Method for testing defects of single membrane electrode assembly in fuel cell stack

A fuel cell stack and membrane electrode group technology, applied in the direction of material resistance, etc., can solve the problems of fuel cell stack operation impact and difficult detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

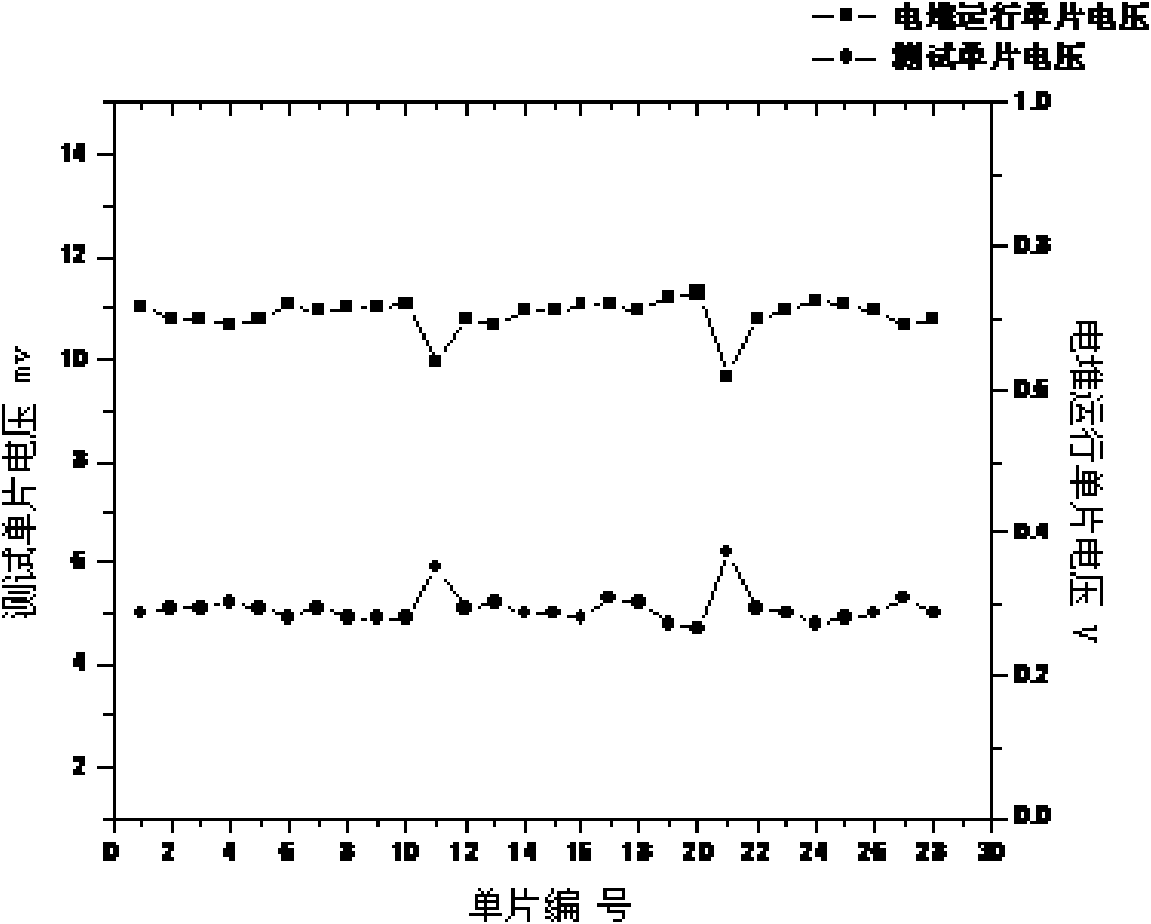

Embodiment 1

[0019] Connect the two electrodes of the constant current source to the positive and negative poles of the fuel cell stack, and fix the single-chip acquisition fixture of the voltage detection system on the fuel cell stack. The temperature of the fuel cell stack is controlled at 60°C. Inject saturated and humidified hydrogen gas at a flow rate of 0.1L / min, adjust the current of the constant current source to 1A after 10 minutes, and collect the voltage values of 28 membrane electrode groups after 4 minutes, respectively in V 1 , V 2 、···V 28 , and the results are shown in Table 1.

[0020] Table 1 Voltage values of each membrane electrode group (in mV)

[0021] V 1

V 2

V 3

V 4

V 5

V 6

V 7

V 8

V 9

V 10

V 11

V 12

V 13

V 14

5

5.1

5.1

5.2

5.1

4.9

5.1

5.0

5.0

5.0

5.8

5.2

5.2

5.1

V...

