Solar energy photo-thermal high-temperature utilization system

A solar energy and photothermal technology, applied in the field of solar photothermal high temperature utilization system, can solve the problems of high cost, high price of tracking device related components, unstable performance, etc. Simple and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

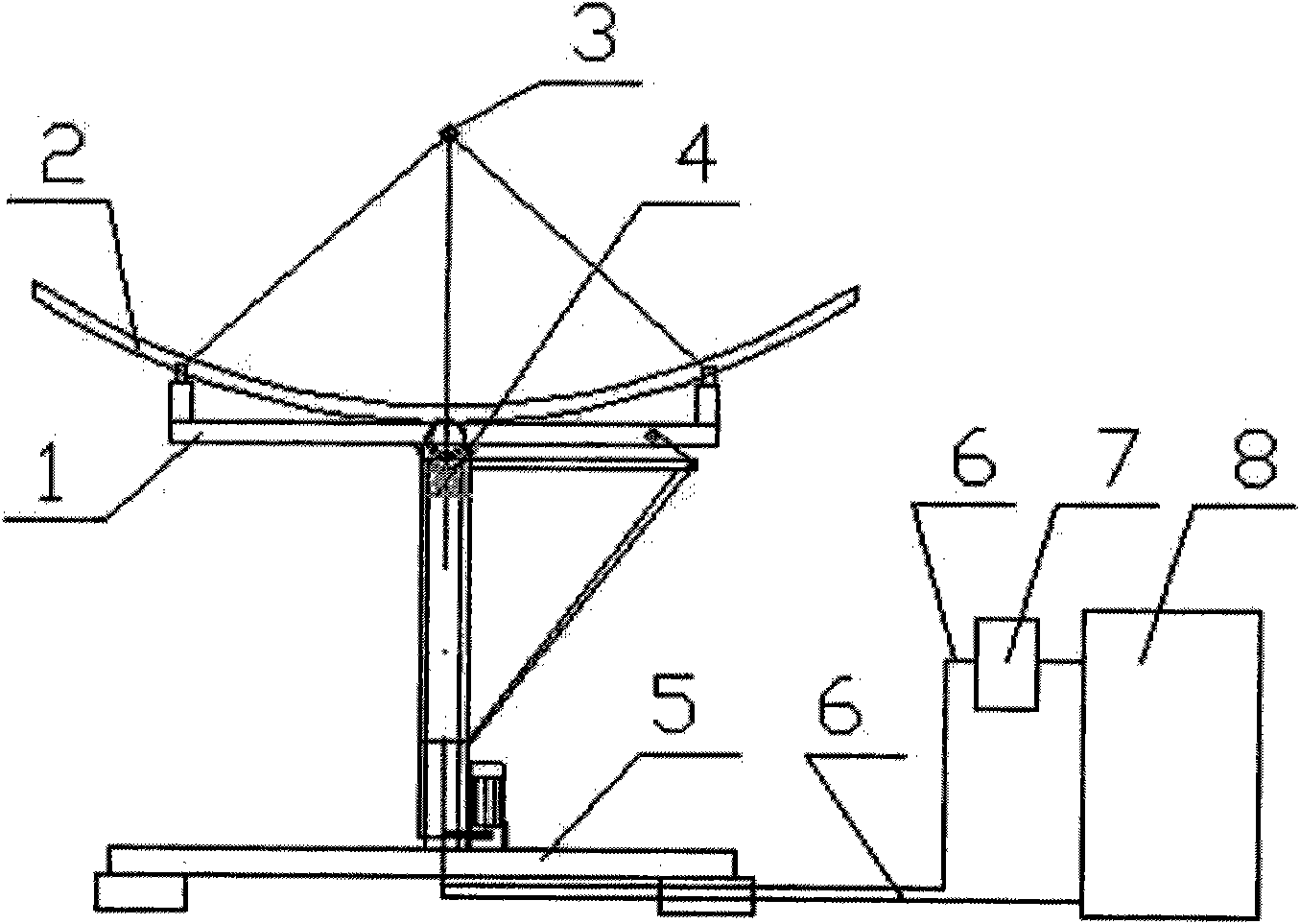

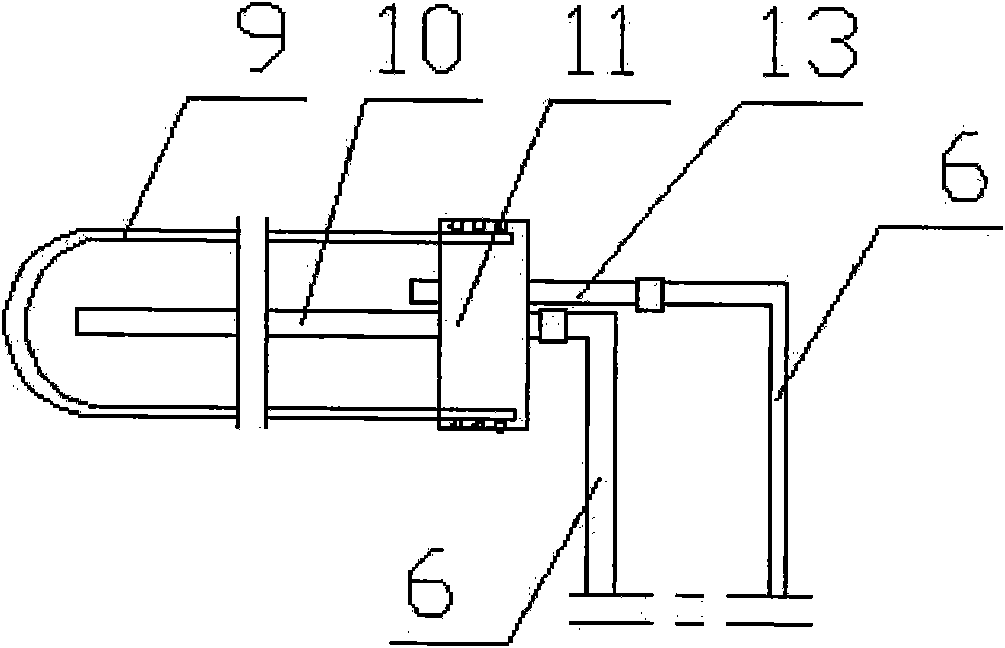

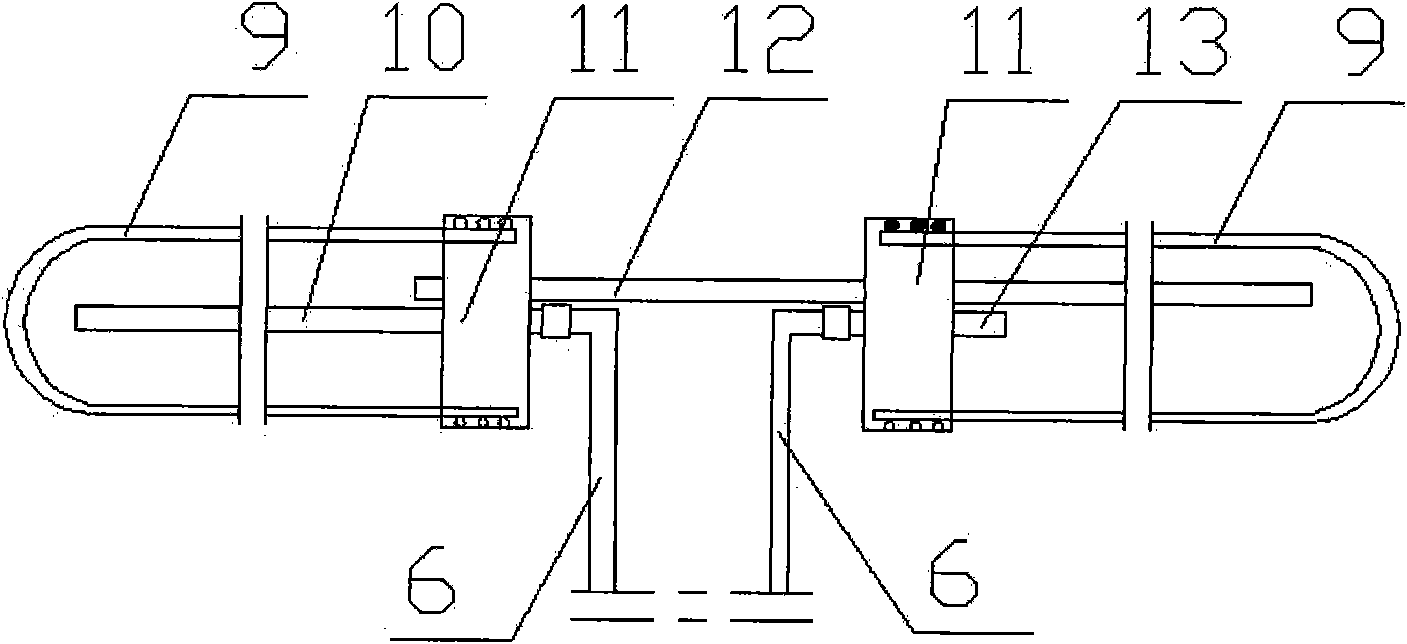

[0018] With reference to accompanying drawing, the present invention comprises main engine 1, oil pump 7 and heat exchanger 8, and described main engine 1 comprises main engine 1, oil pump 7 and heat exchanger 8 and heat medium thereof by concentrating device 2, heat collector 3, tracking device , the main engine 1 is composed of a concentrating device 2, a heat collector 3, a tracking device 4 and a base 5, the heat collector 3, an oil pump 7 and a heat exchanger 8 are connected by an oil pipe 6, and the heat collector 3 is connected by The bracket is installed and fixed on the focusing point of the concentrating device 2, and the heat exchanger 8 is connected to at least one main engine 1; the heat collector 3 is composed of a heat collecting pipe 9 and its seal 11, an oil inlet pipe 10 and an oil return pipe 13 ; The heat collecting tube 9 adopts a U-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com