Manual shaver

A razor and blade technology, applied in the field of manual razors, can solve the problems of low shaving efficiency, inability to make full use of blades, wasting blades, etc., and achieve the effects of improving shaving efficiency, improving utilization rate, and saving blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

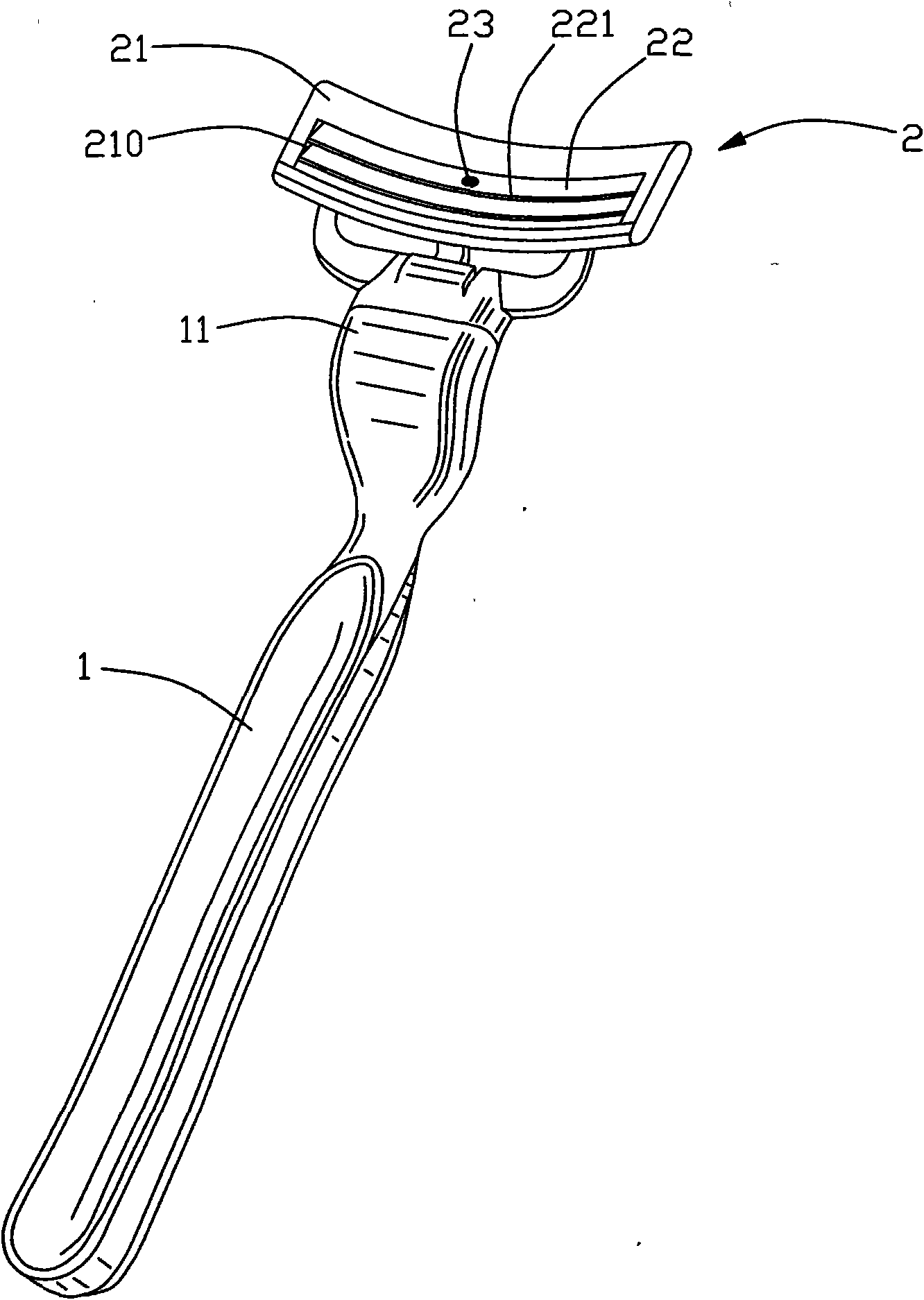

[0020] A manual shaver, cf. figure 1 , including a handle 1 and a blade assembly 2 mounted on the head 11 of the handle 1 , the blade assembly 2 includes a blade holder 21 and a blade 22 installed in the blade holder 21 . The blade holder 21 is a rigid body, curved as a whole, and has a curved fitting groove 210 on its concave surface; the blade 22 is planar and elastic before being assembled with the blade holder 21, and the blade 22 is assembled in the fitting groove Elastic deformation occurs after the 210 is centered, forming a curved shape suitable for the fitting groove 210, and the blade 221 is also curved. The blade 22 is connected to the assembly groove 210 through a screw 23 , and the curvature of the blade 22 can be adjusted by adjusting the screw 23 .