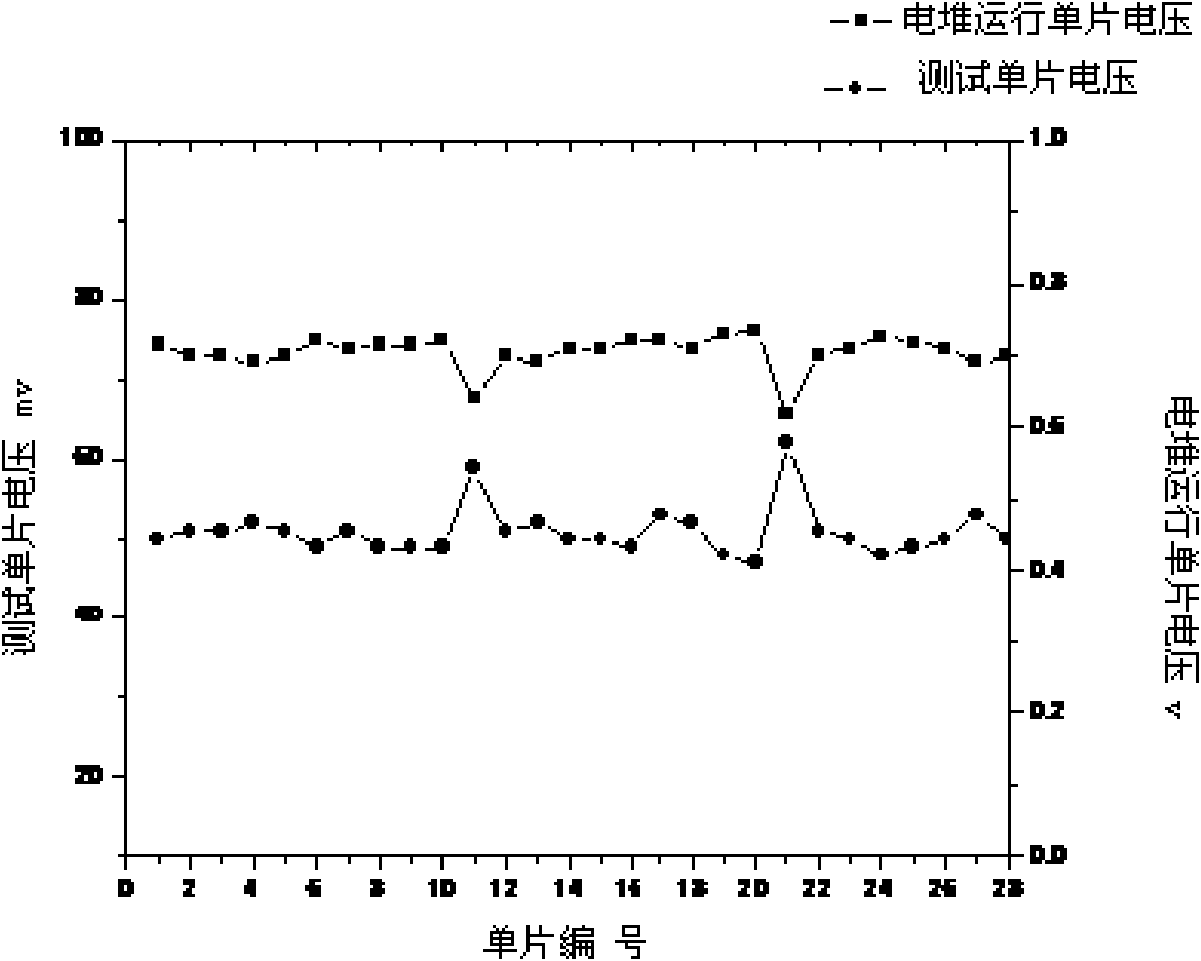

Embodiment 2

[0028] Connect the two electrodes of the constant current source to the positive and negative poles of the fuel cell stack, and fix the single-chip acquisition fixture of the voltage detection system on the fuel cell stack. The temperature of the fuel cell stack is controlled at 65°C. On both sides of the fuel cell MEA Inject saturated and humidified hydrogen gas at a flow rate of 10 L / min, adjust the current of the constant current source to 10 A after 20 minutes, and collect the voltage values of 28 membrane electrode groups after 10 minutes, respectively expressed as V 1 -V 28 , and the results are shown in Table 2.

