Implanted piezoelectric ceramic microphone and manufacturing method thereof

A technology of piezoelectric ceramics and microphones, which is applied in the field of bionics in biomedical engineering, can solve the problems that implanted microphones have not achieved major breakthroughs, achieve good frequency response curves, improve response sensitivity, and save assembly space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

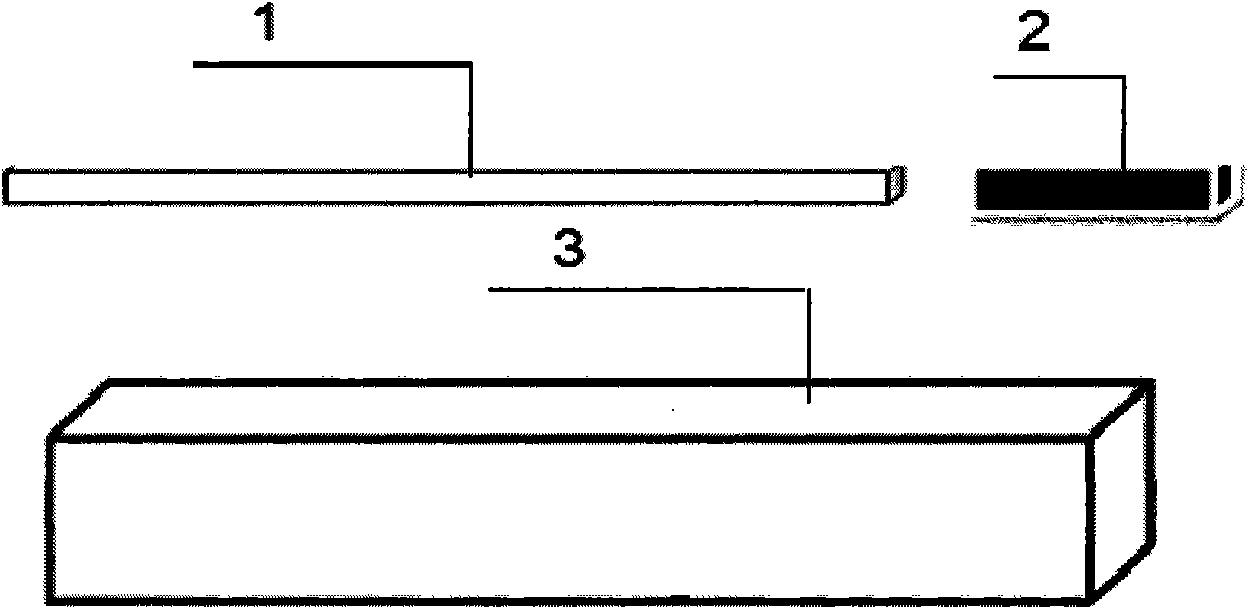

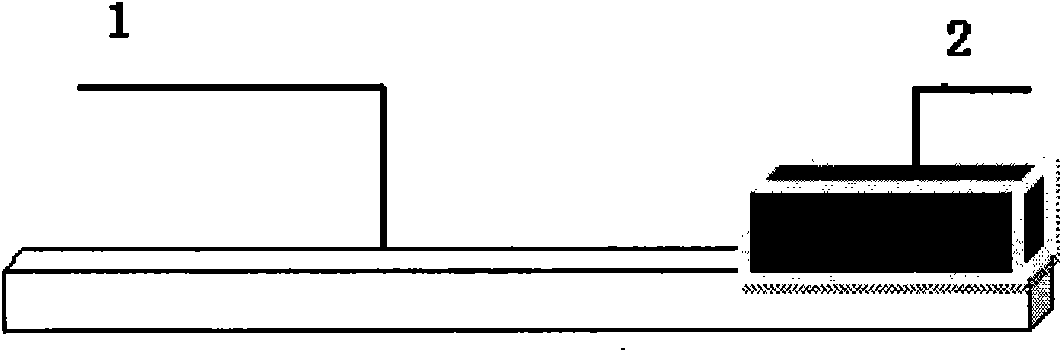

[0035] Example 1 Preparation of Implantable Piezoelectric Ceramic Microphone

[0036] Biological glue pastes and fixes the preamplifier (LMV1032 type) system on one end of the piezoelectric ceramic bimorph, and the piezoelectric ceramic bimorph is 2.0×width 1.0×0.3mm thick;

