Square lithium ion battery terminal post anti-rotation device

A lithium-ion battery, anti-rotation technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of increased pole mass, difficult assembly, and high cost, and achieves prevention of pole rotation, simple structure, and assembly. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

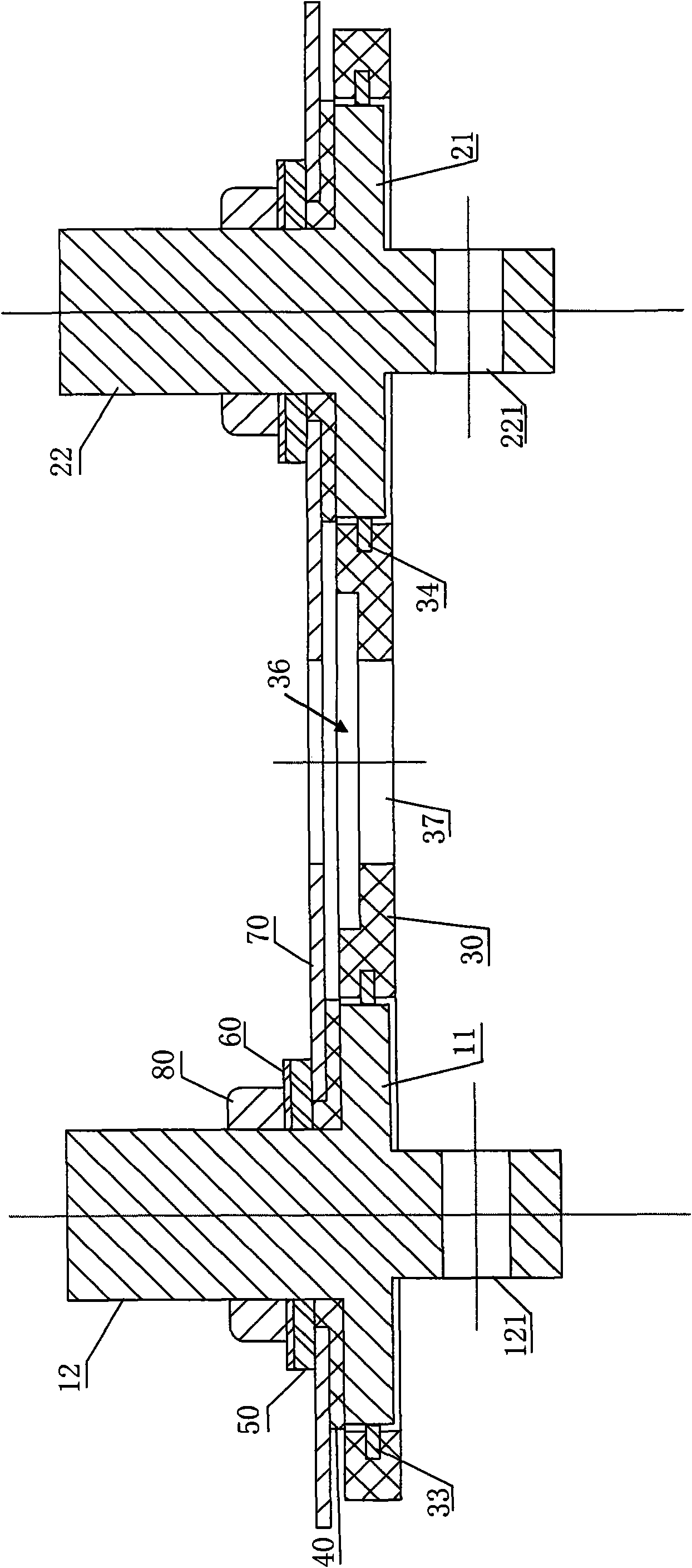

[0014] An anti-rotation device for a square lithium-ion battery pole, comprising positive and negative poles 10, 20 composed of positive and negative pole bodies 12, 22 and positive and negative pole stands 11, 21 respectively, positive and negative pole stands 11, 21 and positive 1. The negative pole body 12 and 22 are integrally formed during processing. The positive and negative column bodies 12, 22 are composed of upper parts 12a, 22a, and lower parts 12b, 22b respectively, and flat platform-shaped positive and negative poles are arranged between the upper parts 12a, 22a, lower parts 12b, 22b of the positive and negative column bodies 12, 22 Platforms 11, 21, the present invention also includes a support 30 that is inlaid with the positive and negative poles 10, 20, and the support 30 is provided with the first and second through holes that match the peripheral contours of the positive and negative poles 11, 21 respectively 31, 32, the peripheral contours of the positive a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com