Washing dryer

A washing-drying and drying technology, which is applied to washing devices, household clothes dryers, washing machines with containers, etc., can solve the problem of compressor work obstruction, large amount of liquid refrigerant and oil return, and inability to ensure the oil level of the compressor, etc. problems, to achieve the effect of suppressing performance degradation and preventing poor work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

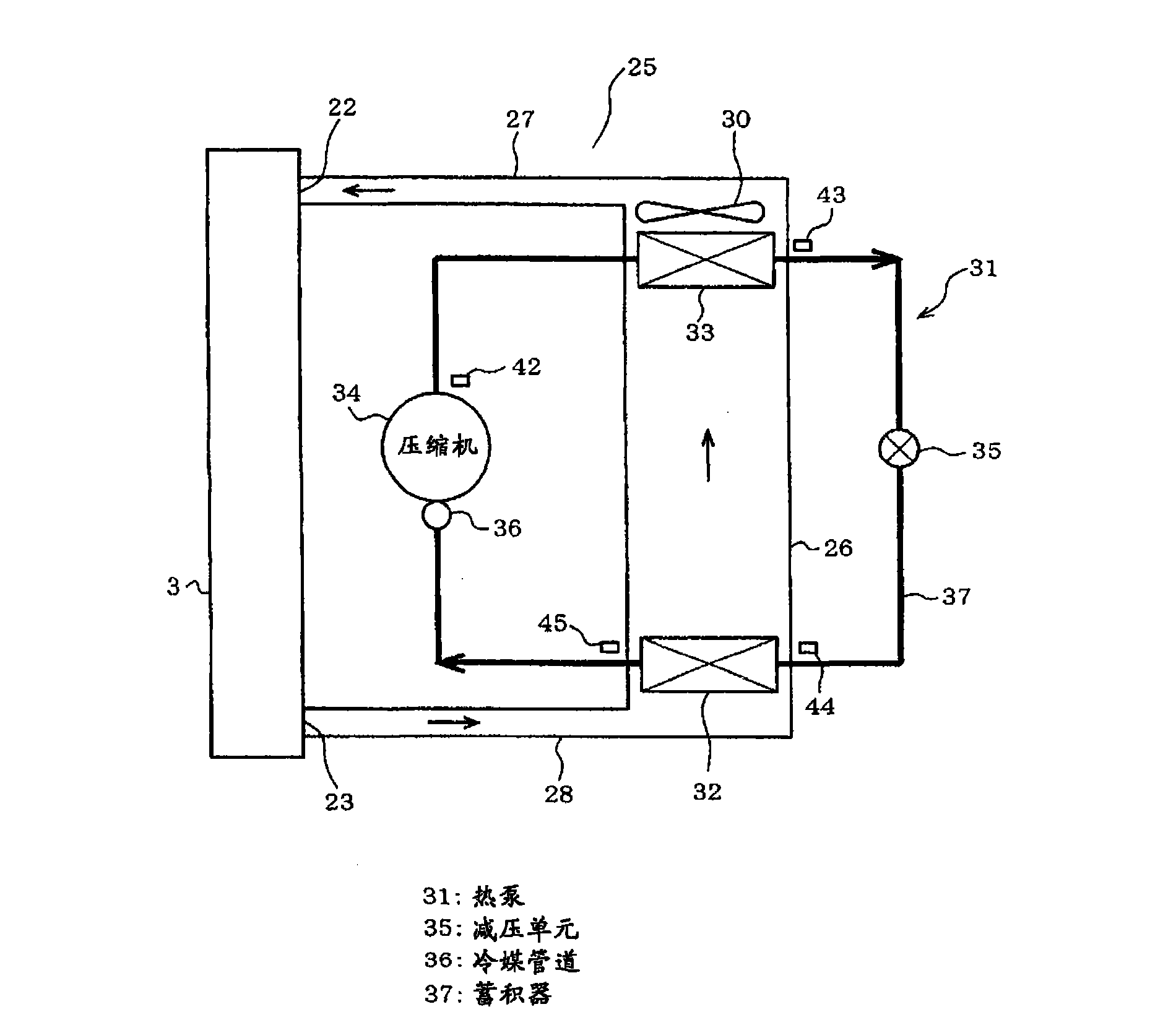

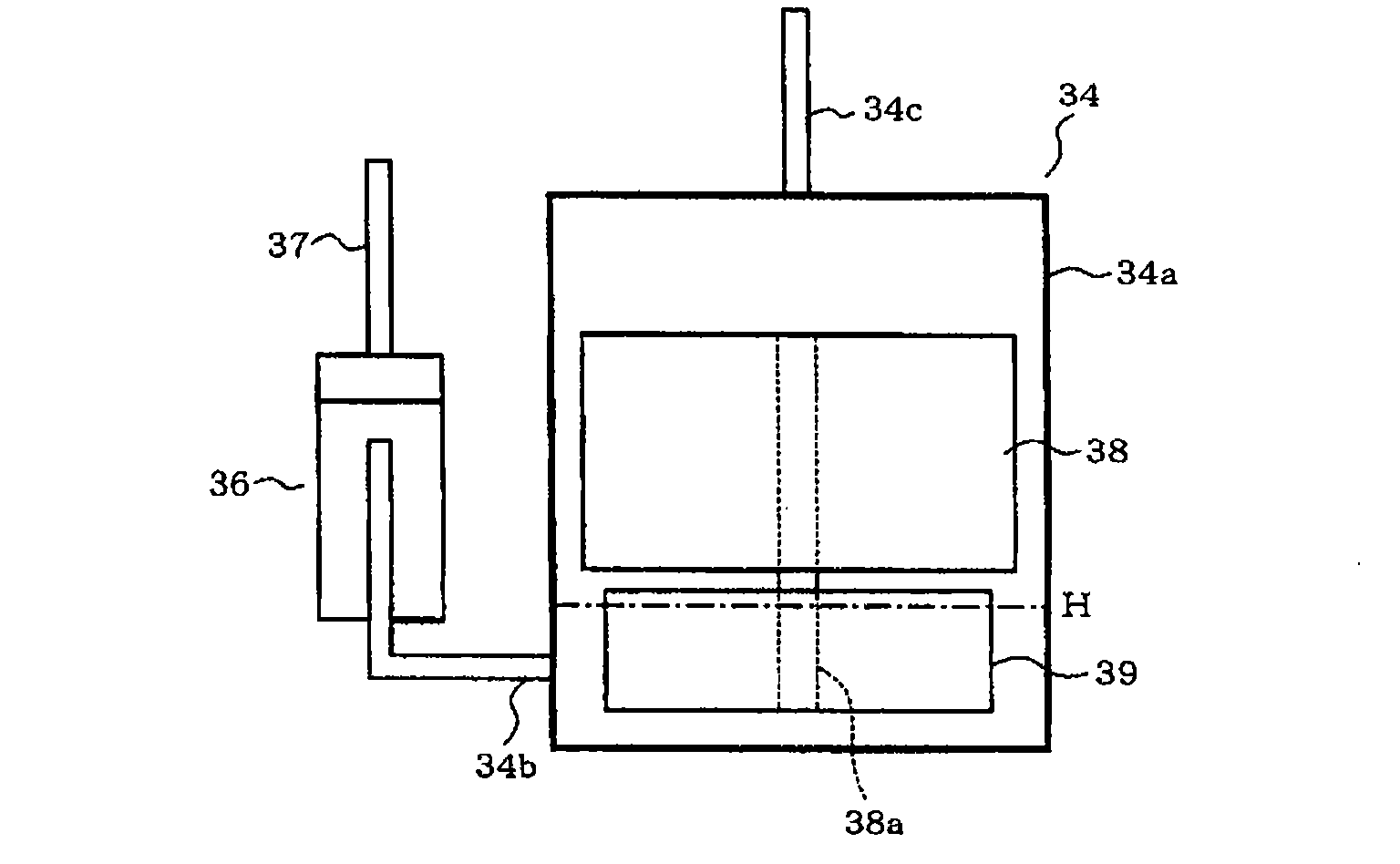

