Migltol microcapsule tablet and preparation method thereof

A kind of technology of miglitol, microcapsule tablet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

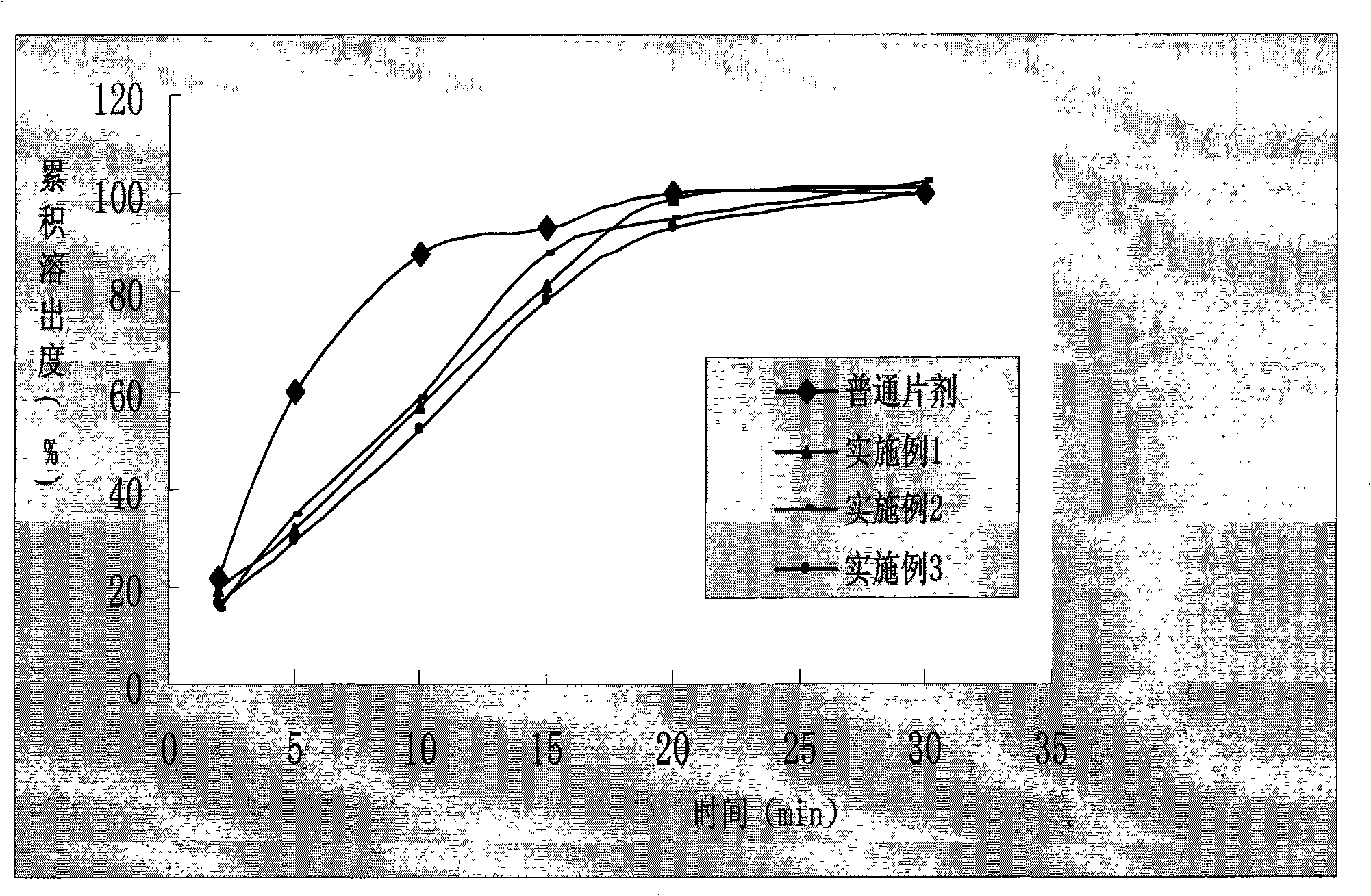

Examples

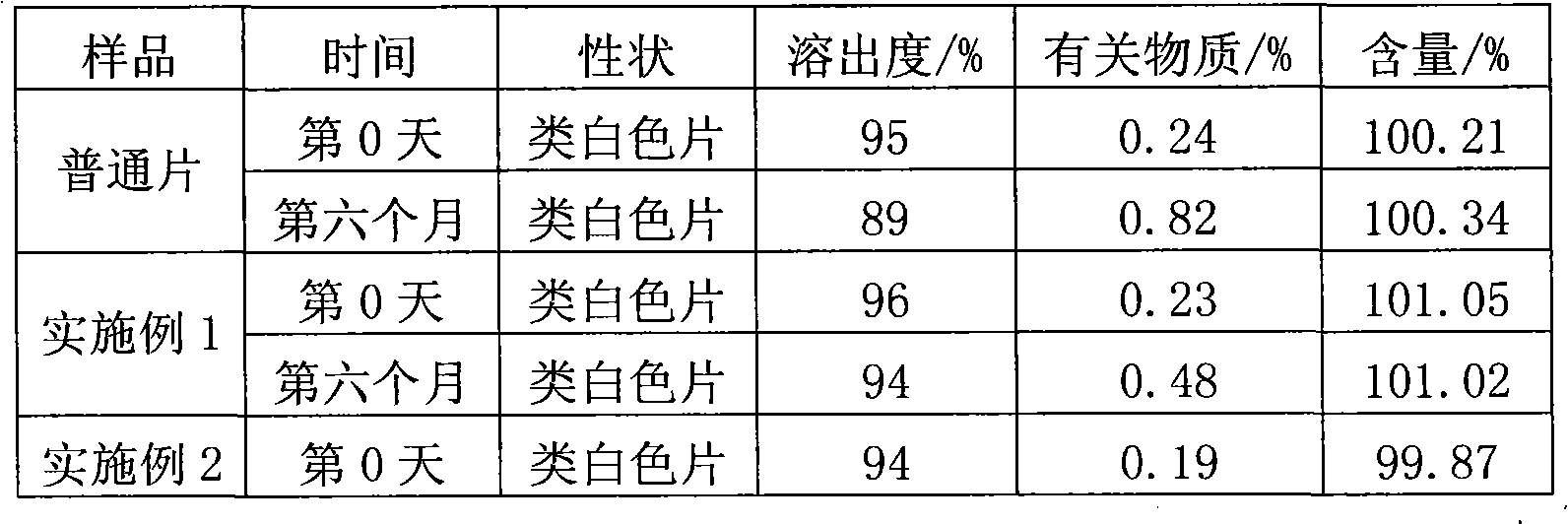

Embodiment 1

[0034] Microcapsule preparation of miglitol of the present invention

[0035] Name of raw and auxiliary materials Dosage / g

[0036] Miglitol 50

[0037] Starch 10

[0038] Type IV acrylic resin 30

[0039] MCC 50

[0040] CMS-Na 3

[0041] 70% ethanol aqueous solution

[0042] 1000 pieces in total

[0043] Preparation Process:

[0044] ① Pass the prescribed amount of Miglitol through a 60-120 mesh sieve, place it in a fluidized bed, and pass hot air into it to make it suspend and fluidize. The temperature of the hot air is 45-55°C;

[0045] ②Dissolve starch and type IV acrylic resin with an appropriate amount of 70% ethanol aqueous solution to make a 15% capsule material solution. The capsule material solution is atomized and continuously fed into the fluidized bed through the nozzle of the fluidized bed, where the atomization pressure is 0.25~0.30Mpa , The spraying speed is 50-60 rpm, and the air is continuously fed for drying. After the solution is sprayed, the heating is stopped, and the ...

Embodiment 2

[0048] Microcapsule preparation of miglitol of the present invention

[0049] Name of raw and auxiliary materials Dosage / g

[0050] Miglitol 50

[0051] Polyethylene glycol 15

[0052] HPMC 20

[0053] Lactose 60

[0054] CMC-Na 4

[0055] 70% ethanol aqueous solution

[0056] 1000 pieces in total

[0057] Preparation Process:

