Quick energy-saving gas soft nitriding method for automobile tire mould

A technology for tire molds and automobile tires, which is applied in the direction of solid diffusion coating, coating, metal material coating technology, etc., can solve the problems that affect the production efficiency of tire molds, long nitriding process cycle, and more exhaust emissions, etc., and achieve good results Social benefits and environmental protection benefits, shortening the nitriding process cycle, and reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Embodiment: A kind of fast and energy-saving gas nitrocarburization method of automobile tire mold

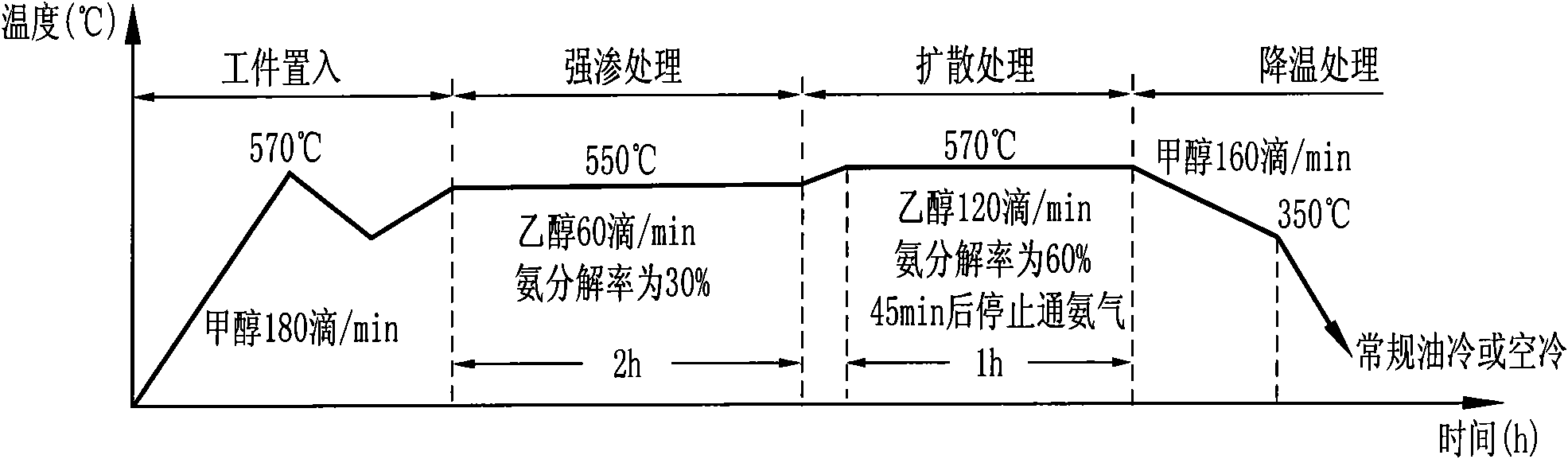

[0027] refer to figure 1 , proceed as follows:

[0028] 1), Tire mold nano treatment:

[0029] A booster system is added to the ordinary shot peening equipment, and the surface of the steel tire mold is nano-treated by the pressurized shot peening method. 0.80wt% Mn, ≤ 0.2wt% Cr, ≤ 0.30wt% Ni, ≤ 0.25wt% Cu tire mold is placed in the feed tray of the shot blasting equipment with booster system, the pressure of the booster system is 0.3MPa, The rotating speed of the tray is 15r / min, the diameter of the sprayed martensitic stainless steel shot is 1.0mm, the injection pressure of the steel shot is 0.5MPa, the spray gun swings continuously along the cavity axis of the tire mold at ±45°, and the cavity surface of the module is facing The spray gun of the shot peening device, the shot peening process is carried out on the cavity surface of the tire mold, the distance from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com