Gas breaking and vacuum suction point probe device and method thereof

A technology of vacuum suction and gas crushing, which is applied to instruments, earth movers/excavators, geophysical surveys, etc., can solve the problems of no intuitive method for determining the location of underground pipelines and easily damaged underground pipelines, and achieve Increased work efficiency and large construction range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

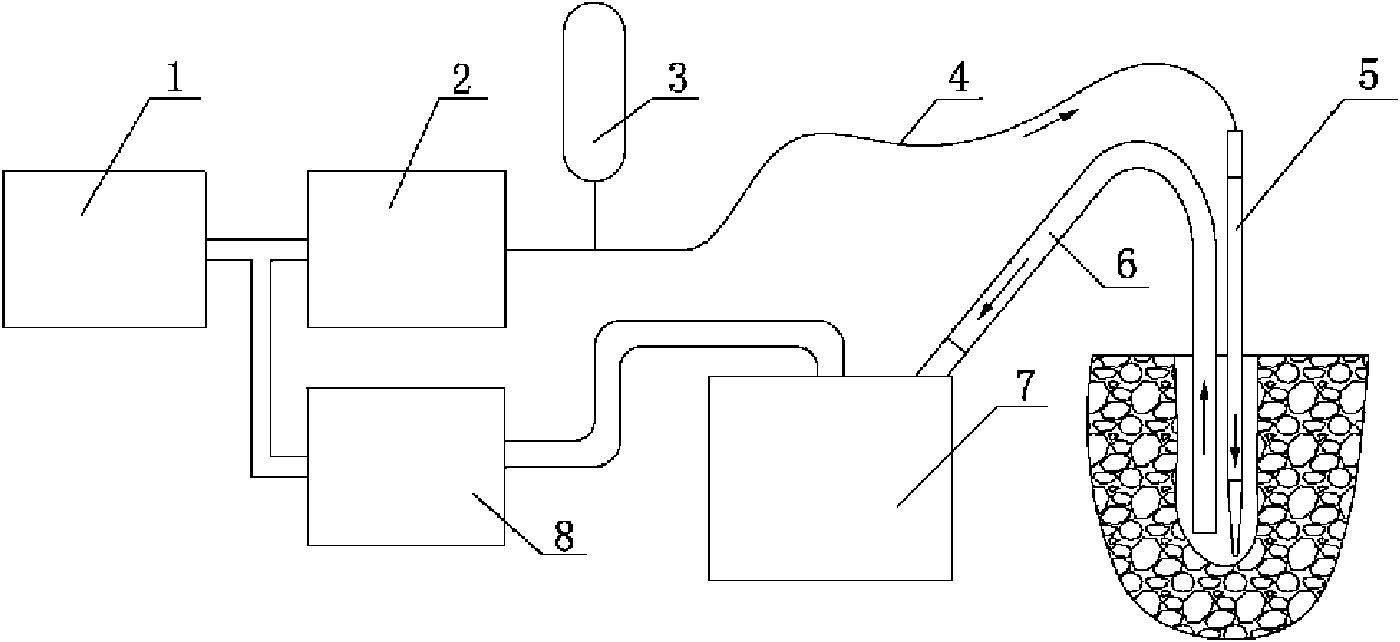

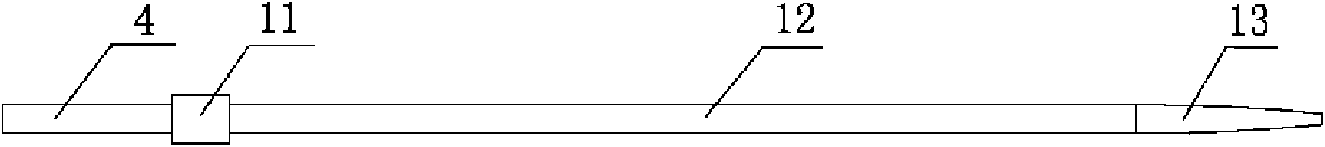

[0024] Embodiment one sees figure 1 , the gas crushing and vacuum suction spotting equipment includes a power machine 1 and a crushing device, and the power machine 1 is an electric motor, a diesel engine or a gasoline engine. The crushing device is a gas crushing device, including an air compressor 2, an air storage tank 3, a high-pressure hose 4 and a spray gun 5, wherein the air compressor 2 is driven and connected by a power machine 1, and the air compressor 2 is connected to the high-pressure soft hose through the gas storage tank 3. The pipe 4 communicates, and the high-pressure hose 4 communicates with the spray gun 5 again; the power machine 1 is also driven to connect a vacuum suction device, the vacuum suction device includes a vacuum pump 8, a storage box 7 and a suction hose 6, and the vacuum pump 8 passes through the storage box. 7 communicates with the suction hose 6. The spray gun 5 is made up of a control joint 11, a gun barrel 12 and a spray nozzle 13, which ...

