Clean galvanized part silicate colorful passivating process

A silicate and clean technology, applied in the coating process of metal materials, etc., can solve the problems of high cost, low cost, poor brightness and corrosion resistance, etc., and achieve improved corrosion resistance, easy cost and efficiency, and corrosion resistance excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

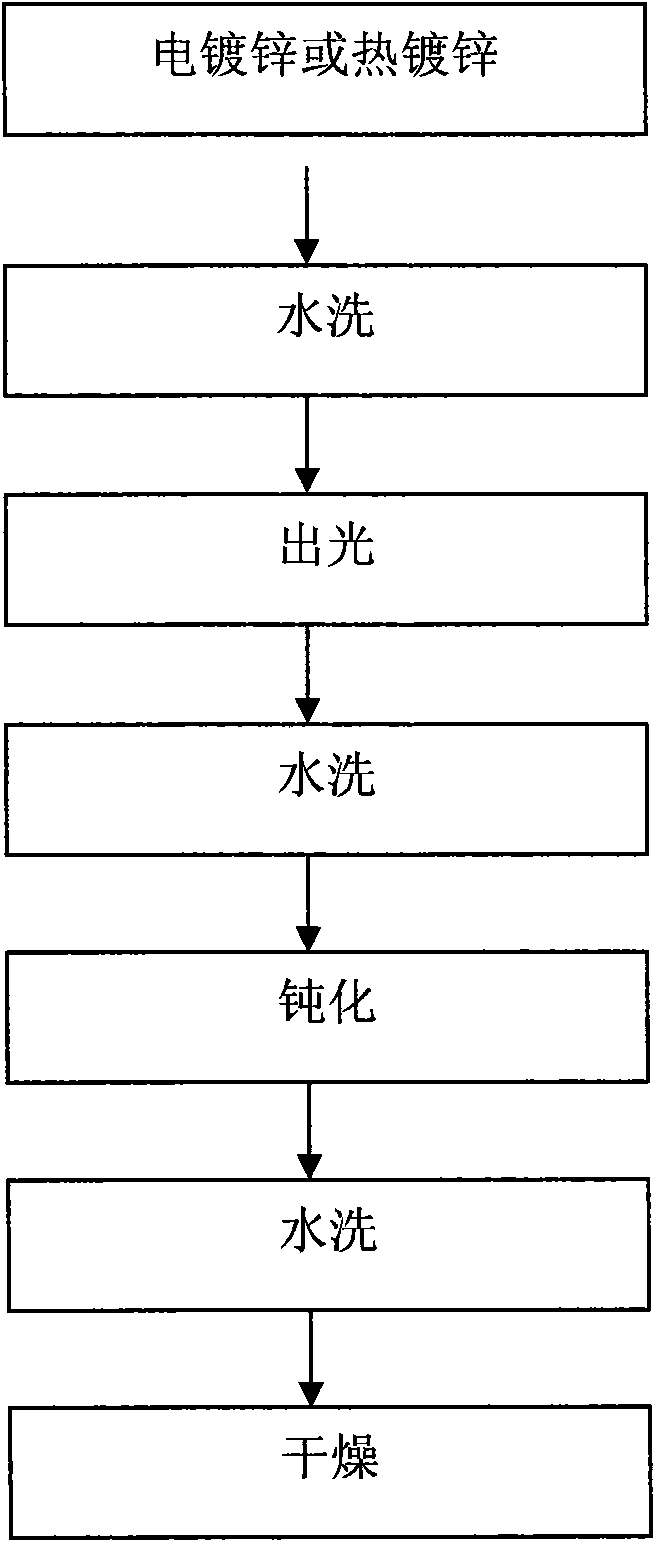

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: The passivation process is used for the passivation treatment of acid electrogalvanized steel sheet.

[0025] The 80mm×40mm×1.5mm low-carbon steel plate is put into the electroplating solution for electroplating after pre-treatment such as rust removal, degreasing and activation before electroplating. The composition and operating conditions of the galvanizing process are: ZnCl 2 50g / L, KCl200g / L, Chloride Zinc No. 1 Additive 12mL / L, Chloride Zinc No. 2 Additive 5mL / L, the pH value of the plating solution is kept at about 6.0, and the current density is 1.0A / dm 2, the temperature is room temperature, and the plating time is 25 minutes.

[0026] Preparation of light solution: by HNO 3 (65%) 10mL / L and H 2 composed of O;

[0027] Preparation of passivation solution: raw materials are sodium silicate 5g / L, boric acid 2g / L, H 2 o 2 (30%) 25mL / L, HNO 3 (65%) 3mL / L, H 2 SO 4 (98%)5mL / L, KMnO 4 0.3g / L, NaAc 2g / L and H 2 O composition; the preparation ...

Embodiment 2

[0030] Embodiment 2: The passivation process is used for passivation treatment of hot-dip galvanized steel sheets.

[0031] The 100mm×60mm×2mm Q235 steel plate is subjected to pre-treatments such as rust removal, degreasing, and galvanizing before hot-dip galvanizing, and then hot-dip galvanized in a graphite crucible filled with zinc liquid. The galvanizing temperature is 450°C. The dipping time is 1 minute, and water cooling is carried out after the zinc layer is solidified.

[0032] Preparation of light solution: by HNO 3 (65%) 15mL / L and H 2 O forms the light-emitting liquid;

[0033] Preparation of passivation solution: raw materials are sodium silicate 10g / L, boric acid 3g / L, H 2 o 2 (30%) 30mL / L, HNO 3 (65%) 4mL / L, H 2 SO 4 (98%) 4mL / L, KMnO 4 0.5g / L, NaAc 1g / L and H 2 O composition, preparation method is the same as embodiment 1, with dilute H 2 SO 4 Or dilute NaOH solution to adjust the pH value of the passivation solution to 0.8.

[0034] Immerse the hot...

Embodiment 3

[0036] Embodiment 3: This passivation process is used for the passivation treatment after alkaline electrogalvanizing of a certain machine steel shell.

[0037] Before passivation, the steel shell of a certain machine is electroplated after pretreatment (rust removal, oil removal, weak etching, pre-dipping, etc.), and the composition and operating conditions of the galvanizing process are: ZnO 10g / L , NaOH 120g / L, DPE-1 additive 5mL / L, current density 2.5A / dm 2 , The temperature is room temperature, and the electroplating time is 30 minutes.

[0038] Preparation of light solution: by HNO 3 (65%) 5mL / L and H 2 O forms the light-emitting liquid;

[0039] Preparation of passivation solution: raw materials are sodium silicate 8g / L, boric acid 2g / L, H 2 o 2 (30%) 20mL / L, HNO 3 (65%) 5mL / L, H 2 SO 4 (98%) 3mL / L, KMnO 4 0.2g / L, NaAc 3g / L and H 2 O composition, preparation method is the same as embodiment 1, with dilute H 2 SO 4 Or dilute NaOH solution to adjust the pH va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com