[0058] ① Pass the prescribed amount of Miglitol through a 60-120 mesh sieve, place it in a fluidized bed, and pass hot air into it to make it suspend and fluidize. The temperature of the hot air is 45-55°C;

[0059] ②Dissolve HPMC and polyethylene glycol with an appropriate amount of 70% ethanol aqueous solution to make a 15% capsule material solution. The capsule material solution is atomized and continuously fed into the fluidized bed through the nozzle of the fluidized bed, where the atomization pressure is 0.25~0.30Mpa , The spraying speed is 50-60 rpm, and the air is continuously fed for drying. After the solution is sprayed, the heating is stopped, the material...

Embodiment 3

[0062] Microcapsule preparation of miglitol of the present invention

[0063] Name of raw and auxiliary materials Dosage / g

[0064] Miglitol 50

[0065] PVP 35

[0066] Calcium hydrogen phosphate 20

[0067] MCC 40

[0068] Copovidone S-630 4

[0069] 70% ethanol aqueous solution

[0070] 1000 pieces in total

[0071] Preparation Process:

[0072] ① Pass the prescribed amount of Miglitol through a 60-120 mesh sieve, place it in a fluidized bed, and pass hot air into it to make it suspend and fluidize. The temperature of the hot air is 45-55°C;

[0073] ②Dissolve PVP with an appropriate amount of 70% ethanol aqueous solution to make a 20% capsule material solution. The capsule material solution is atomized and continuously fed into the fluidized bed through the nozzle of the fluidized bed. The atomization pressure is 0.25~0.30Mpa, and the spraying speed is 50-60 rpm, continuous air drying, stop heating after the solution is sprayed, cool and discharge, obtain miglitol microcapsules for use;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com