Manufacturing technique of colored veneer bamboo

A production process, thin bamboo technology, applied in the field of colored thin bamboo production technology, can solve problems such as monotony, achieve the effect of improving visual characteristics, firm color fastness and light resistance, and increasing product added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

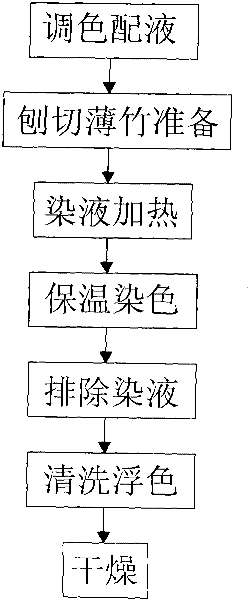

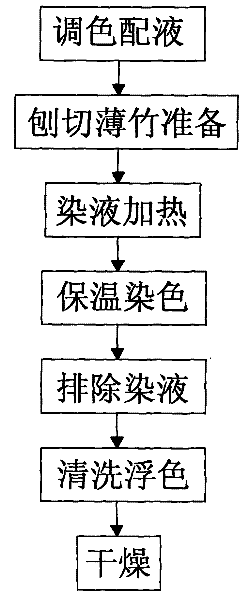

[0020] The technical solution of the invention will be further described below in conjunction with the accompanying drawings.

[0021] Soft water is used as the base liquid, and the temperature of the soft water is 23-27°C, preferably 25°C. Add 0.3-0.7% water-soluble bamboo dyeing agent in soft water according to the weight ratio of soft water, the preferred range is 0.4-0.6%, the best is to add 0.5% water-soluble bamboo dyeing agent, the color of the dyeing agent is carried out according to actual needs Select, add 0.01-0.1% penetrating agent according to the weight ratio of soft water at the same time, the preferred range is 0.03-0.07%, the model of the penetrating agent is 50805K, add 0.01-0.1% leveling agent, the preferred range is 0.03-0.07%, The model of the leveling agent is 50805M, after stirring evenly for 4-7 minutes, add 0.01-0.1% dyeing accelerator according to the weight ratio of soft water, the preferred range is 0.03-0.07%, the model of the dyeing accelerator is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com