A kind of urea microcapsule preparation and preparation method thereof

A technology of urea and microcapsules, which is applied in the field of urea microcapsule preparations and its preparation, can solve problems such as unstable properties of urea, restrictions on the medical application of urea, rebound rebound of urea intracranial pressure, etc., so as to avoid peak and valley phenomena and enhance Therapeutic effect, the effect of reducing side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

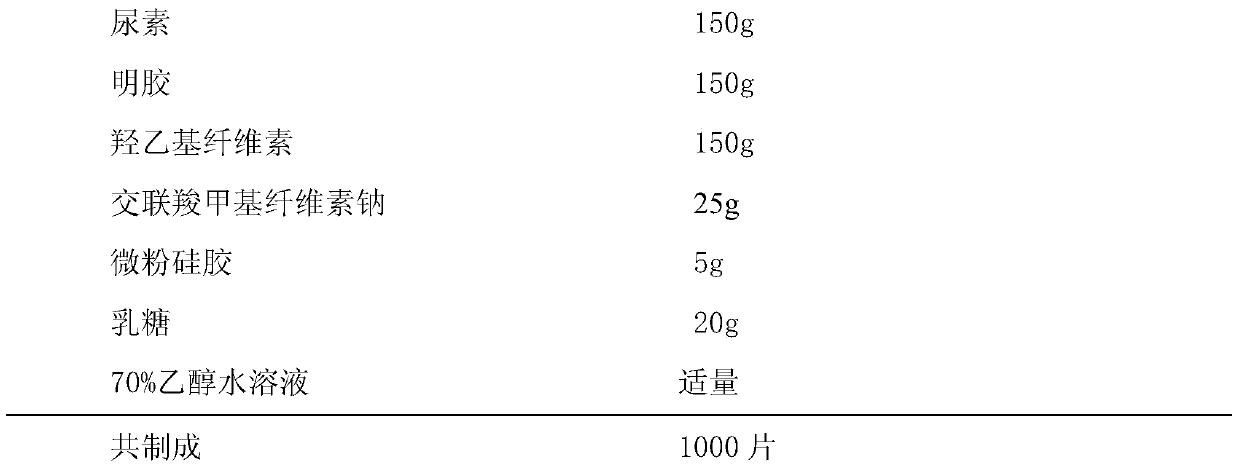

[0031] The preparation of embodiment 1 urea microcapsule tablet of the present invention

[0032]

[0033] Preparation Process:

[0034] ① Pass the prescribed amount of urea through a 60-120-mesh sieve, place it in a fluidized bed, pass hot air into it to suspend and fluidize it, and the temperature of the hot air is 45-55°C;

[0035] ② Dissolve gelatin and hydroxyethyl cellulose with an appropriate amount of 70% ethanol aqueous solution to make a 15% capsule material solution. The capsule material solution is atomized through the nozzle of the fluidized bed and continuously added to the fluidized bed, where the atomization pressure is 0.25-0.30 Mpa, the spraying speed is 50-60rpm, after the solution is sprayed, continue to enter the air and dry until the moisture is less than 2%, stop heating, cool and discharge, and obtain urea microcapsules for use;

[0036] ③ Mix the prepared urea microcapsules with the prescribed amount of croscarmellose sodium, micropowder silica gel...

Embodiment 2

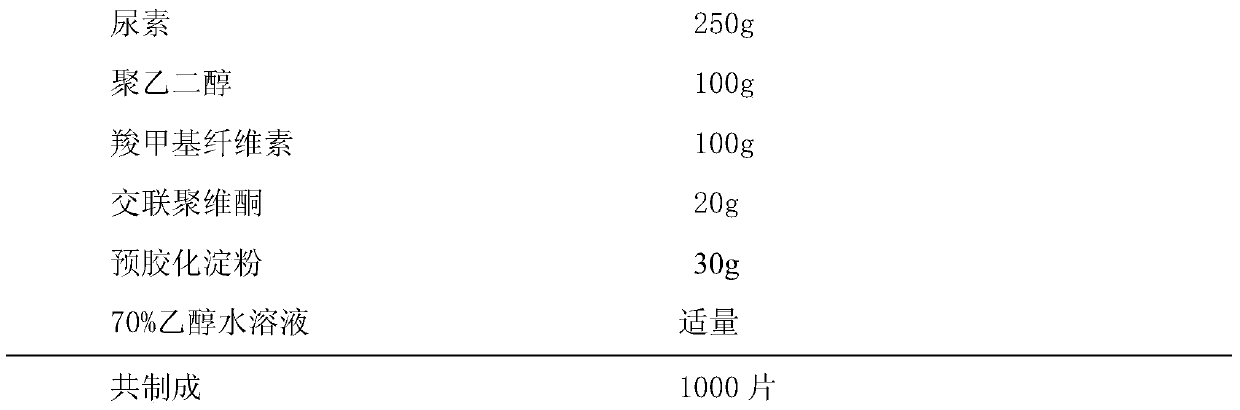

[0037] Embodiment 2 The preparation of urea microcapsule tablet of the present invention

[0038]

[0039] Preparation Process:

[0040] ① Pass the prescribed amount of urea through a 60-120-mesh sieve, place it in a fluidized bed, pass hot air into it to suspend and fluidize it, and the temperature of the hot air is 45-55°C;

[0041] ②Dissolve polyethylene glycol and carboxymethyl cellulose with an appropriate amount of 70% ethanol aqueous solution to make a 15% capsule material solution, and the capsule material solution is atomized through the nozzle of the fluidized bed and continuously added to the fluidized bed, wherein the atomization pressure is 0.25-0.30Mpa, the spraying speed is 50-60rpm, after the solution is sprayed, continue to enter the air and dry until the water content is less than 2%, stop heating, cool and discharge, and obtain urea microcapsules for use;

[0042] ③ Mix the prepared urea microcapsules with the prescribed amount of pregelatinized starch a...

Embodiment 3

[0043] Embodiment 3 The preparation of urea microcapsule tablet of the present invention

[0044]

[0045]

[0046] Preparation Process:

[0047] ① Pass the prescribed amount of urea through a 60-120-mesh sieve, place it in a fluidized bed, pass hot air into it to suspend and fluidize it, and the temperature of the hot air is 45-55°C;

[0048] ② Dissolve polyvinylpyrrolidone and hydroxypropyl cellulose with an appropriate amount of 70% ethanol aqueous solution to make a 15% capsule material solution, and the capsule material solution is atomized through the nozzle of the fluidized bed and continuously added to the fluidized bed, where the atomization pressure is 0.25 ~0.30Mpa, the spraying speed is 50~60rpm, after the solution is sprayed, continue to enter the air and dry until the water content is less than 2%, stop heating, cool and discharge, and obtain urea microcapsules for use;

[0049] ③ Mix the prepared urea microcapsules with the prescribed amount of croscarmel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com