrasonic temperature is adjusted to 50°C, the ultrasonic power is set to 200W, and the ultrasonic treatment time is 40 minutes;

[0060] Then centrifuge at 4000r / min for 15min to obtain corn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com