[0029] (1) The first embodiment

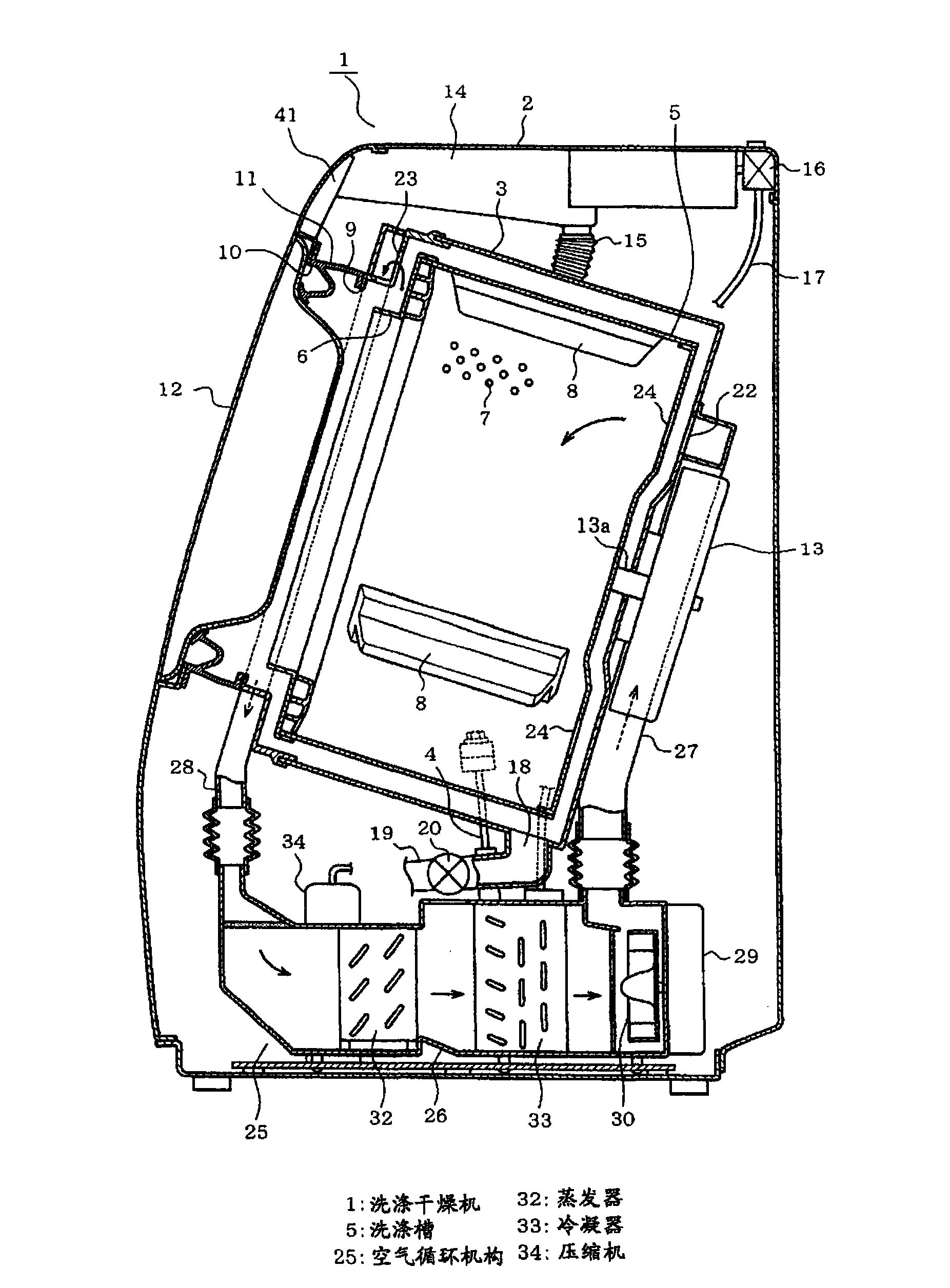

[0030] Hereinafter, with regard to the first embodiment in which the present invention is applied to a drum type washing and drying machine, refer to Figure 1 to Figure 6 while explaining. figure 1 , schematically shows the overall configuration of the drum-type washing and drying machine 1 in this embodiment. Here, inside the casing 2 of the washing and drying machine 1, the cylindrical water tank 3 is supported by an elastic support mechanism 4 (only part of which is shown) in a state inclined from front to back.

[0031] In addition, a cylindrical rotating tank (drum) 5 is rotatably supported in the water tank 3 . The rotary tank 5 rotates about an inclination axis extending in the front-rear direction of the water tank 3 and inclined from a high front to a low rear. In the front part of this rotary tank 5, the opening part 6 which takes in and puts in and out of laundry is provided.

[0032] A plurality of holes 7 (only part of which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com