Method for designing equipment removing oxide skin on surface of slab band

A design method and oxide skin technology, which are applied in workpiece surface treatment equipment, chemical instruments and methods, and cleaning methods using tools, etc., can solve the problems of unclean cleaning, pitting, affecting product quality, etc., and achieve compact structure design, Improved surface quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

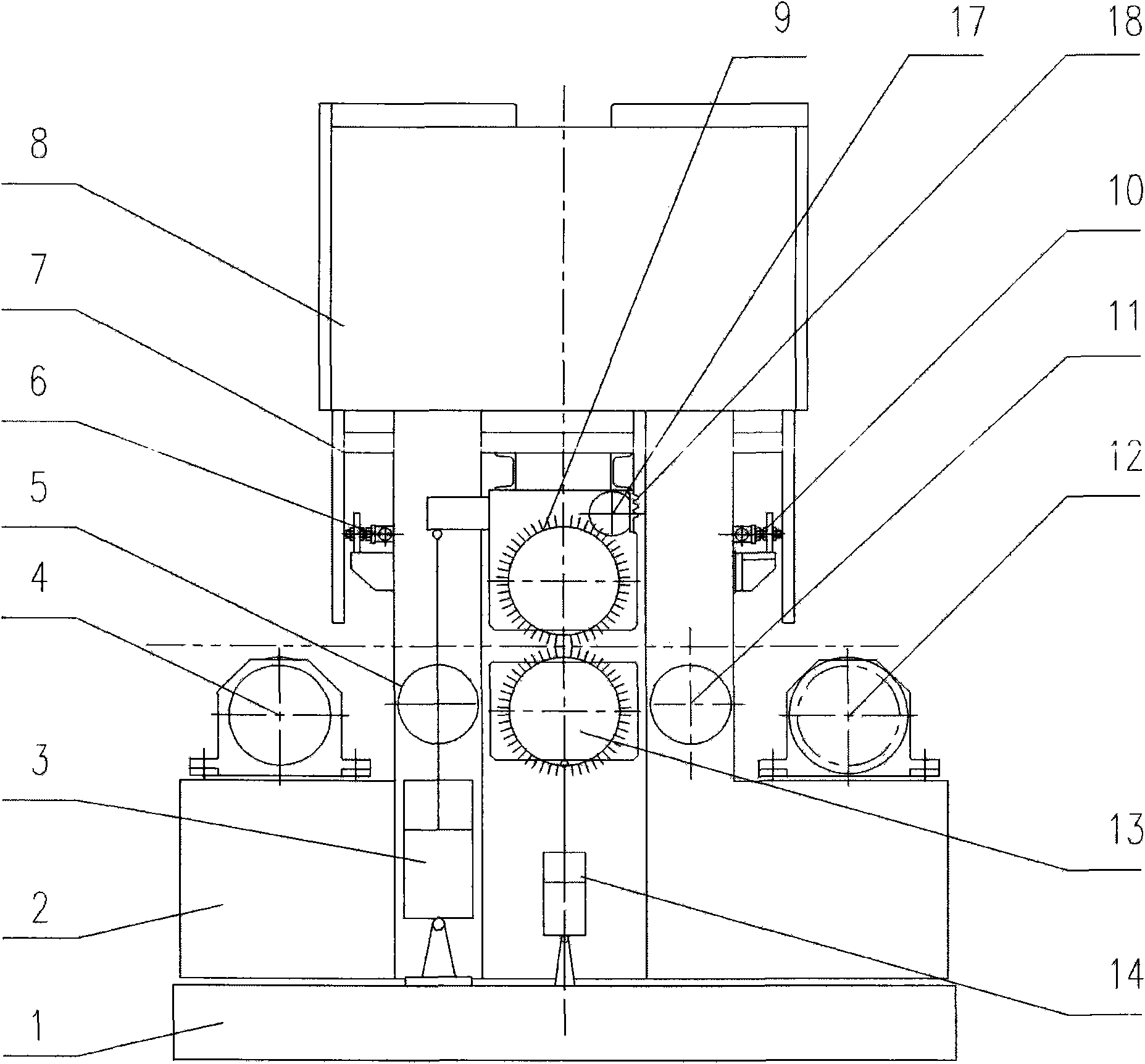

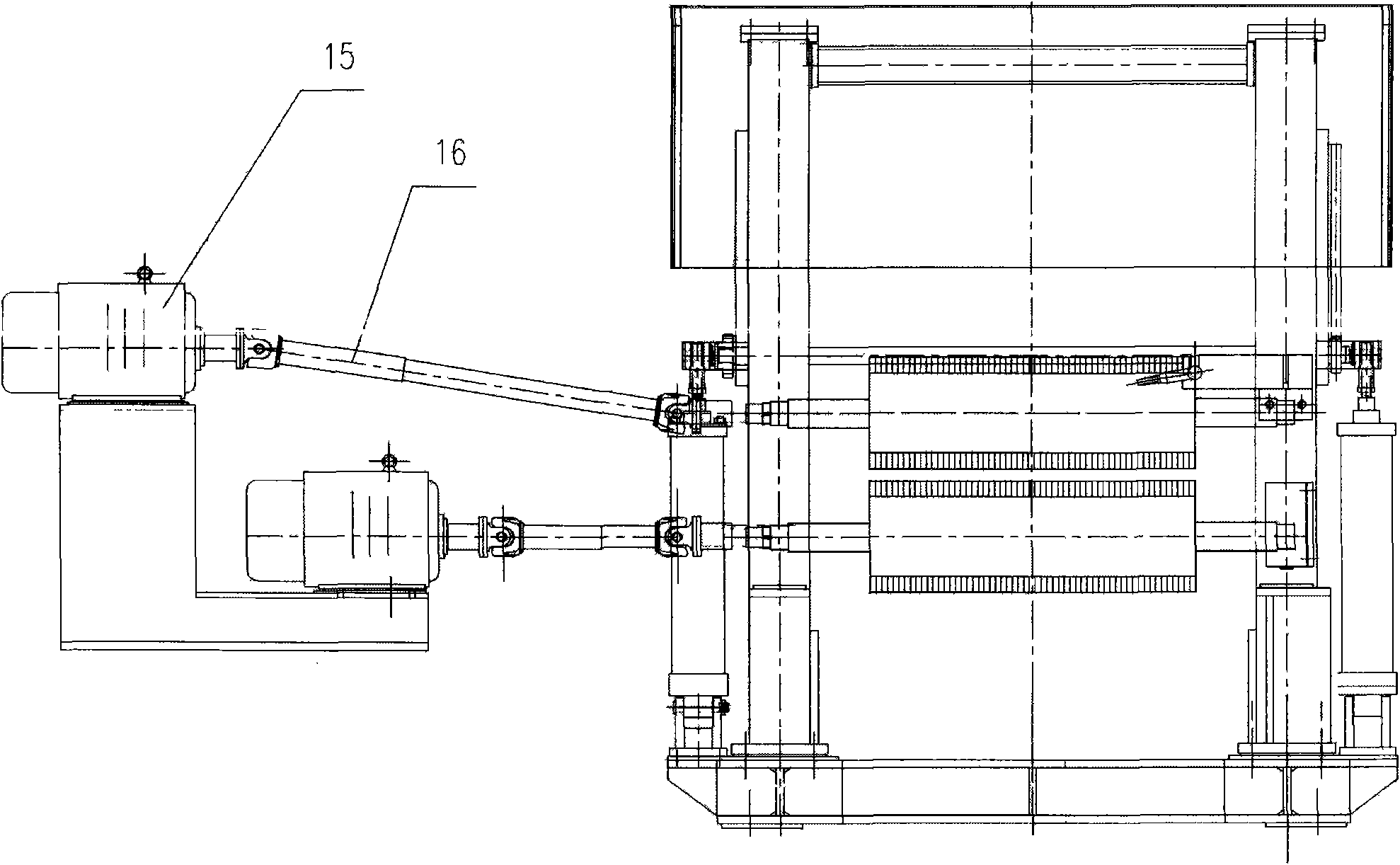

[0019] Combine now figure 1 , 2 The device design method of the present invention will be described in detail.

[0020] First of all, the equipment design method for removing scale on the surface of the strip of the present invention mainly includes the design of the brush roller transmission device, the design of the upper brush roller synchronous device, the design of the auxiliary conveying device, the design of the scale purging device, the design of the dust collection device and the equipped machine. seat design. Interrelationship and effect between described device designs are as follows:

[0021] The brush roller transmission device is used to remove the oxide scales on the two surfaces of the strip, and is one of the main designs of the present invention. It includes a pair of upper brush rollers 9 and lower brush rollers 13 with the same structure and arranged in parallel up and down. The inner layer of each upper and lower brush roller is made of cylindrical stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com