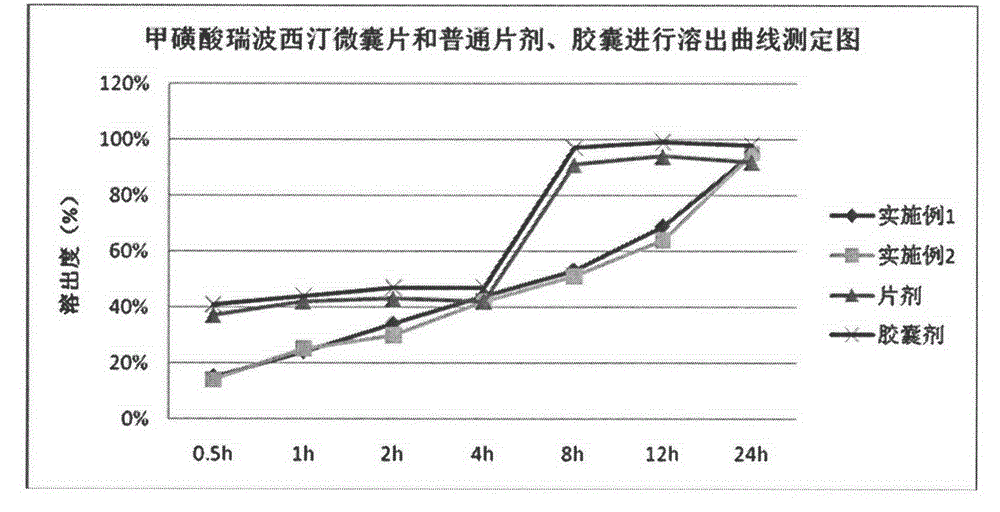

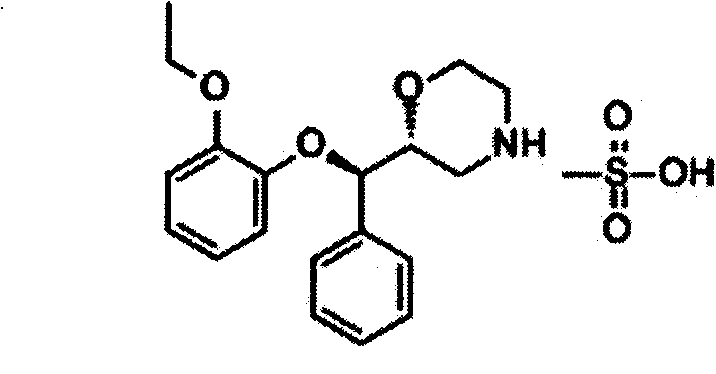

Reboxetine mesylate microencapsule tablet and preparation method thereof

A technology of reboxetine mesylate and microcapsules, which is applied in the field of reboxetine microcapsules and its preparation, can solve the problems of increasing adverse drug reactions, increasing blood drug concentration, adverse reactions, etc., and achieve improved bioavailability , enhance the therapeutic effect, reduce the effect of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

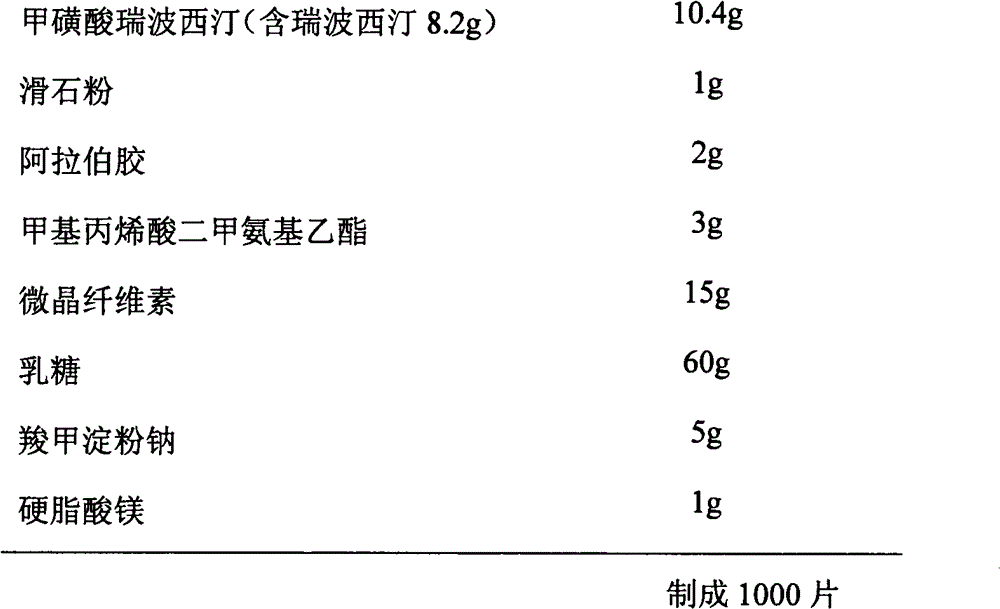

Embodiment 1

[0034] prescription:

[0035]

[0036]Pass the prescribed amount of reboxetine mesylate through a 80-mesh sieve, put it in a fluidized bed, feed hot air, the temperature of the hot air is 45°C, add the prescribed amount of talcum powder; mix gum arabic and dimethyl methacrylate Aminoethyl ester is made into 15% capsule material solution with an appropriate amount of 70% ethanol aqueous solution for subsequent use, and the capsule material solution is atomized by a fluidized bed nozzle, sprayed and attached to the surface of the micropowder, the spray atomization pressure is 0.35Mpa, and the spray speed is 45rpm, continuous ventilating and drying, after coating finishes, stop heating, cool to 30 ℃, discharge, obtain reboxetine mesylate microcapsules; Mix the prepared reboxetine mesylate microcapsules with the microcrystalline Cellulose, lactose, sodium carboxymethyl starch, and magnesium stearate are mixed evenly, and directly compressed into tablets.

Embodiment 2

[0038] prescription:

[0039]

[0040] Pass the prescribed amount of reboxetine mesylate through a 80-mesh sieve, place it in a fluidized bed, feed hot air, the temperature of the hot air is 45°C, add the prescribed amount of magnesium stearate; mix polyvinyl alcohol and hypromellose The base cellulose is made into 12% capsule material solution with an appropriate amount of 70% ethanol aqueous solution for subsequent use. The capsule material solution is atomized through a fluidized bed nozzle and sprayed on the surface of the micropowder. The spray atomization pressure is 0.40Mpa, and the spray speed is 45rpm, continuous ventilating and drying, after coating finishes, stop heating, cool to 30 ℃, discharge, obtain reboxetine mesylate microcapsules; Mix the prepared reboxetine mesylate microcapsules with the prescribed amount of hydrogen phosphate Calcium, starch, sodium starch glycolate, and magnesium stearate are mixed evenly, and directly compressed into tablets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com