Molding method of components of heterogeneous materials

A multi-phase material and molding method technology, applied in ceramic molding machines, program control, instruments, etc., can solve the problems of inability to shape a variety of complex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

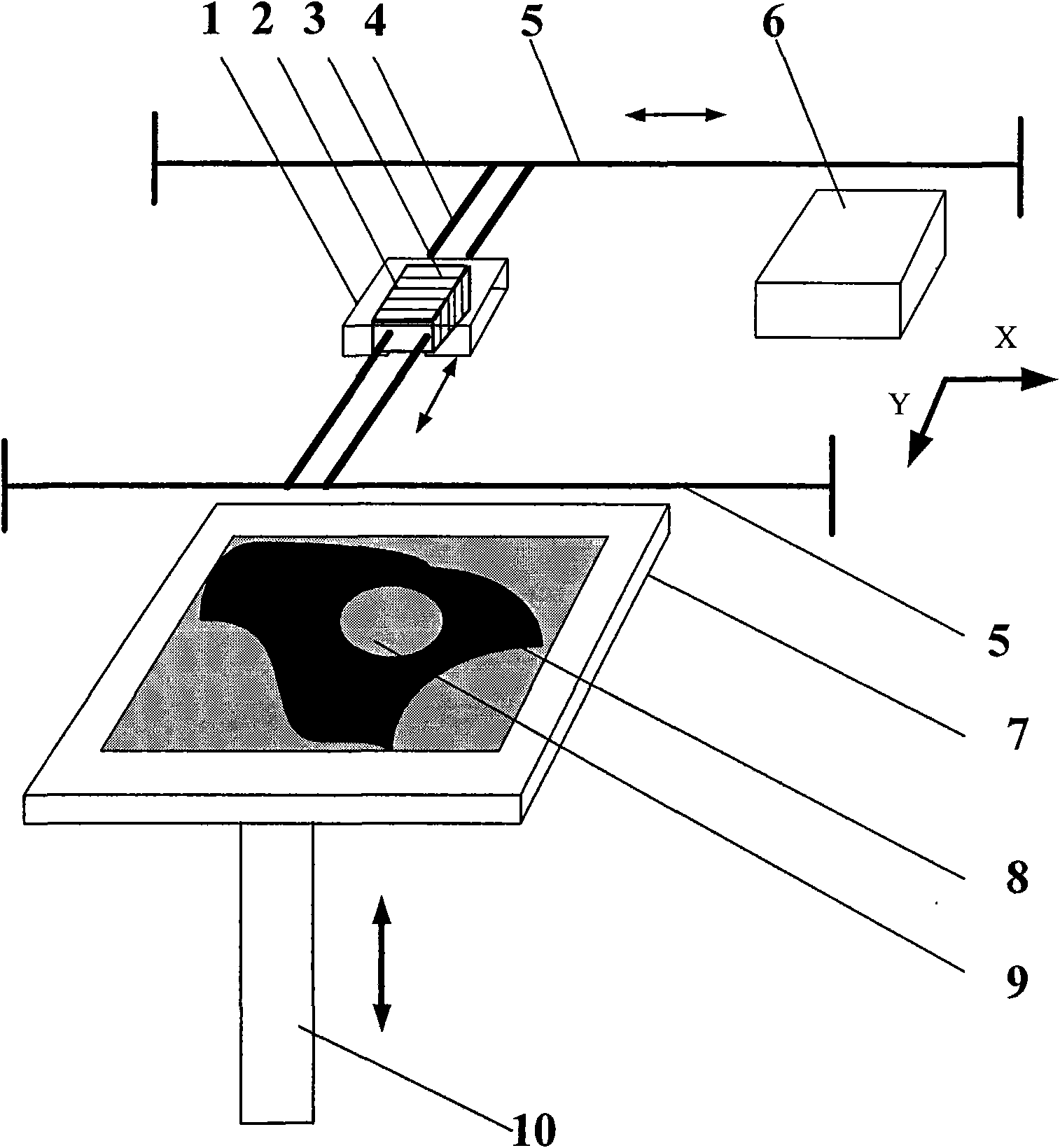

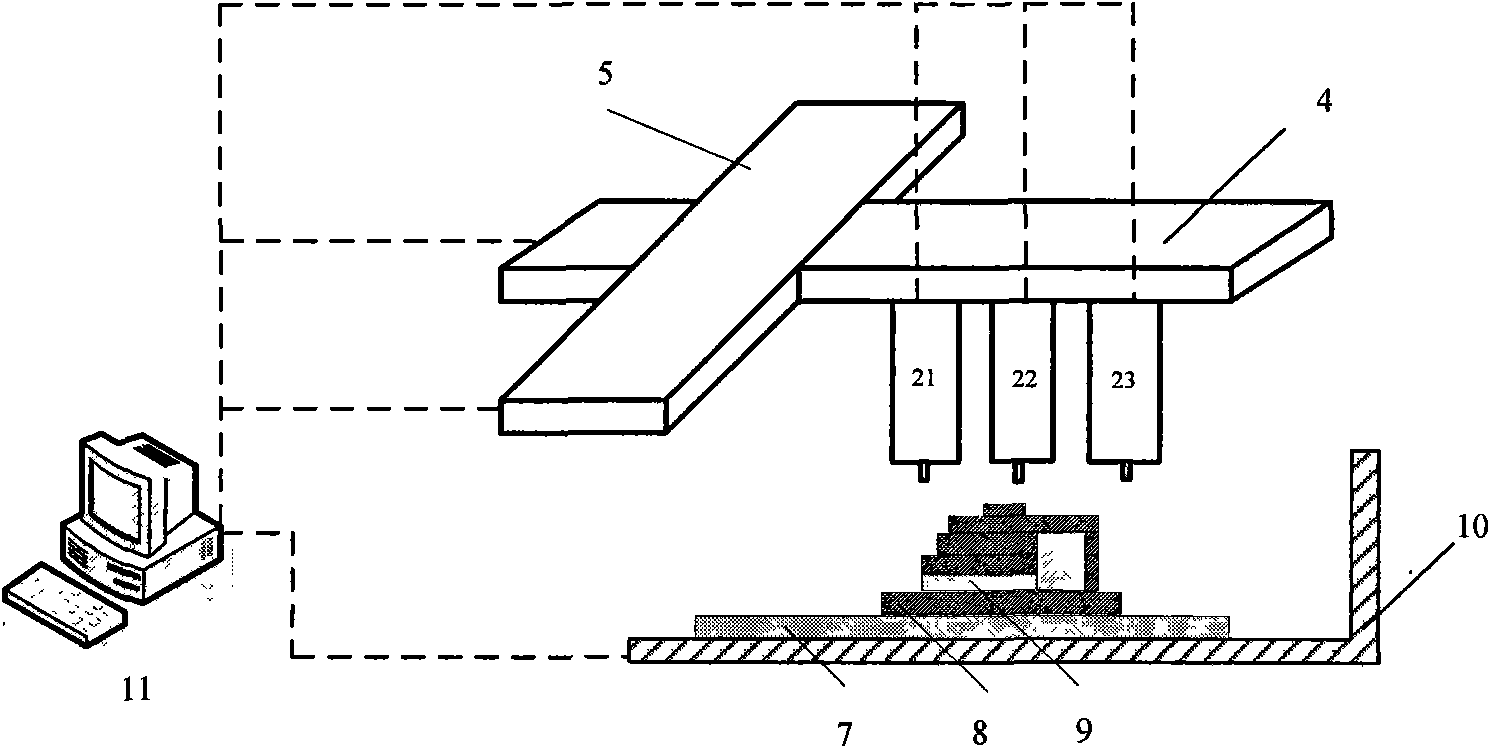

[0066] Such as figure 1 , figure 2 As shown, the specific process of making multiphase material parts layer by layer by droplet jetting is as follows:

