Computer vision precision measurement based multi-projection visual automatic geometric correction and splicing method

A computer vision, geometric correction technology, applied in the direction of TV, color TV, color TV components, etc., to achieve the effect of improving work efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

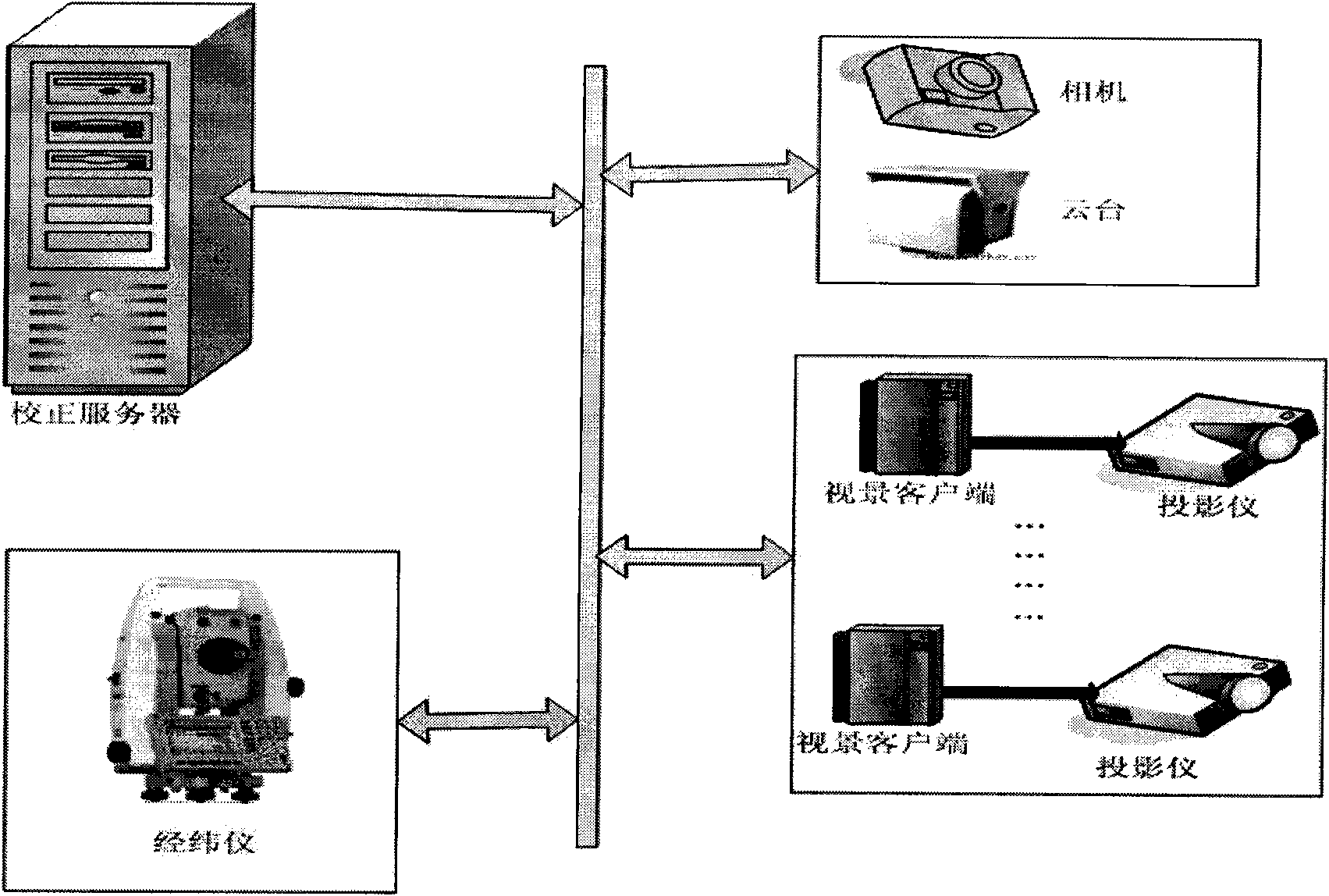

[0028] The hardware structure of multi-projection image geometric correction and stitching system can be found in figure 1. The whole system is composed of a calibration server, a computer-controlled theodolite, a computer-controlled digital camera, and a camera-mounted pan / tilt. The computer-controlled theodolite sends latitude and longitude control commands to the theodolite through the computer, and the rotation mechanism of the theodolite can drive the laser pointer on the theodolite to rotate the laser point to the specified spatial latitude and longitude position. Using the pixel-level mapping relationship between the image projected by the projector on the display wall and the computer frame buffer image, the latitude and longitude projected imaging grid is inversely mapped to the computer source image coordinate space grid.

[0029] When the computer sends the angle measurement command to the theodolite, the theodolite should be able to rotate to the specified latitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com