Process and device for forming straight-edge conical cylinder forged piece of nuclear power evaporator

A nuclear power evaporator and conical cylinder technology, applied in the field of forging, can solve problems such as difficulty in forming forgings with straight edge conical cylinders, and achieve the effects of reducing research costs, machining allowances, and design time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

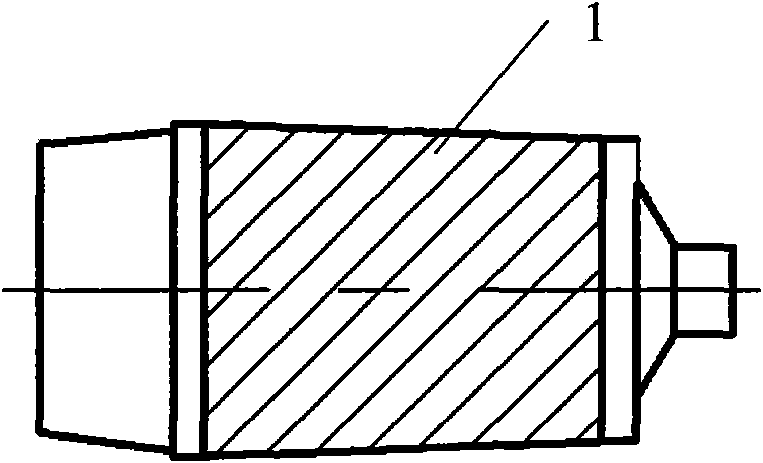

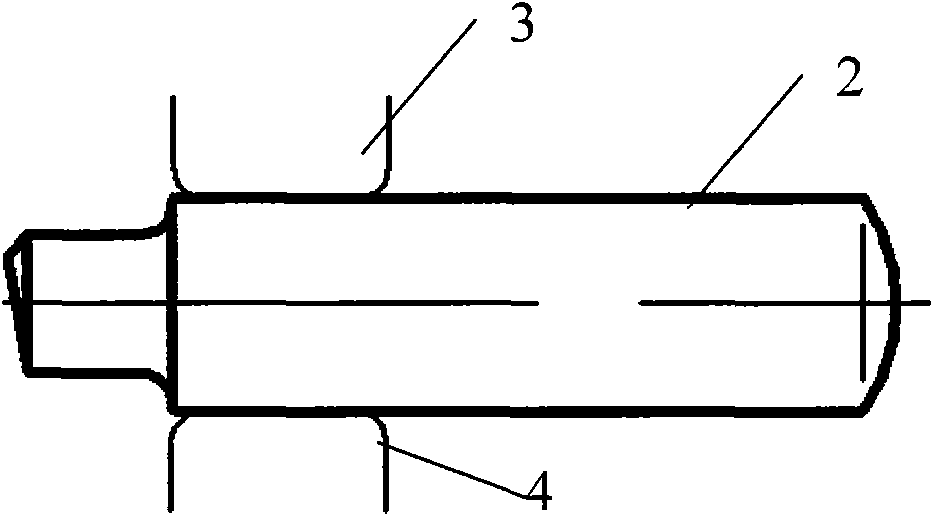

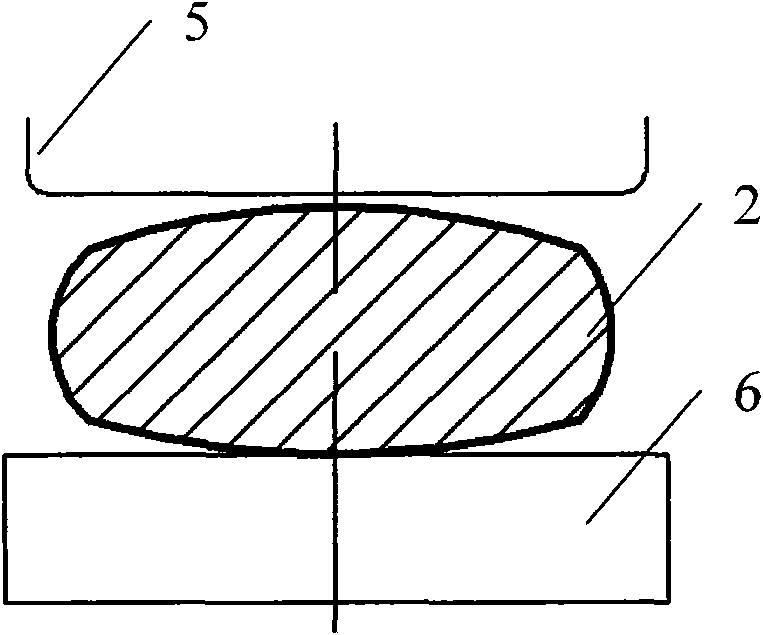

[0060] The forged part in this embodiment is a pilot test forging of a certain type of nuclear power evaporator conical cylinder. The pressing speed of the upper anvil of the hydraulic press is about 20mm / s. The finite element simulation results of the hole reaming process are shown in Figure 4a -d, Figure 5 For the comparison between the formed forging (grid line part) and the processed part (contour line part), the inner diameter of the large end of the formed forging is 815mm, the outer diameter is 1000mm, the wall thickness is 185mm, the height is 1350mm, and the taper is 11.1°. It can be seen from the figure that the machining allowance of the entire forging is uniform, and the dimensions of each part meet the processing requirements of the part.

[0061] The results of the examples show that the present invention has designed a nuclear power evaporator band straight-edge conical cylinder forging forming process and forming device, and adopts finite element simulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com