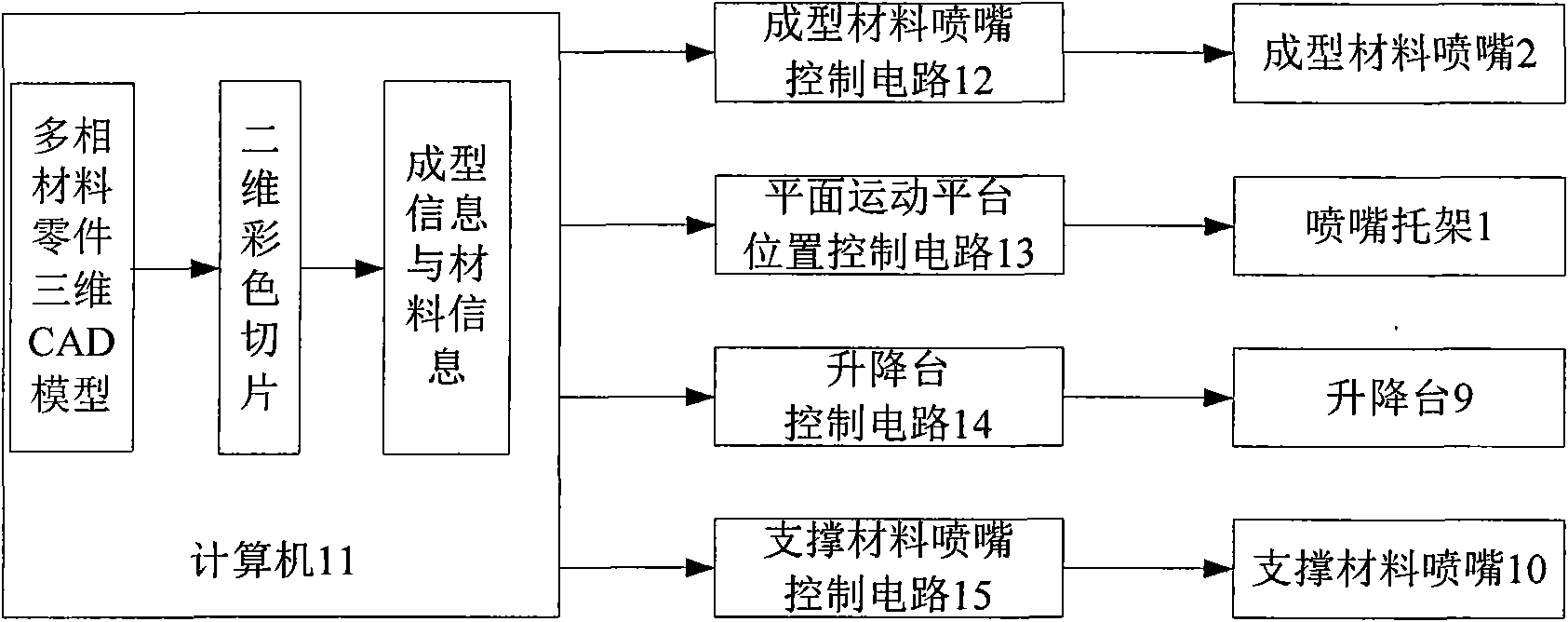

[0067] The 3D CAD model of the 3D structure to be processed is designed by a computer with high-speed computing capabilities. According to the functional requirements of the part, the material design of the 3D CAD model is carried out, that is, the material is represented by color, and then the CAD entity slice is divided into three parts. layer, forming a series of two-dimensional slices containing structural information and material information. The thickness of each slice can be the same or different, and the thickness of each slice is 1 μm-300 μm. The computer 11 controls each mechanism to perform coordinated movements according to the forming information of each layer. Specifically, when the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com