Method for recycling sludge in coal washery and online direct recycling process

A technology for coal slime recovery and coal washing plant, applied in dehydration/drying/concentrated sludge treatment, solid waste removal and other directions, can solve the problems of inconvenient storage, loading and unloading, high viscosity and high water content, and achieves the goal of overcoming stickiness and good looseness. Effects of Sex and Mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

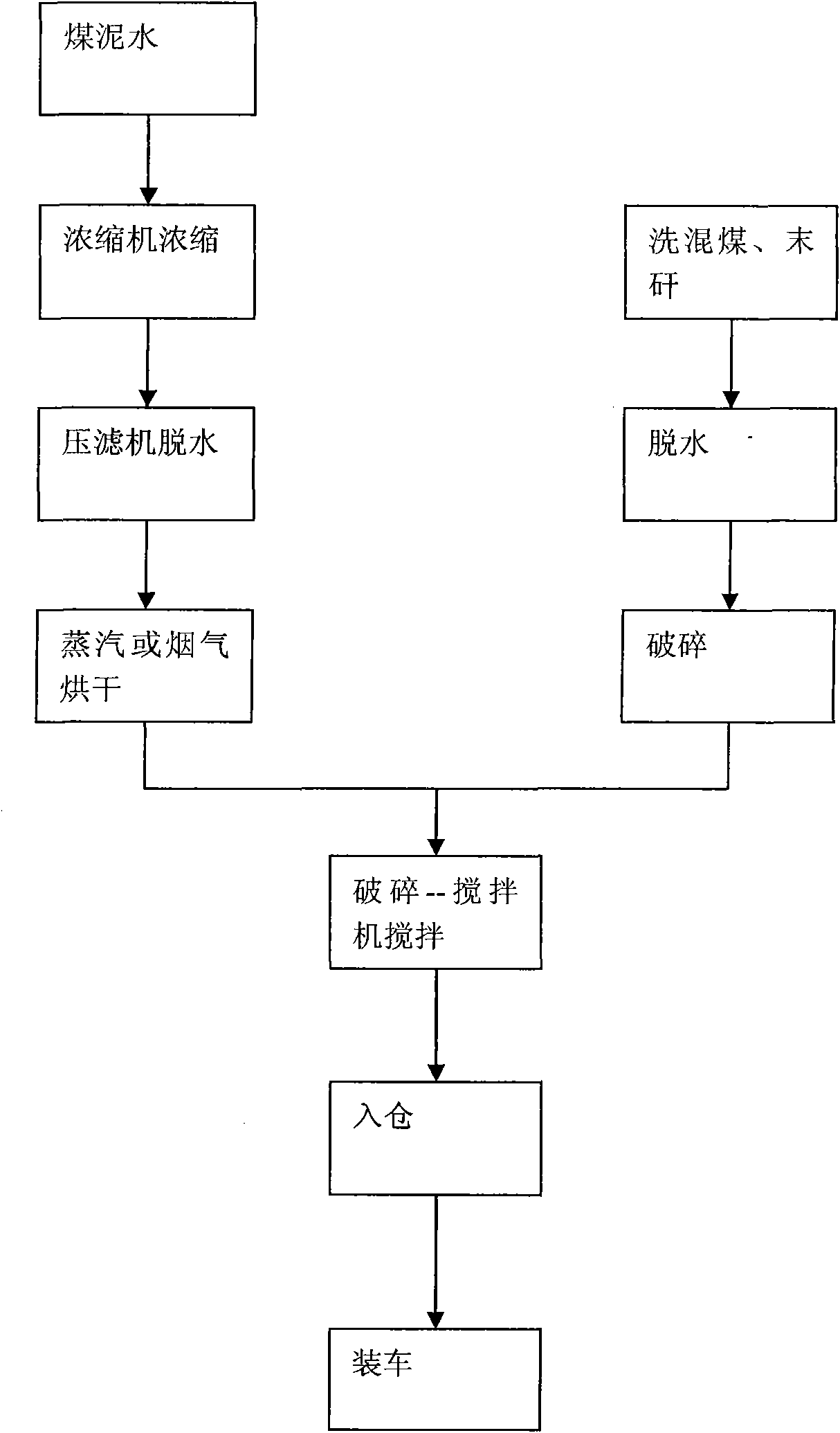

[0014] Such as figure 1 As shown, in this online direct recovery process, the coal slime is first dried and then mixed with loose aggregate.

[0015] One is the slime line: the slime water is concentrated by the concentrator, the bottom of the concentrator flows through the filter press for dehydration, and the dehydrated coal slime is dried by a steam dryer, and the moisture is controlled below 15-18%; the second is to wash and mix coal 3. End gangue line: use a crusher to crush the washed mixed coal and the last gangue to make it less than 10mm, and the expected moisture content is less than 6%; Merge in proportion, use the "coal slime recovery continuous crushing mixer" to stir the coal slime, washed coal, and waste gangue to form a coal slime-washed coal mixture, a part of the water in the slime is absorbed by the washed coal, and the overall moisture is controlled at 13 % or less, it can be put into the warehouse directly and transported out by train or car like ordinary...

