Rotary fuel-feed pump for diesel engine

A diesel engine and rotor-type technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems that the performance cannot meet the high-pressure fuel combination pump, the output performance limitation of the medium used, and the high-pressure fuel combination pump cannot meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

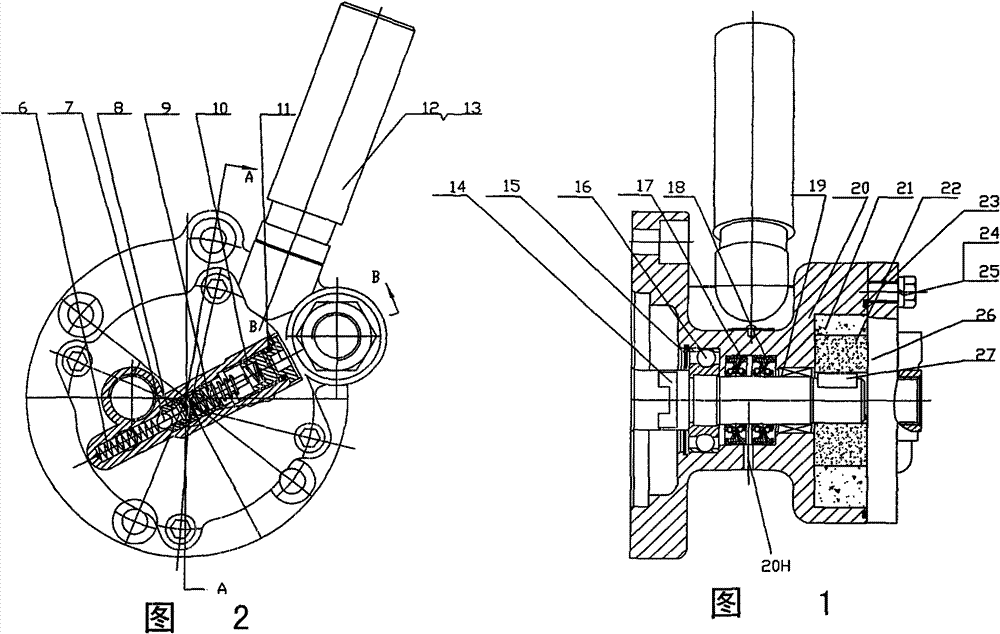

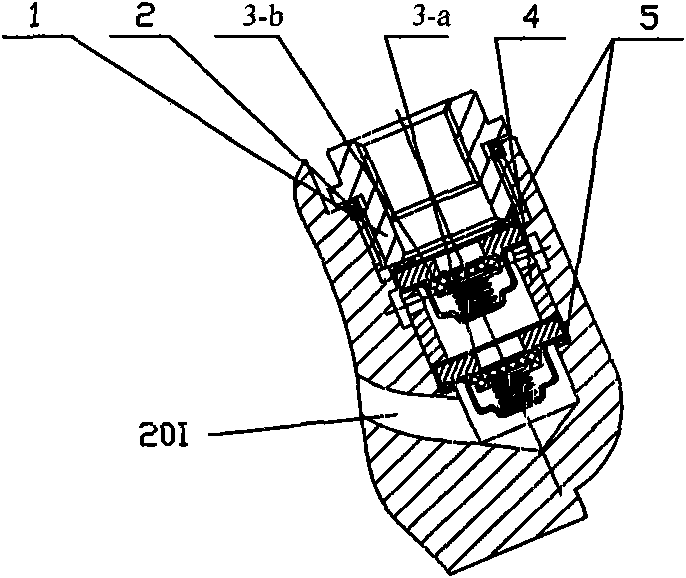

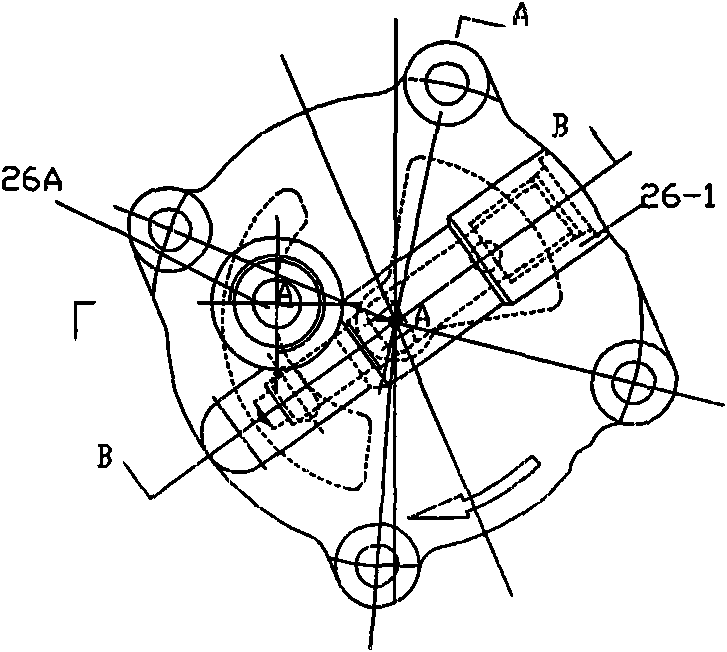

[0024] The basic structure of the diesel engine rotor type fuel delivery pump in this embodiment is as follows: figure 1 , figure 2 and image 3 shown. In the figure, 1 is the oil inlet screw sleeve, 2 is the sealing ring, 3-a and 3-b are the combined valve components, 4 is the spacer ring, 5 is the composite washer, 6 is the one-way valve spring, 7 is the steel ball, 8 is the Relief valve, 9 is the spring of the relief valve, 10 is the plug of the relief valve, 11 is the sealing ring, 12 is the gasket, 13 is the hand pump, 14 is the transmission shaft, 15 is the elastic retaining ring, 16 is the centripetal Ball bearings, 17 and 18 are double-lip skeleton oil seals, 19 is a needle roller bearing, 20 is a pump body, 21 is an outer rotor, 22 is an inner rotor, 23 is a sealing ring, 24 is a bolt, 25 is a circlip, 26 Is an end cap, and 27 is a flat key.

[0025] The same hand pump 13 as the prior art is housed on the pump body 20, the transmission shaft 14 of external power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com