Calibration method for six-dimension force sensor calibration device with medium measurement range

A technology of a six-dimensional force sensor and a calibration method, which is applied in the calibration field of a six-dimensional force sensor calibration device with a range, can solve problems such as inability to achieve independent loading, affect calibration accuracy, and difficulty in ensuring accuracy, and achieve convenient calculation of coupling matrix and calibration accuracy High, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

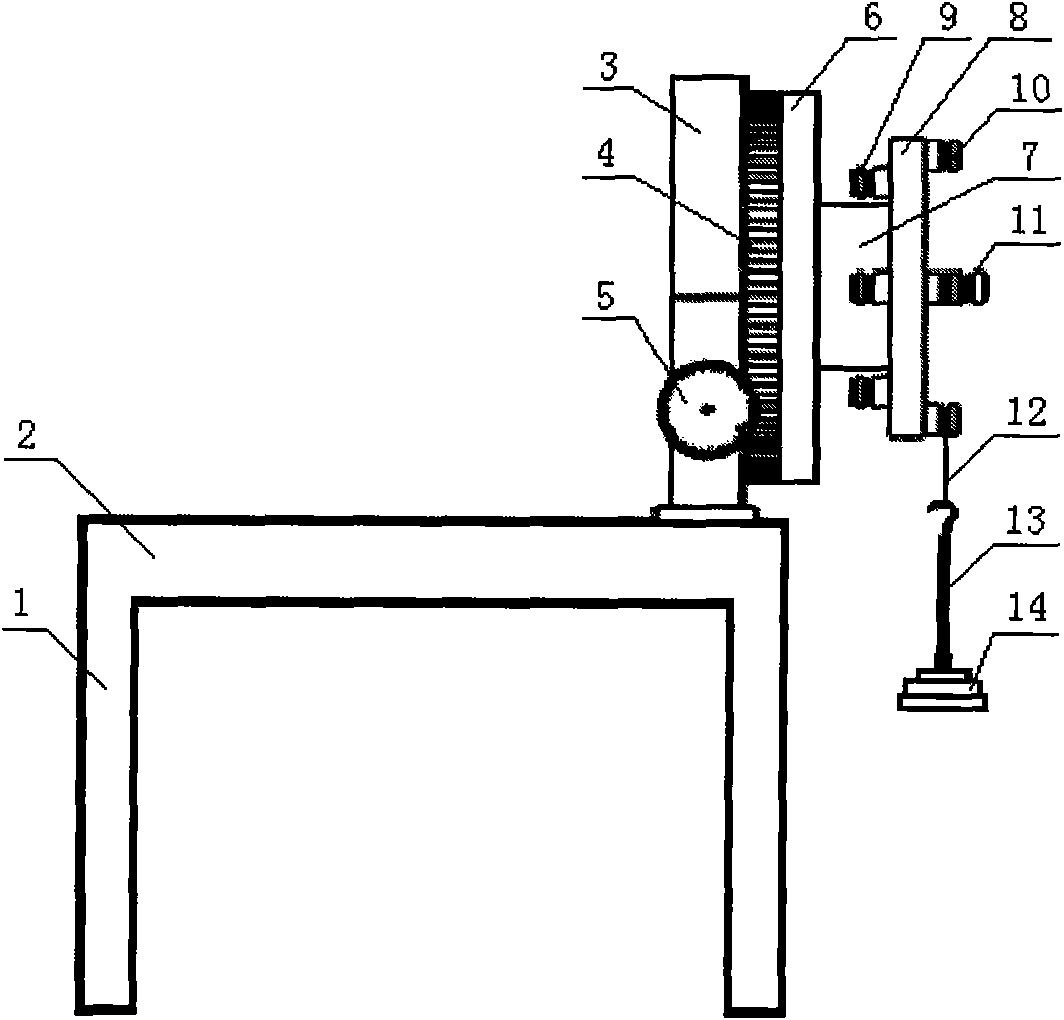

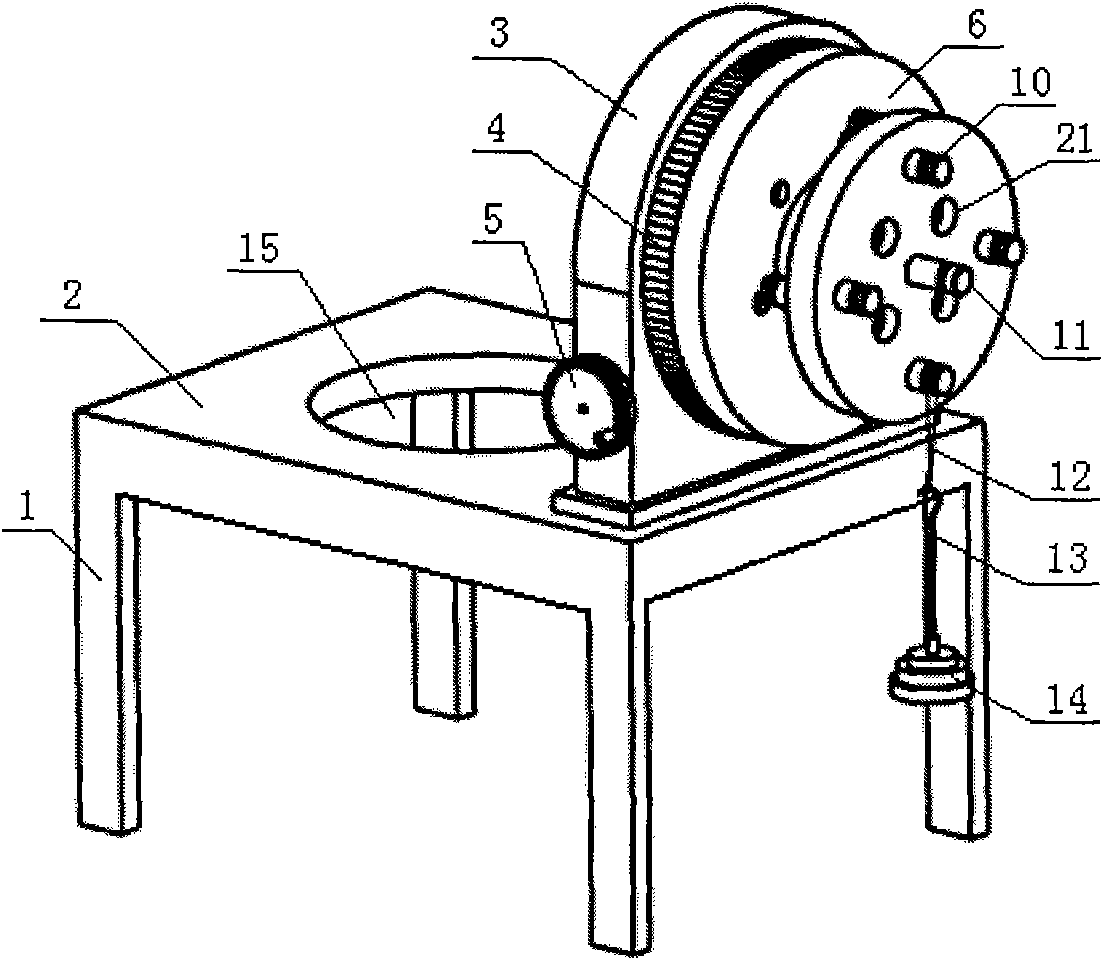

[0080] First, place the workbench support 1 of the six-dimensional force sensor calibration device on a flat ground, place the workbench 2 horizontally on the workbench support 1, and use a spirit level to calibrate the horizontal plane of the workbench 2 to ensure that the workbench 2 is horizontal. The turntable base 3 is vertically installed on one end of the workbench 2, and the turntable base 3, the turntable turntable 4 and the turntable handle 5 form a vertical turntable.

[0081] The loading plate 8 is installed on the six-dimensional force sensor 7 through a set of loading plate sensor mounting holes 21, the six-dimensional force sensor 7 is installed on the adapter plate sensor mounting hole 17 of the adapter plate 6, and the adapter plate 6 passes through a set of The adapter plate mounting hole 16 is installed on the turntable turntable 4 . The suspension hook 13 is hung on the rope 12, the weight 14 is placed on the suspension hook 13, and the rope 12 is hung on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com