Inflatable vibration damper

A shock absorber and gas-filled technology, applied in gas shock absorbers, shock absorbers, shock absorbers, etc., can solve problems such as differences in actual use environments, tedious theoretical calculations, and different requirements for shock absorbers, and reach the scope of use The effect of wide, wide application field and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawings and examples.

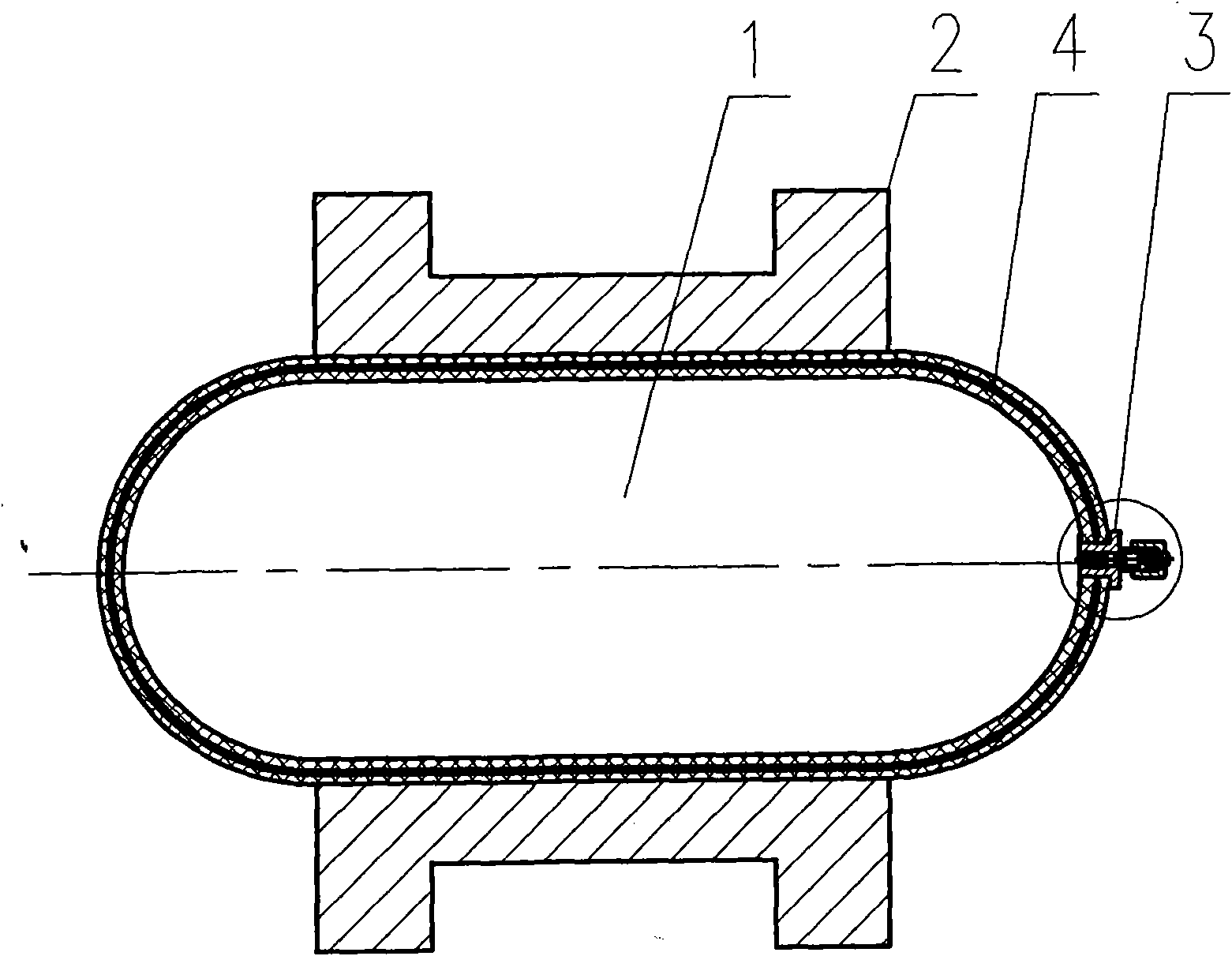

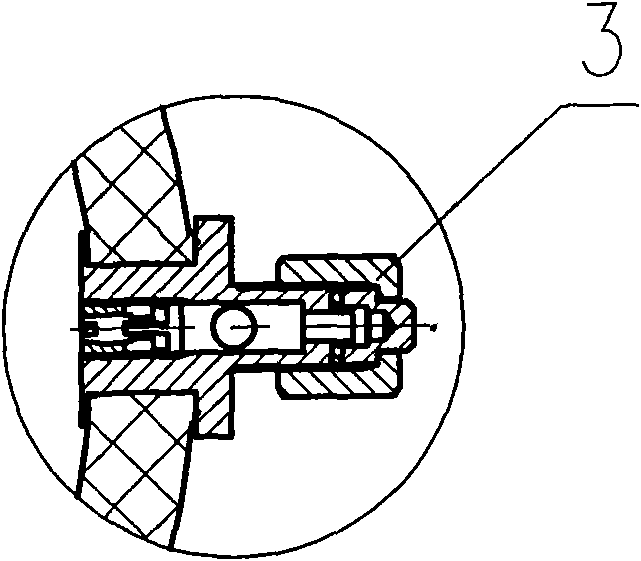

[0015] like figure 1 As shown, an inflatable shock absorber is composed of an inflatable rubber bag 1, a metal mounting part 2 and an inflation nozzle assembly 3. The inflatable rubber bag 1 vulcanizes the installation part 2 and the inflation nozzle assembly 3 into one body through a vulcanization process. , The shape of the mounting piece matches the vibration-reducing instrument. According to different use environments and working conditions, the inflatable rubber bag 1 can be made of polyurethane synthetic rubber material with high elasticity, high elongation and strong pyrolysis resistance. In order to ensure the pressure resistance and Tensile strength, in the bag making process, is designed with interlining layer 4, and its function is to prevent the bag from being damaged when the gas pressure increases and the bag expands to deform.

[0016] Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com