Fixing piece and heat dissipating device using same

一种散热装置、固定件的技术,应用在半导体/固态器件零部件、锁紧紧固件、螺纹紧固件等方向,能够解决生锈、操作繁琐、脱落杆件等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

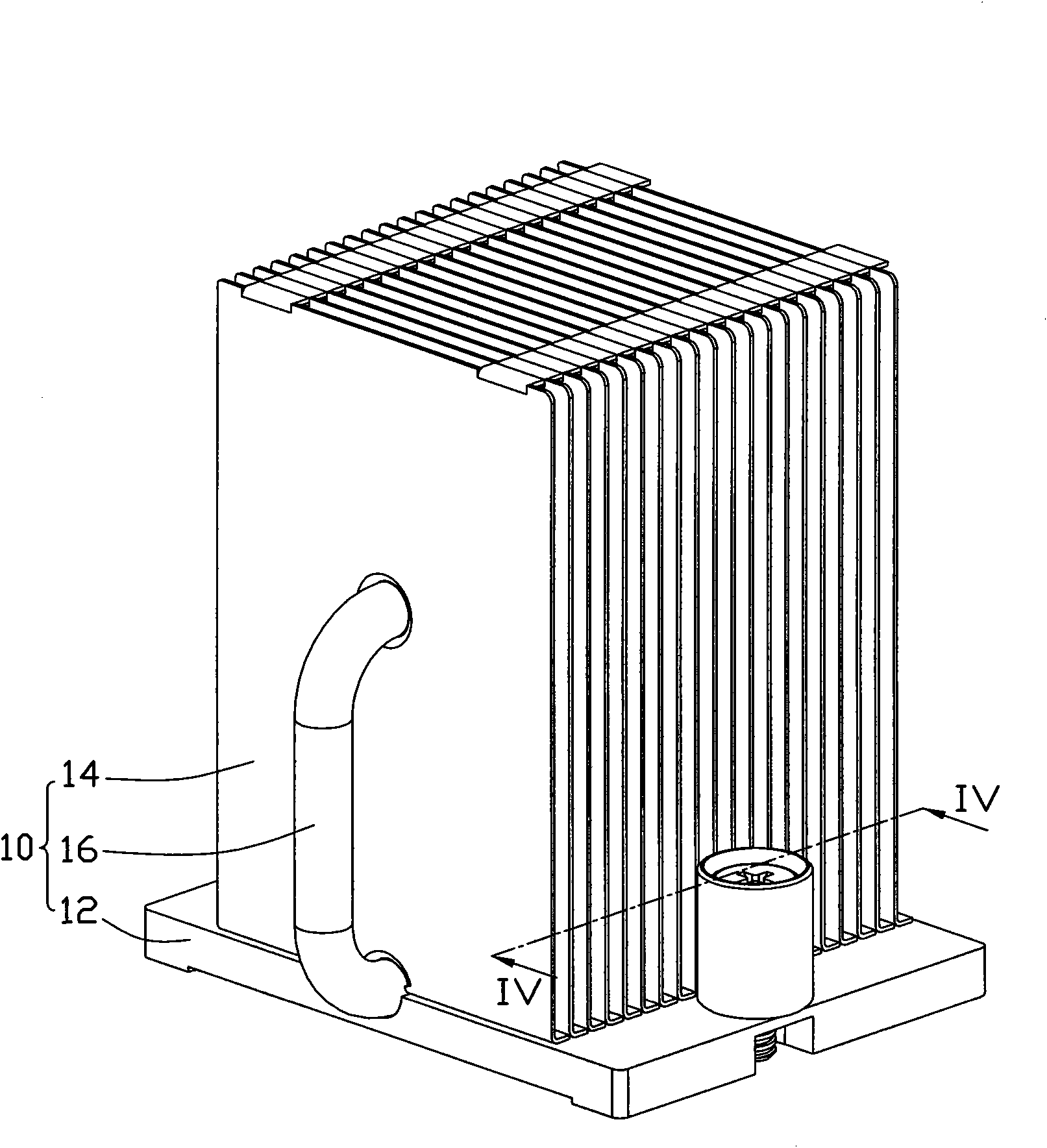

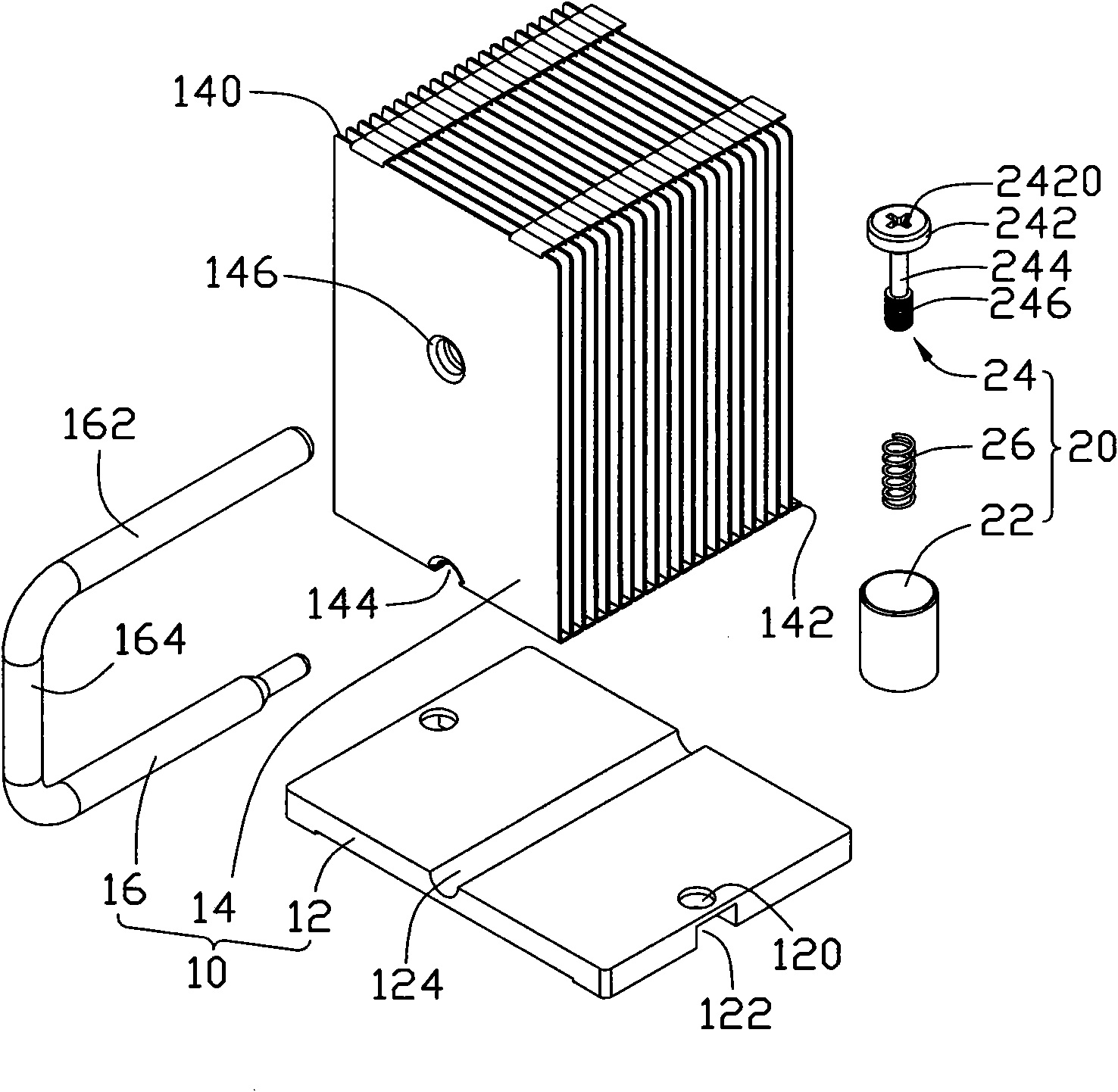

[0013] see figure 1 , a heat dissipation device according to a preferred embodiment of the present invention is used for dissipating heat from a heat-generating electronic component (not shown) mounted on a circuit board (not shown). The heat dissipation device includes a heat sink 10 and several fixing pieces 20 for fixing the heat sink 10 on the electronic components.