Embodiment 2

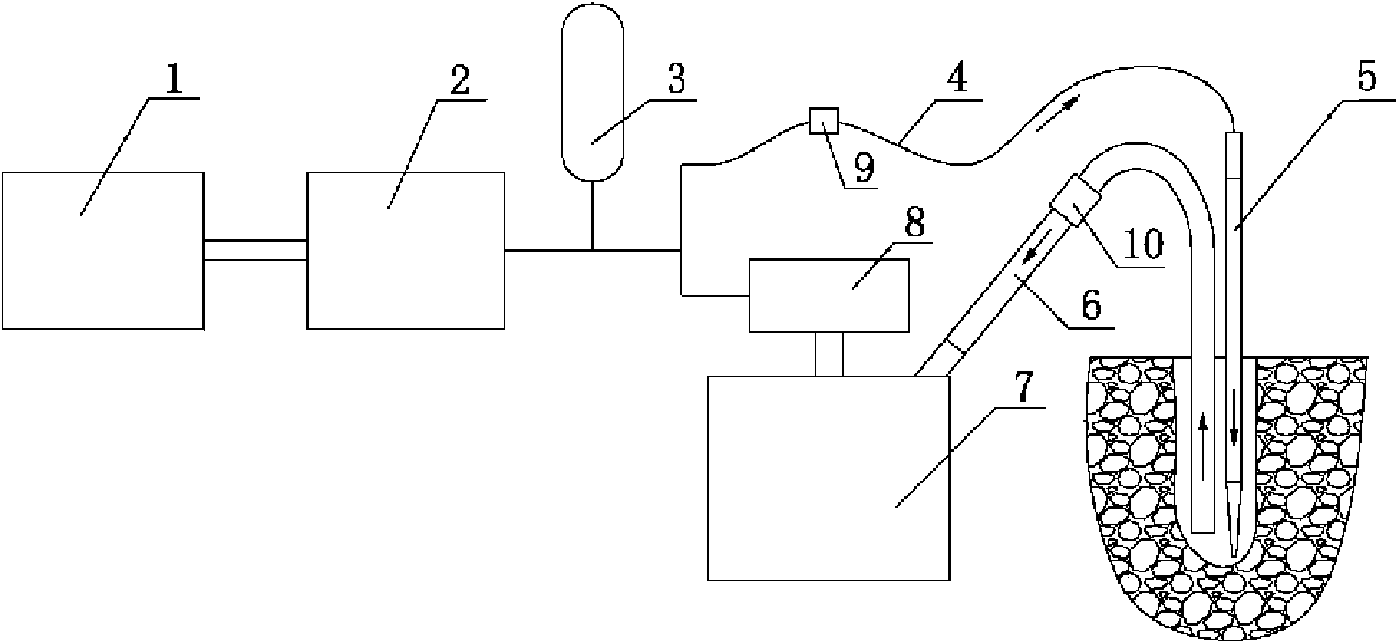

[0026] Embodiment two see figure 2 , in the specific implementation, considering that the equipment of the present invention is mostly constructed outdoors, the working environment is poor, and the fluidity is large. The required gas is purified, so that an additional purification device will be added; the vacuum pump 8 of the present invention selects a jet pump that is insensitive to the cleanliness of the sucked gas, even if rock and soil particles are sucked into the pump, it does not affect the use of the pump; at the same time The driving mode is changed to be indirectly driven by the air compressor 2, that is, the power machine 1 is driven and connected to the vacuum pump 8 through the air compressor 2 and the air storage tank 3, and the air jet pump is driven by compressed gas. The suction port of the jet pump is positioned at the top of the storage box 7, and the connection port between the suction hose 6 and the storage box 7 is also positioned at the top of the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com