Control method used for reducing rainbow occurrence in LCD production process

A control method and technology of production process, applied in the direction of liquid cleaning method, chemical instrument and method, cleaning method and utensils, etc., can solve problems such as the influence of accuracy of pressing and baking methods, inappropriate compensation design, color difference of LCD screen, etc. , to achieve the effects of reducing the incidence of rainbow defects, improving the consistency of the background color, and stabilizing the product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

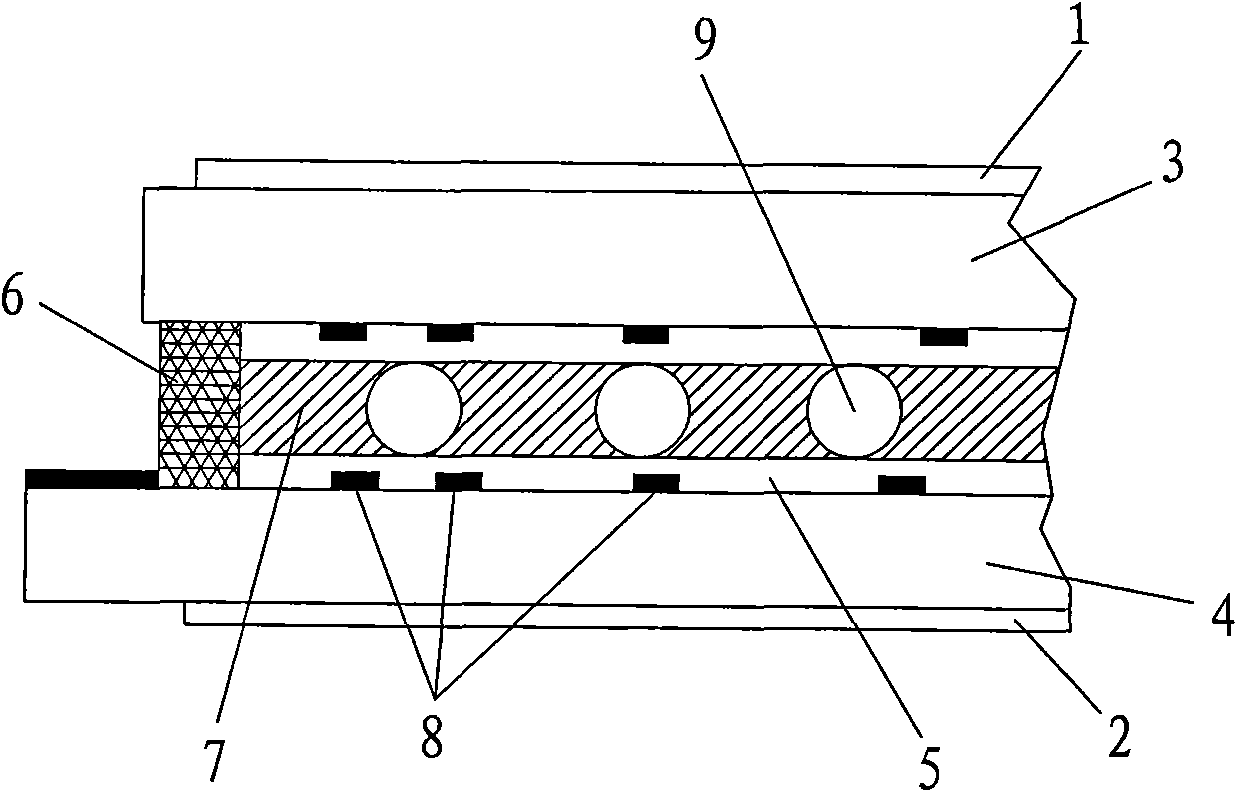

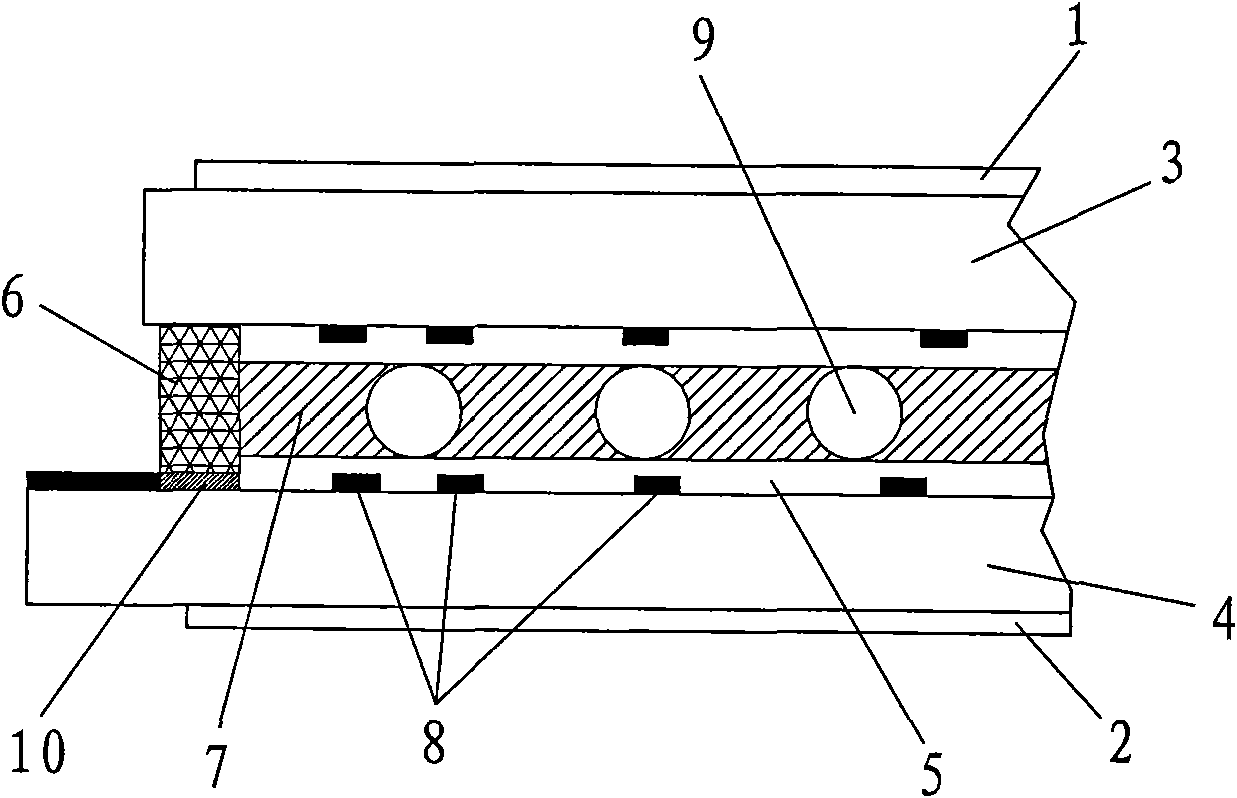

[0034] This embodiment takes the STN-LCD production process as an example for illustration, as figure 1 The box structure diagram of a conventional STN-LCD is shown. The STN-LCD unit structure usually includes: upper polarizer 1, lower polarizer 2, upper substrate ITO glass 3, lower substrate ITO glass 4, orientation material 5, frame glue 6. Liquid crystal 7, ITO layer 8, spacers 9.