Embodiment 2

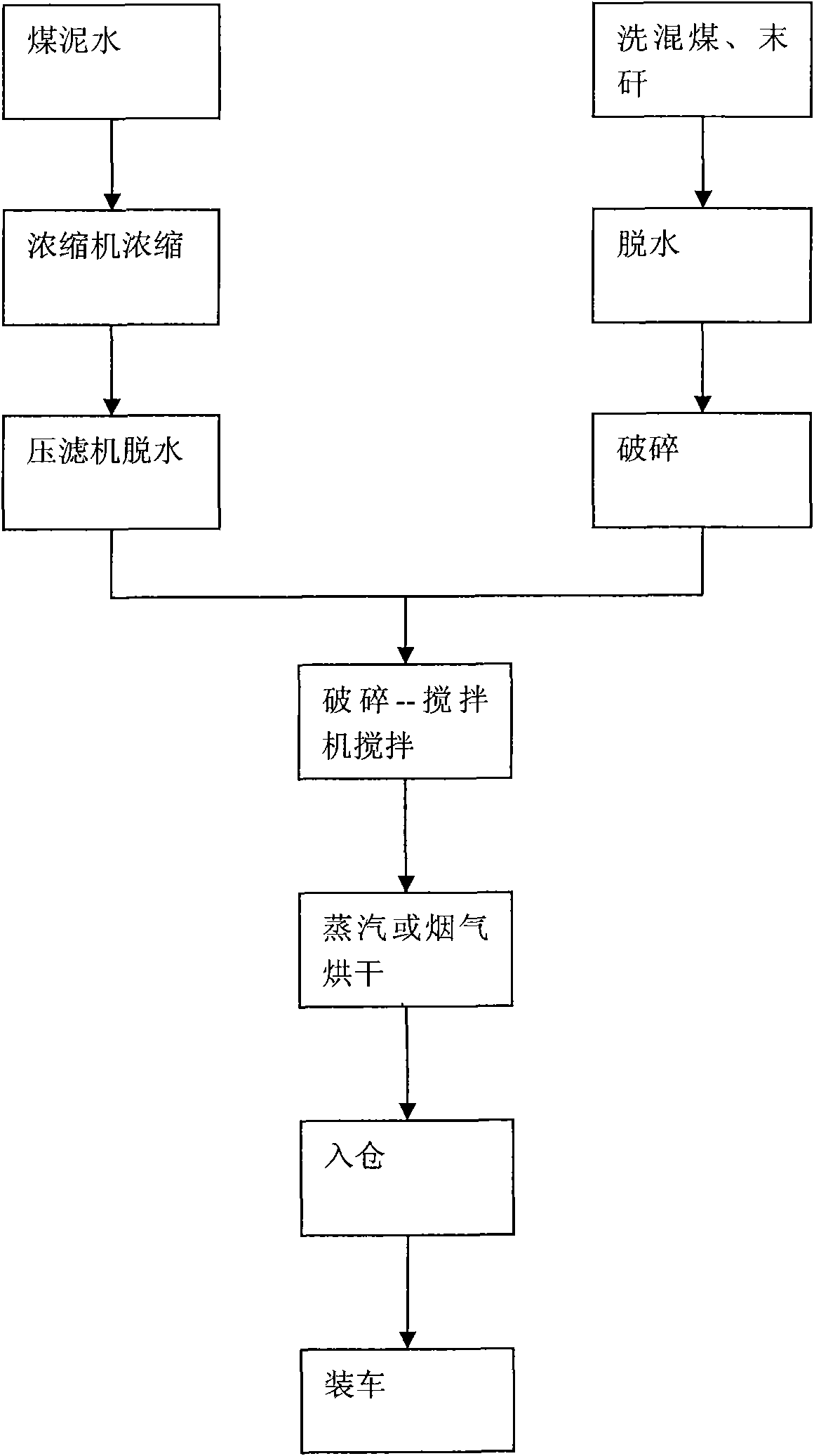

[0018] Such as figure 2 As shown, in this online direct recovery process, the coal slime is first mixed with loose aggregate and then dried.

[0019] One is the slime line: the slime water is concentrated by the concentrator, the bottom of the concentrator flows through the filter press for dehydration, the water content is controlled at 20-23%, and the dehydrated coal slime is waiting to be stirred; Crushing the washed mixed coal and the last gangue to make it less than 10mm, and the expected moisture content is below 6%; the coal slime of the coal slime line and the washed mixed coal and the last gangue of the washed coal line are combined in proportion, and the "coal slime Recycling continuous crushing mixer "stirs coal slime, washed coal, and waste gangue to form a coal slime-washed coal mixture. Part of the water in the slime is absorbed by the washed coal, and then dried by steam or flue gas dryer. The moisture content is controlled below 13%, and the product can be di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com