Polyacetal resin composition and molded article thereof

A technology of polyacetal resin and polyacetal copolymer, which is applied in the field of polyacetal resin composition, can solve the problem of reducing formaldehyde, etc., and achieve the effect of reducing the amount of formaldehyde generated and inhibiting oozing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

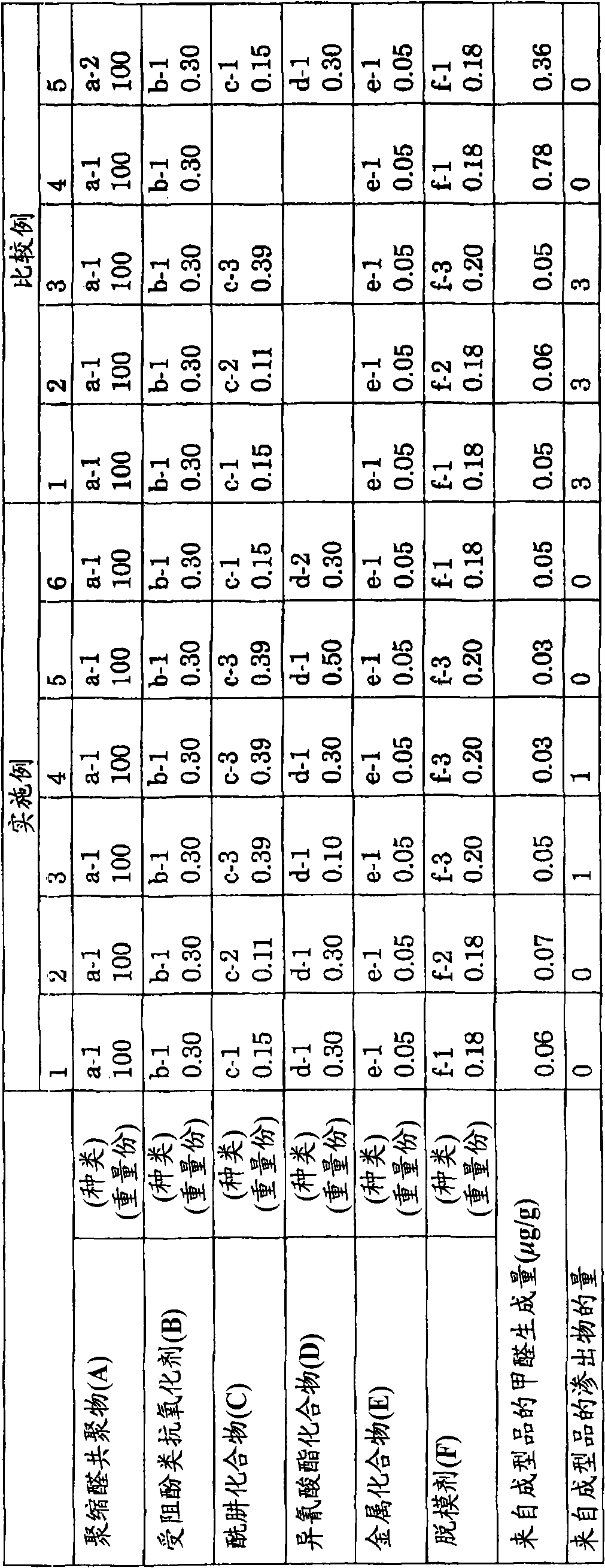

Examples

preparation example Construction

[0080] The method for preparing the polyacetal resin composition of the present invention is not particularly limited, and it can be prepared by various conventionally known methods as a method for preparing a resin composition. For example, (1) a method of mixing all the components constituting the composition, supplying it to an extruder, and melting and kneading to obtain a granular composition; (2) extruding a part of the components constituting the composition The method of supplying from the main feeding port, supplying the remaining ingredients from the side feeding port, and melting and kneading to obtain a granular composition; (3) by extrusion, etc., firstly preparing granules with different compositions, and then mixing the granules, A method of adjusting to a predetermined composition, etc.

[0081] In the preparation of the composition using an extruder, it is preferable to use an extruder having one or more devolatilization vents, and it is more preferable to use...

Embodiment 1-6

[0101] According to the composition shown in Table 1, blend hindered phenolic antioxidant (B), formaldehyde trapping agent (hydrazide compound) (C), isocyanate compound (D) and other compounds in polyacetal copolymer (A), use A 30mm twin-screw extruder is used for melt mixing to make a granular composition. Next, using an injection molding machine, the pellets were molded into test pieces under the above-mentioned molding condition (1), and the amount of formaldehyde generated from the molded product was measured. Exudation from molded articles was also observed. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com