Embodiment 2

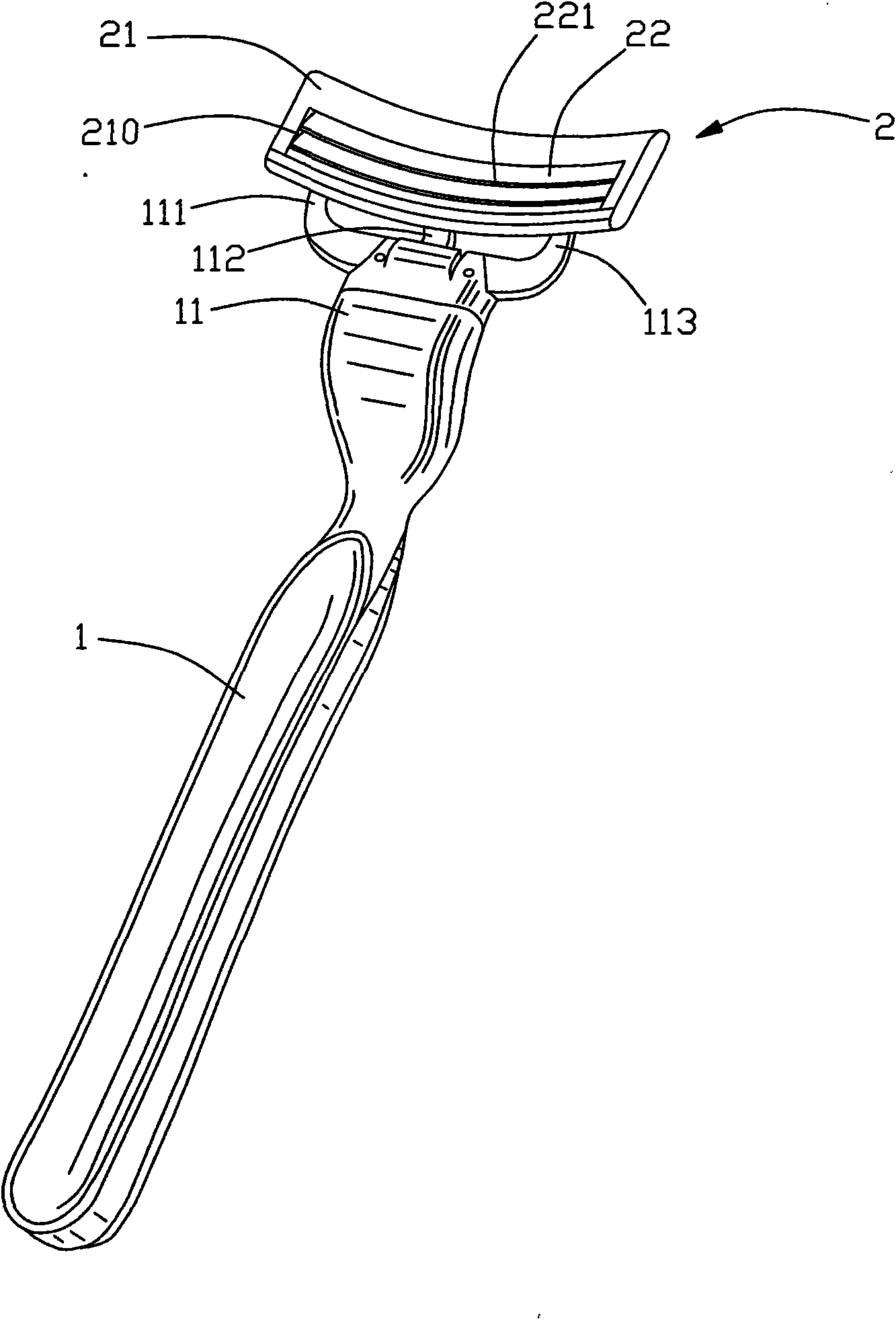

[0022] A manual shaver, cf. figure 2 , including a handle 1 and a blade assembly 2 installed on the head 11 of the handle 1, the blade assembly 2 includes a blade holder 21 and a blade 22 installed in the blade holder 21, the blade holder 21 is provided with an assembly groove 210, and the blade 22 is assembled in the fitting groove 210 . Both the blade holder 21 and the blade 22 are elastic, and the blade holder 21 and the blade 22 are straight before they are assembled with the head 11 of the handle 1 .

[0023] The head 11 of the handle 1 has three connecting buckles 111, 112 and 113, the three connecting buckles 111, 112 and 113 are located on a curve, the blade holder 21 has at least three corresponding buckle grooves, the blade The frame 21 is connected with the head 11 of the handle 1 through one-to-one corresponding buckling of the three buckle grooves and the three connecting buckles 111, 112 and 113. Elastically deformed into a curved shape, the blade 22 is bent t...

