Steel-concrete combined continuous rigid frame bridge construction method for cantilever jointing steel box section

A construction method and technology for rigid frame bridges, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problem of high sensitivity of continuous rigid frame bridge materials and construction quality, affecting the normal service performance of bridges, structural durability, technical Require high-level issues, achieve the effect of reducing construction equipment requirements, avoiding concrete cracking under tension, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

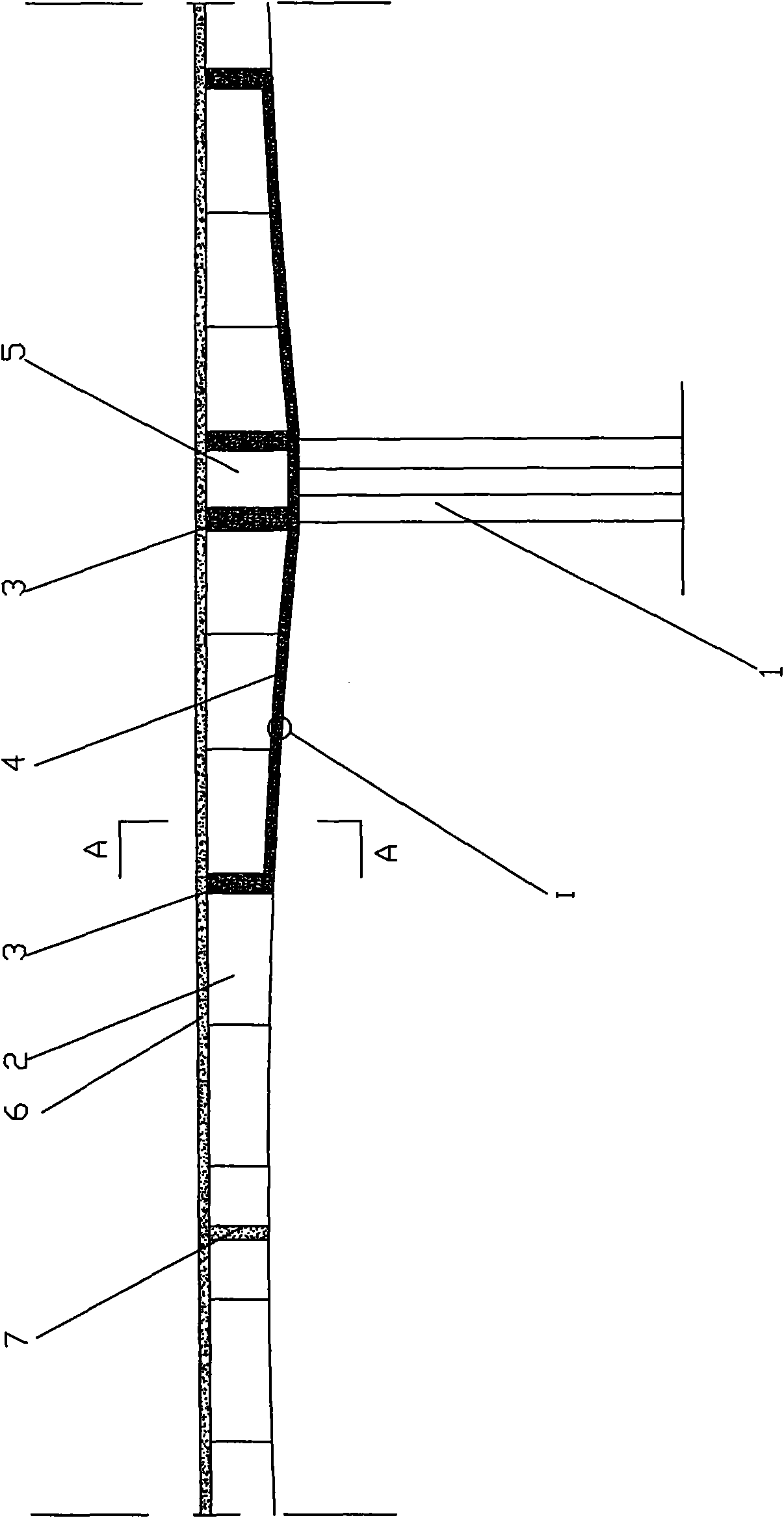

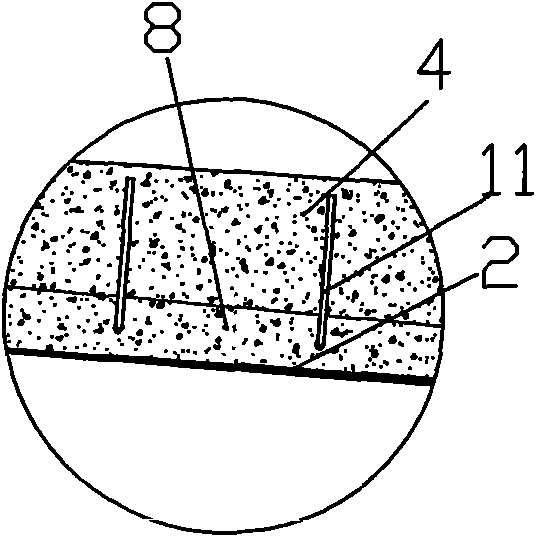

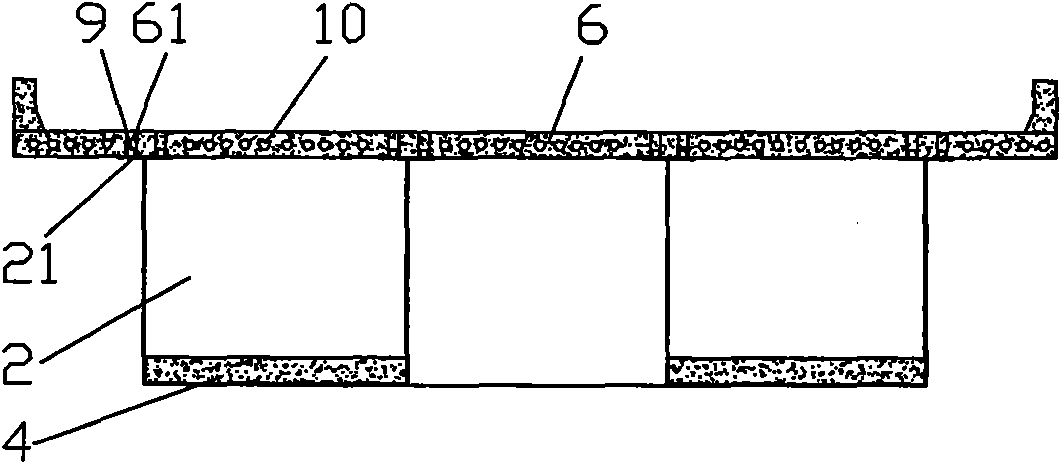

[0024] figure 1 This is a schematic diagram of the structure after construction of this method, figure 2 for figure 1 Enlarged view at I, image 3 for figure 1 Take the A-A section view, Figure 4 This is an enlarged view of the partial longitudinal section of the concrete bridge road slab under the negative bending moment of the present invention, as shown in the figure: The construction method of the steel-concrete combined continuous rigid frame bridge with cantilever assembled steel box segments of the present invention includes the following steps:

[0025] a. Complete the construction of pier 1, install the pier top steel box girder section 5 on the top of the pier 1, and pour the pier top diaphragm 3 to increase the strength;

[0026] b. The prefabricated steel box girder sections 2 are respectively cantilevered to both sides of the bridge pier 1; and the two adjacent piers 1 are cantilevered to the mid-span area respectively. The cross-sectional shape of the steel box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com