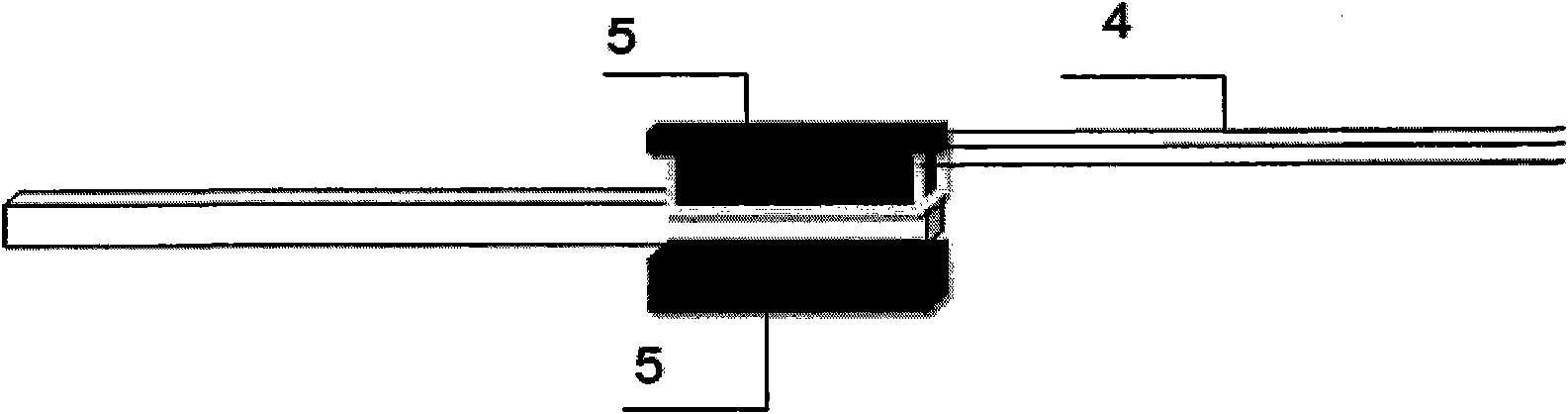

[0037] The preamplifier chip is pasted and fixed on one end of the piezoelectric ceramic double chip with epoxy resin, and one position of the piezoelectric ceramic double chip and the preamplifier chip is micro-welded; the preamplifier chip is also connected to the signal output wire, working The power wire and the ground wire are connected by micro-welding, and 3 copper core enameled wires with a diameter of 0.1mm are drawn out, each wire is 200mm long, and then both sides of the package are cured with epoxy resin.

[0038] Place the above components in a square cylindrical shielded copper shell with a wall thickness of 0.1 mm: the shielded copper shell is 3.0 long x 1.6 mm wide x 1.3 mm high and kept in ...

Embodiment 2

[0040] Example 2 Preparation of Implantable Piezoelectric Ceramic Microphone

[0041] Biological glue pastes and fixes the preamplifier (LMV1032 type) system on one end of the piezoelectric ceramic bimorph, and the piezoelectric ceramic bimorph is 4.0×width 1.0×0.3mm thick;

[0042] The preamplifier chip is pasted and fixed on one end of the piezoelectric ceramic double chip with epoxy resin, and one position of the piezoelectric ceramic double chip and the preamplifier chip is micro-welded; the preamplifier chip is also connected to the signal output wire, working The power wire and the ground wire are connected by micro-welding, and 3 copper core enameled wires with a diameter of 0.1mm are drawn out, each wire is 200mm long, and then both sides of the package are cured with epoxy resin.

[0043] Place the above components in a square cylindrical shielded copper shell with a wall thickness of 0.1mm (length 5.0×width 1.6mm×height 1.3mm) and keep it in the center, fill the gap ...

Embodiment 3

[0045] Example 3 Preparation of Implantable Piezoelectric Ceramic Microphone

[0046] Biological glue pastes and fixes the preamplifier (LMV1032 type) system on one end of the piezoelectric ceramic bimorph, and the piezoelectric ceramic bimorph is 6.0mm long x 2.0mm wide x 0.3mm thick;

[0047] The preamplifier chip is pasted and fixed on one end of the piezoelectric ceramic double chip with epoxy resin, and one position of the piezoelectric ceramic double chip and the preamplifier chip is micro-welded; the preamplifier chip is also connected to the signal output wire, working The power wire and the ground wire are connected by micro-welding, and 3 copper core enameled wires with a diameter of 0.1mm are drawn out, each wire is 200mm long, and then both sides of the package are cured with epoxy resin.

[0048] Place the above components in a square cylindrical shielded copper shell with a wall thickness of 0.1mm (length 7.0×width 3mm×height 1.3mm) and keep it in the center, fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com