Embodiment 3

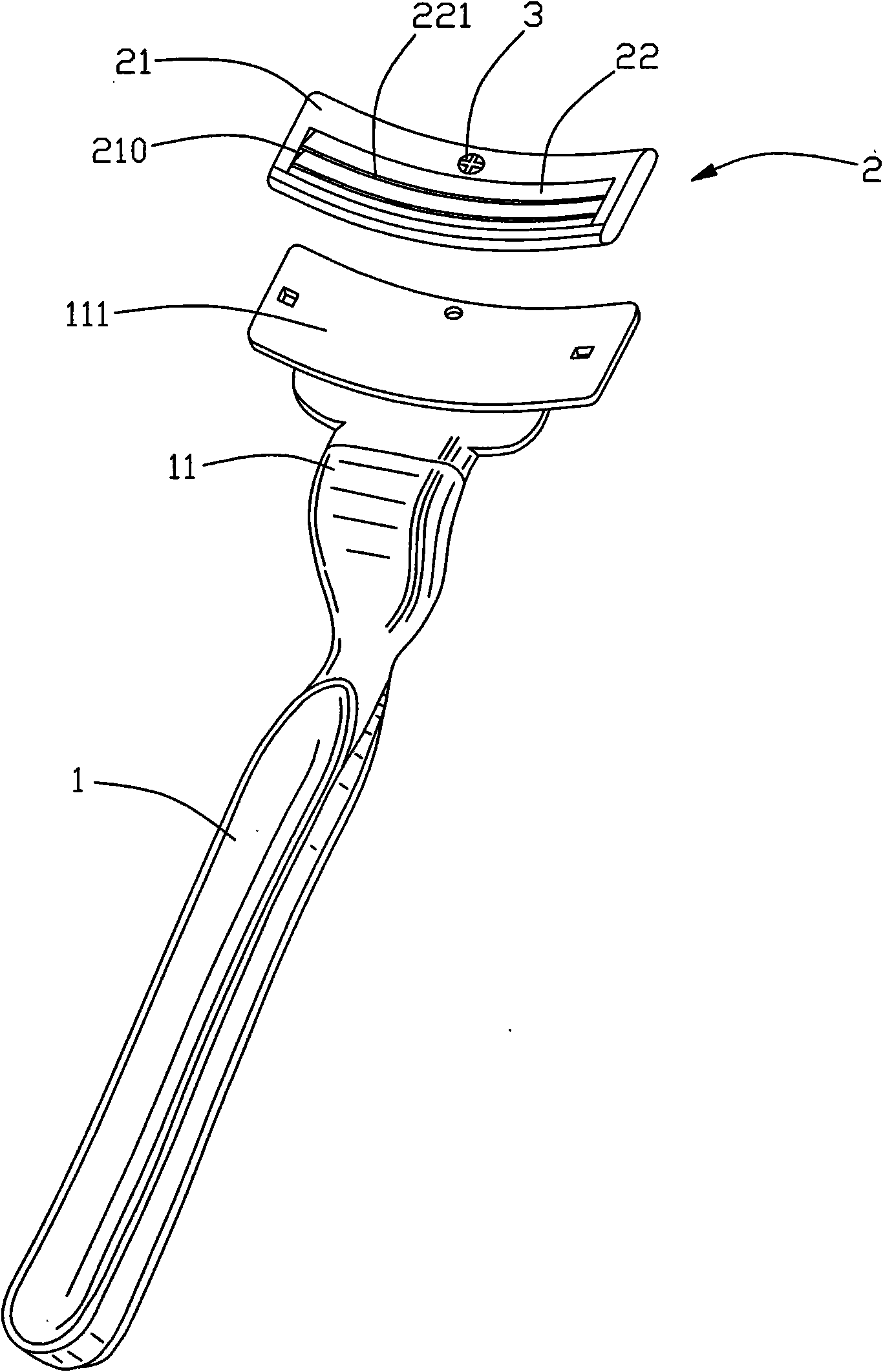

[0026] A manual shaver, cf. image 3 , including a handle 1 and a blade assembly 2 installed on the head 11 of the handle 1, the blade assembly 2 includes a blade holder 21 and a blade 22 installed in the blade holder 21, the blade holder 21 is provided with an assembly groove 210, and the blade 22 is assembled in the fitting groove 210 . Both the blade holder 21 and the blade 22 are elastic, and the blade holder 21 and the blade 22 are straight before they are assembled with the head 11 of the handle 1 .

[0027] The head 11 of the handle 1 has a concave curved mounting surface 111, the blade frame 21 is assembled on the mounting surface 111 by the screw 3, the blade frame 21 is elastically deformed after being assembled with the mounting surface 111, and forms a shape corresponding to the mounting surface 111. The fitting surface 111 is in a suitable curved shape, the blade 22 is bent together with the blade holder 21 , and its blade 221 is also curved accordingly. The cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com