[0029] Table 2 Voltage values of each membrane electrode group (in mV)

[0030] V 1

V 2

V 3

V 4

V 5

V 6

V 7

V 8

V 9

V 10

V 11

V 12

V 13

V 14

50

51

51

52

51

49

51

50

50

50

58

52

52

51

V 15...

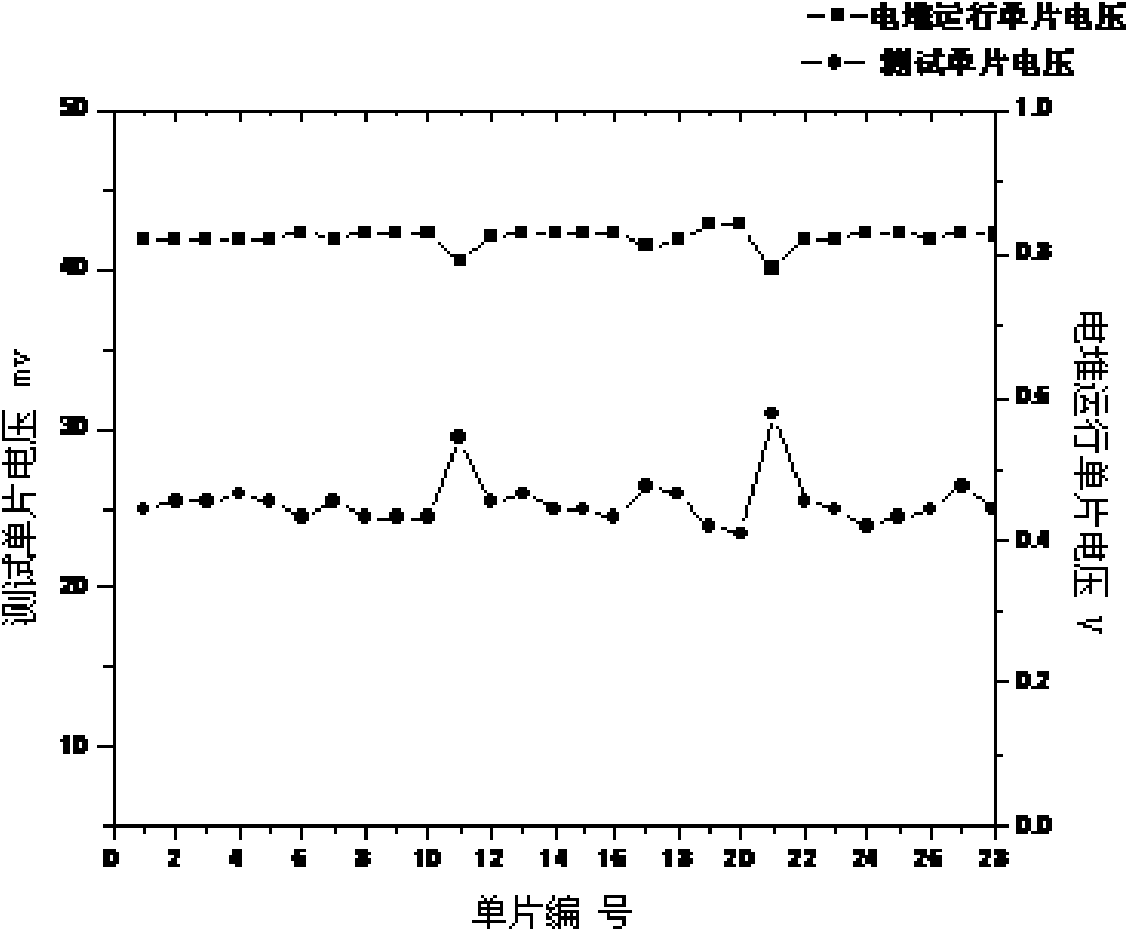

Embodiment 3

[0036] Connect the two electrodes of the constant current source to the positive and negative poles of the fuel cell stack, and fix the monolithic acquisition fixture of the voltage detection system on the fuel cell stack. The temperature of the fuel cell stack is controlled at 75°C. Inject saturated and humidified hydrogen gas at a flow rate of 5L / min, adjust the current of the constant current source to 5A after 15 minutes, and collect the voltage values of 28 membrane electrode groups after 8 minutes, respectively in V 1-V 28 , and the results are shown in Table 3.

[0037] Table 3 Voltage values of each membrane electrode group (in mV)

[0038] V 1

V 2

V 3

V 4

V 5

V 6

V 7

V 8

V 9

V 10

V 11

V 12

V 13

V 14

25

25.5

25.6

26

25.5

24.8

25.6

25.1

25

25.1

29.1

26

26

25.5

V 15

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com