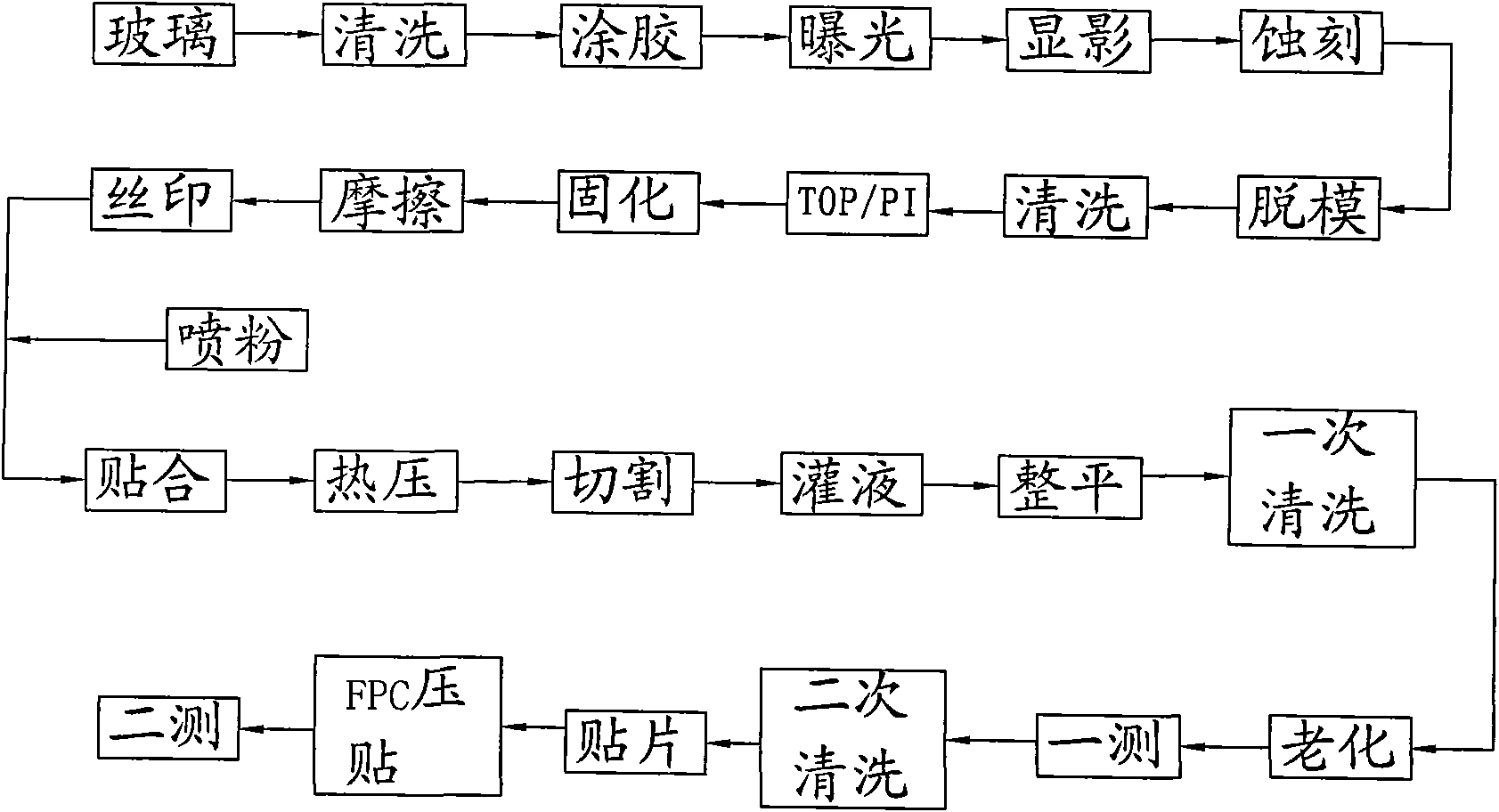

[0035] see image 3 As shown, it is a schematic diagram of the entire production process of STN-LCD production. In this embodiment, design, silk screen printing, spraying, matching, etc. are used as the focus to optimize and improve the process, that is, the design of compensation, the selection of silk screen materials, the control of spraying uniformity, The paired secondary pre-pressing and other processes are optimized; the letterpress cleaning, friction dry clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com