Polymer photoelectron film and preparation method and application thereof

A polymer film and polymer technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems that the order degree of polymer composite films has not been substantially improved, and no research reports have been seen, so as to increase market competitiveness , simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

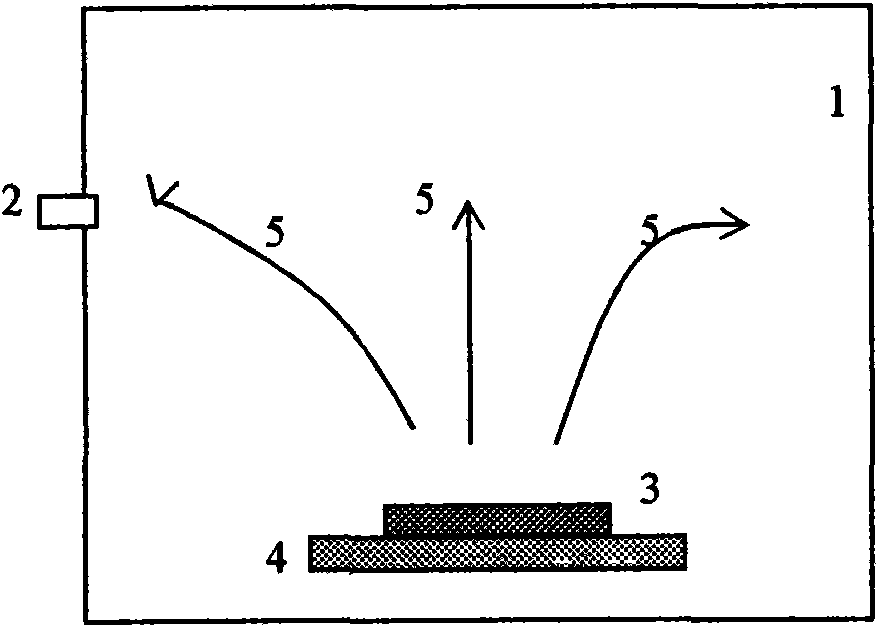

[0027] figure 1 Schematic illustration of controlling solvent evaporation time in polymer optoelectronic thin films at low ambient pressure. 1. Vacuum environment; 2. Air suction port, connected with vacuum mechanical pump; 3. Polymer film; 4. Support; 5. Solvent in polymer film.