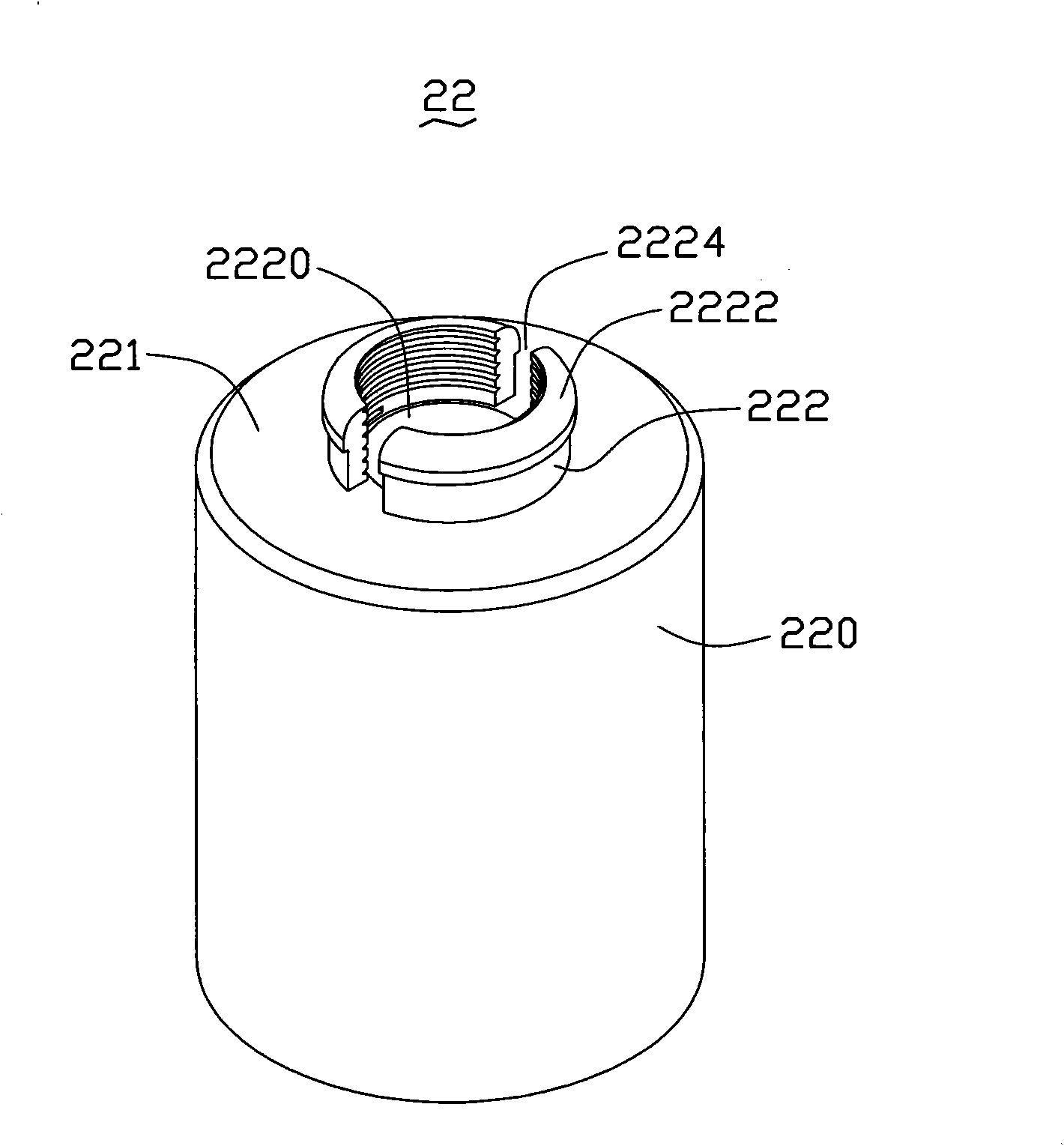

[0014] Please also refer to figure 2 The heat sink 10 includes a bottom plate 12 , a heat sink set 14 arranged on the bottom plate 12 , and a heat pipe 16 connecting the bottom plate 12 and the heat sink set 14 through further heat conduction. The bottom plate 12 is roughly a rectangular flat body, the bottom of which is in contact with the electronic components. The base plate 12 is provided with a perforation 120 penetrating up and down in the middle of the two sides, and a depression 122 is formed at the bottom of the base plate 12 corresponding to the perforation 120, so that the thickness of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com