Silencer for a motor device

A technology of motorized equipment and mufflers, applied in mechanical equipment, mufflers, machines/engines, etc., can solve the problems of increasing harmful substance emissions, reducing the effective coefficient of the engine, etc., and achieve the effect of reducing scavenging loss and wide speed frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

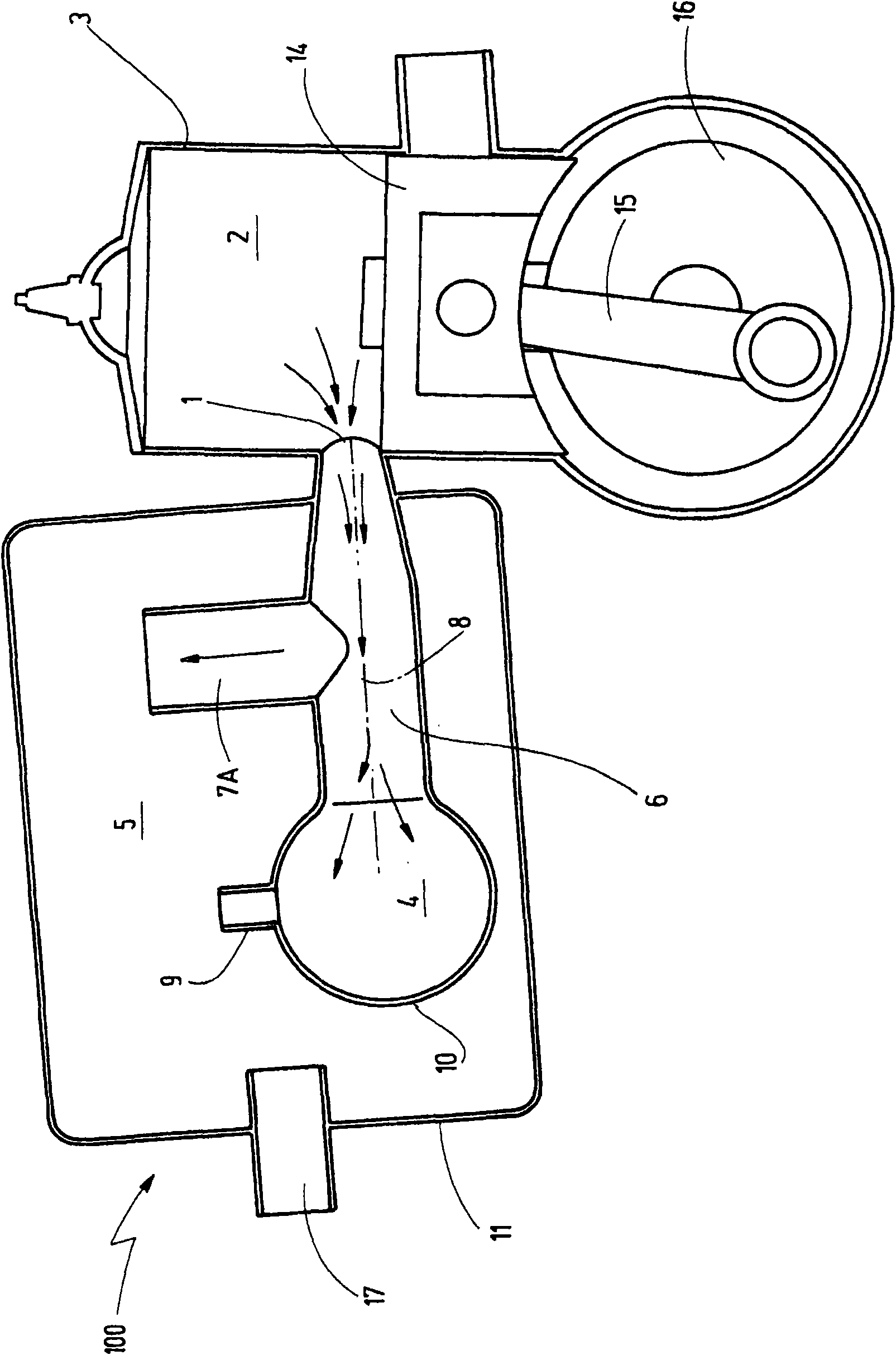

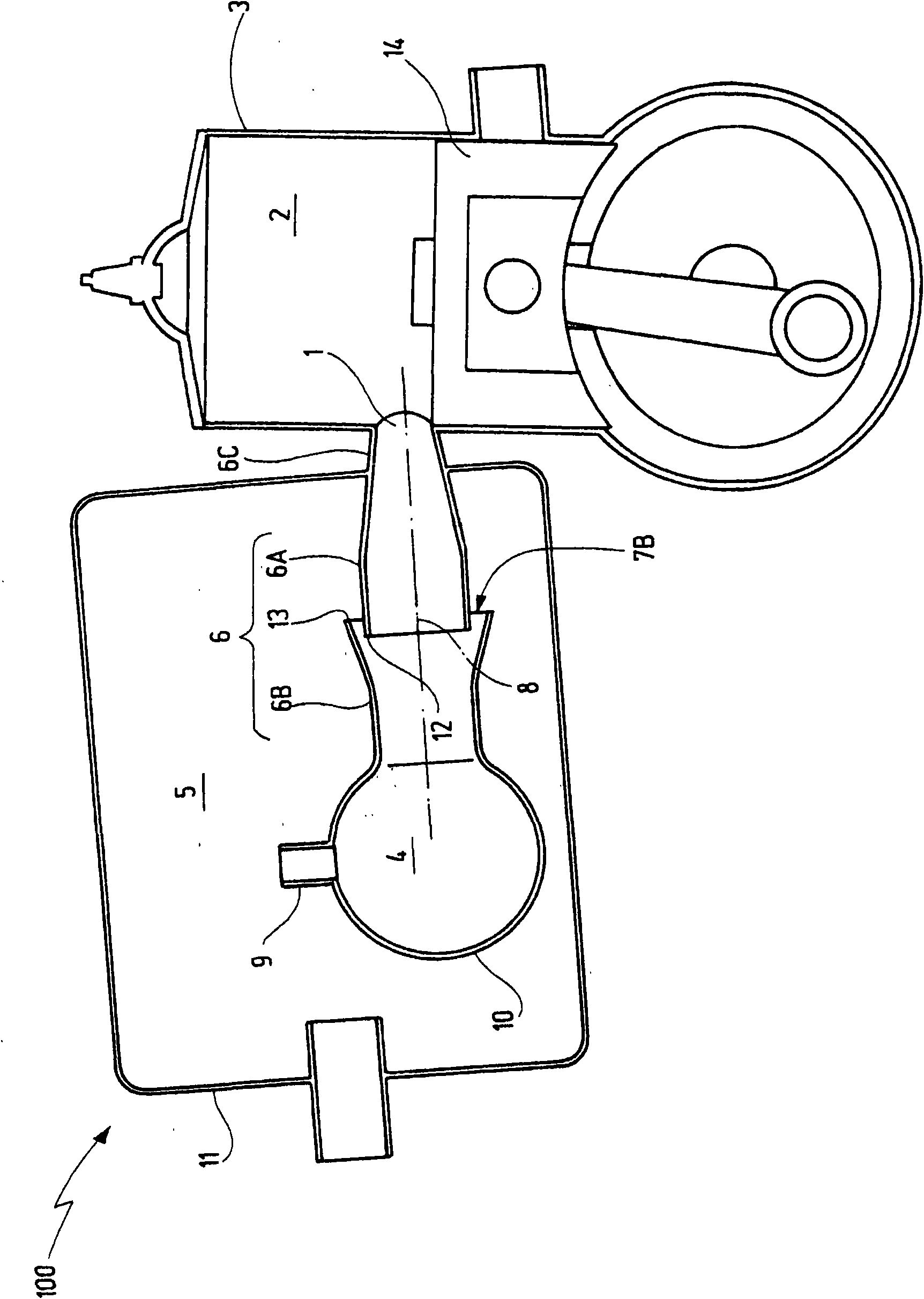

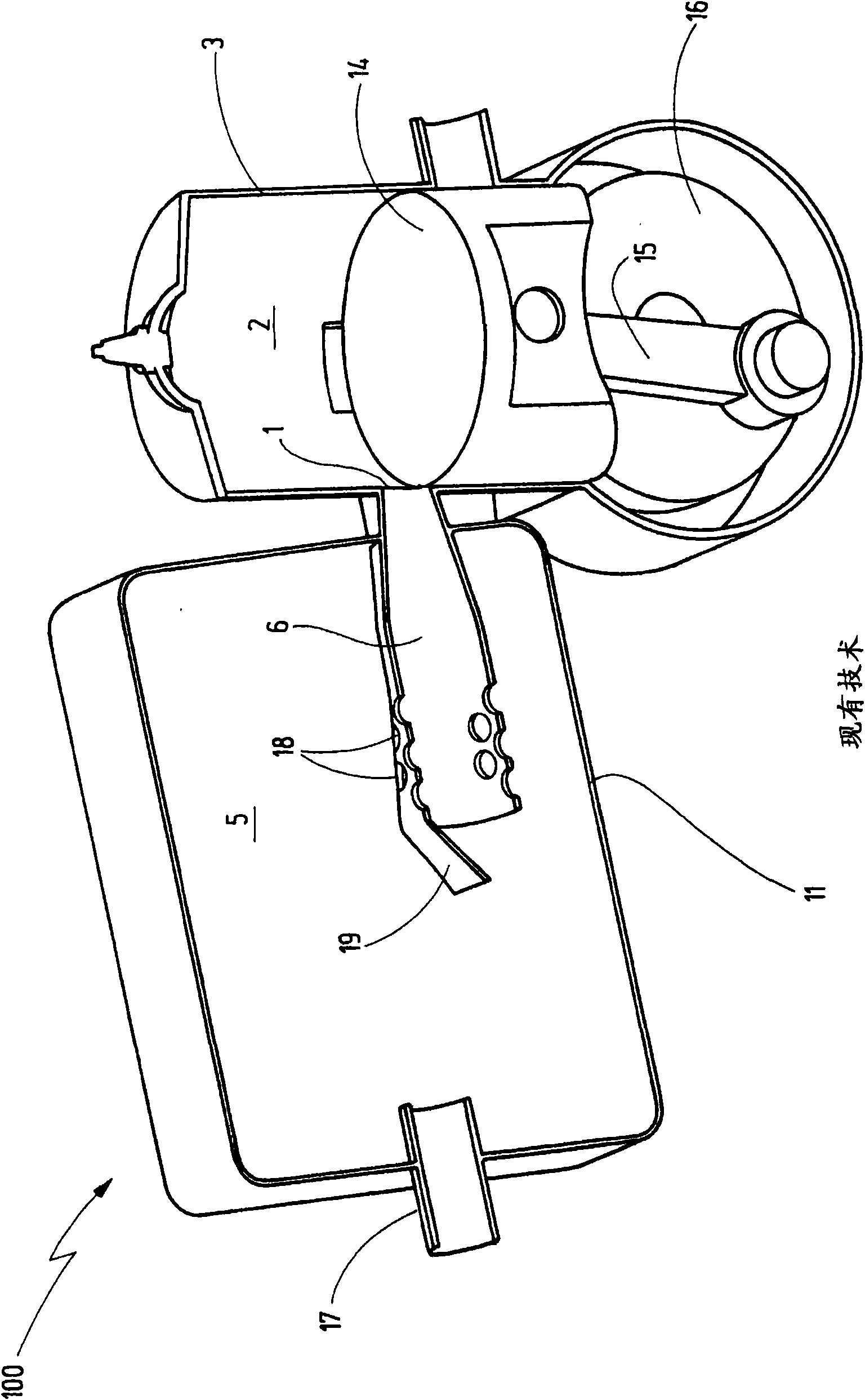

[0026] Such as figure 1 As shown, the muffler 100 is installed on the exhaust port 1 which is used to discharge the fuel-air mixture burned in the combustion chamber 2 of the piston engine 3. The piston engine 3 has a piston 14, which is connected to a crankshaft 16 by a connecting rod 15, which is suitable for driving hand-controlled gadgets, such as tools for refurbishing lawns and gardens, chainsaws, lawn mowers or Similar devices. However, this type of motorized equipment can also be used in motors for small motorcycles or speedboats.

[0027] Exhaust gas is discharged from the combustion chamber 2 through the exhaust port 1 and discharged into the flow passage 6, through which the muffler 100 can be fixed on the piston engine 3, and the combustion chamber end of the flow passage 6 and the piston type The connections between the engines 3 are simplified in illustration. The flow direction of the exhaust gas discharged into the flow channel 6 through the exhaust port 1 is indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com