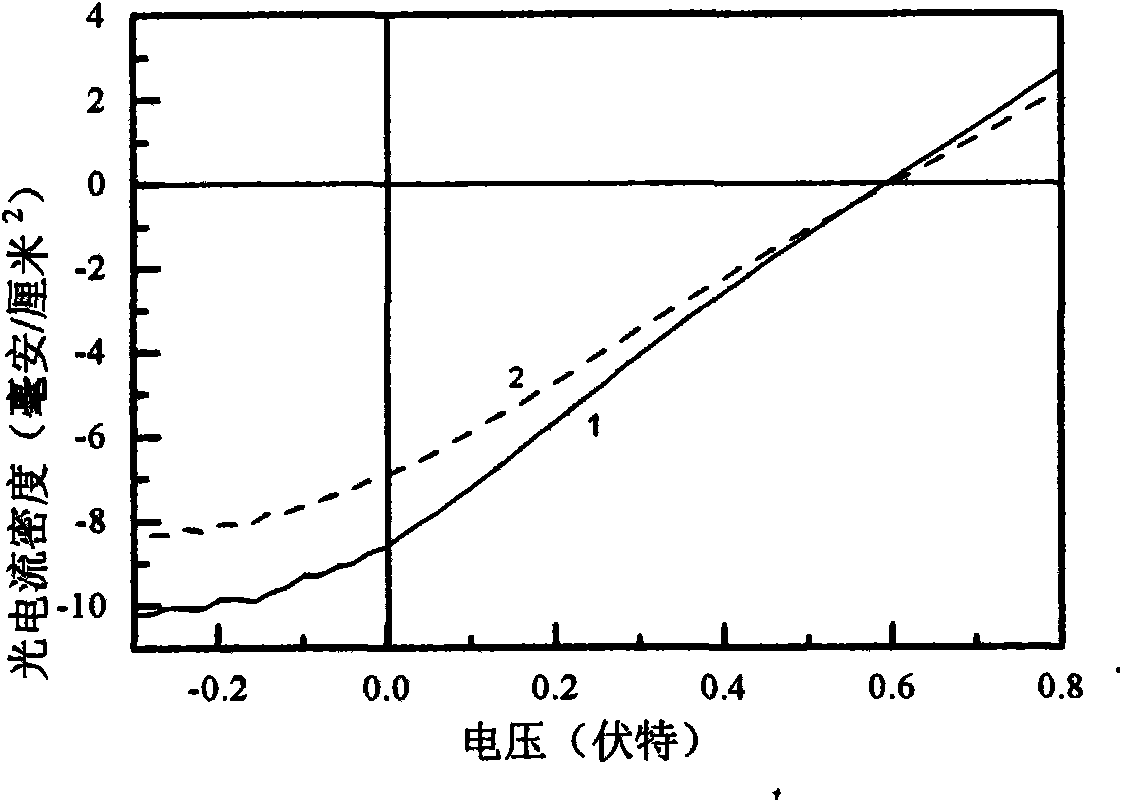

[0028] figure 2 P3HT with solvent (1,2-o-dichlorobenzene) volatilization time of 330 seconds under normal pressure (2 in the figure) and solvent (1,2-o-dichlorobenzene) volatilization time of 210 seconds under low pressure (1 in the figure) : PCBM device performance comparison.

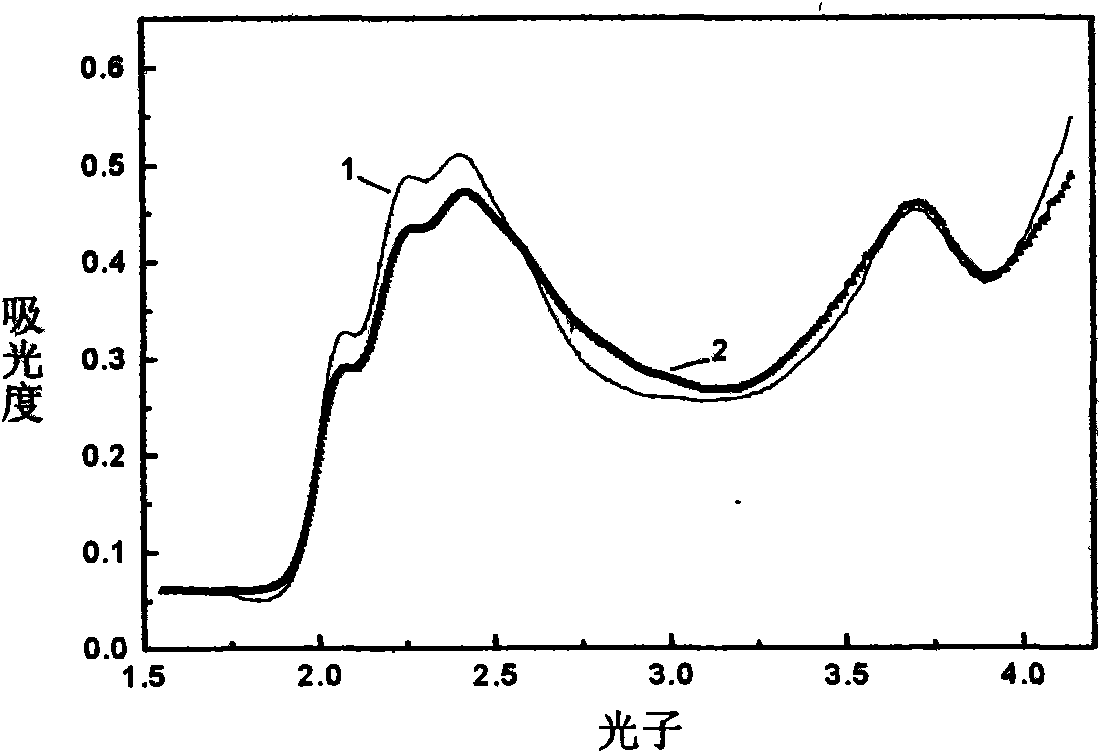

[0029] image 3 P3HT with solvent (1,2-o-dichlorobenzene) volatilization time of 330 seconds under normal pressure (2 in the figure) and solvent (1,2-o-dichlorobenzene) volatilization time of 210 seconds under low pressure (1 in the figure) :Comparison of absorption spectra of PCBM thin films.

[0030] The device structure is ITO / PEDOT:PSS 20nm / P3HT:PCBM 150nm / LiF 1nm / Al.

[0031] Specific operation:

[0032] The gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com