Method and device for acquiring optimal parameters of photoetching machine

A technology of optimal parameters and lithography machine, applied in the direction of photolithography exposure device, micro-lithography exposure equipment, etc., can solve the problems of increasing the complexity of lithography machine and the impact of the service life of silicon wafers, and achieves a wide range of applications, Strong versatility and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

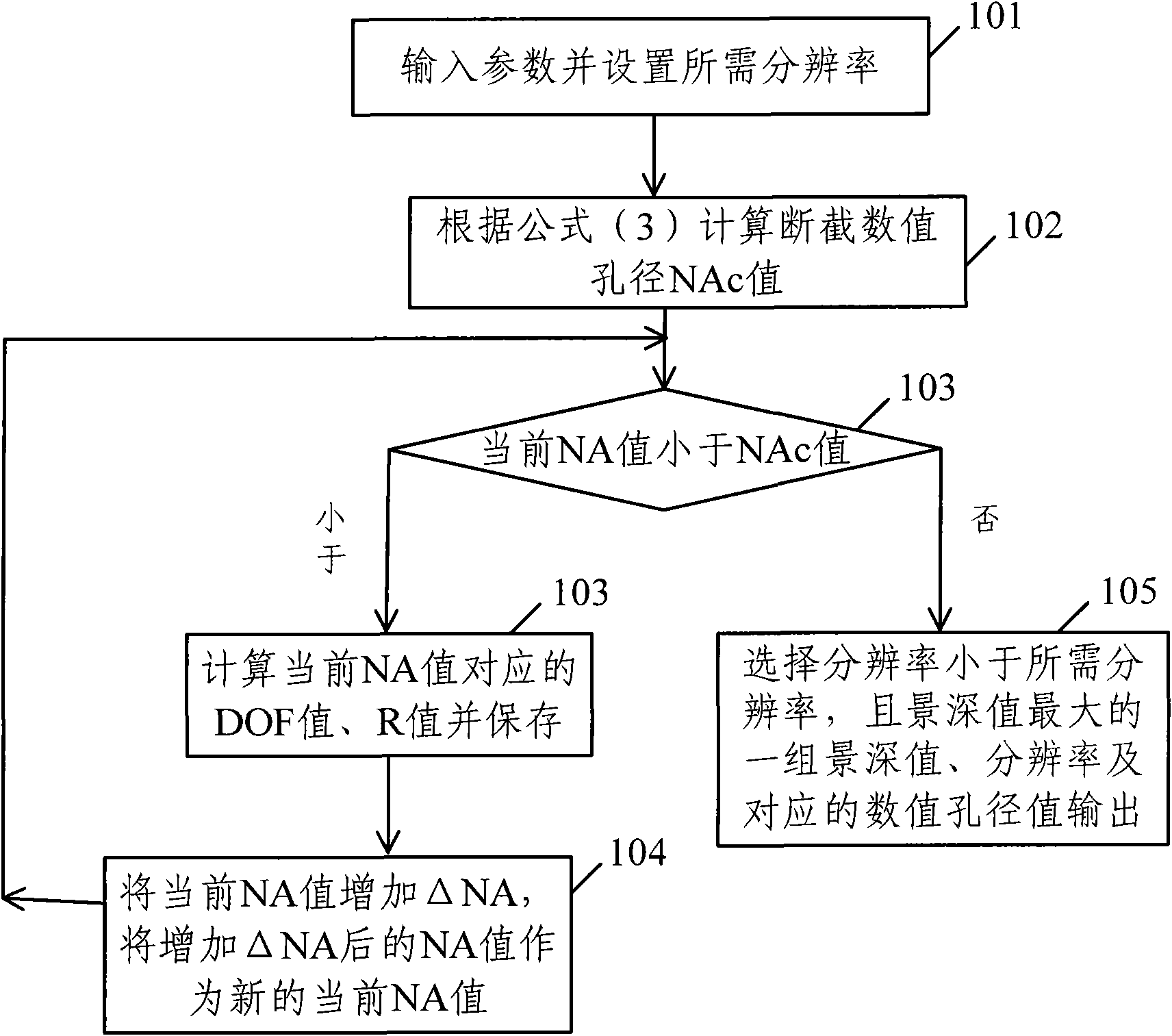

[0036] The basic idea of the present invention is: based on the NA value, gradually calculate the resolution and depth of field corresponding to each NA value from the initial NA value to the truncated numerical aperture NAc value, and select and output the best one according to the required resolution. A set of parameters is given to the user; furthermore, according to the output parameters, the adjustment effect of the lithography machine can be simulated, which can reduce the trial marking of silicon wafers and save costs.

[0037] Below in conjunction with accompanying drawing, concrete method of the present invention is realized and further described, as image 3 As shown, the method includes:

[0038] Step 101, input parameters and set required resolution.

[0039] Here, the input parameters include the wavelength λ of the exposure light source, the photoresist constant K 1 , photoresist constant K 2 , initial NA value and NA value increasing step size ΔNA.

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com