Screw type refrigerating compressor for ship

A refrigeration compressor and screw-type technology, applied in the field of compressors, can solve the problems of non-adjustable internal pressure volume ratio, small application range, and small cooling capacity, so as to increase the application range, ensure normal operation, and increase cooling capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

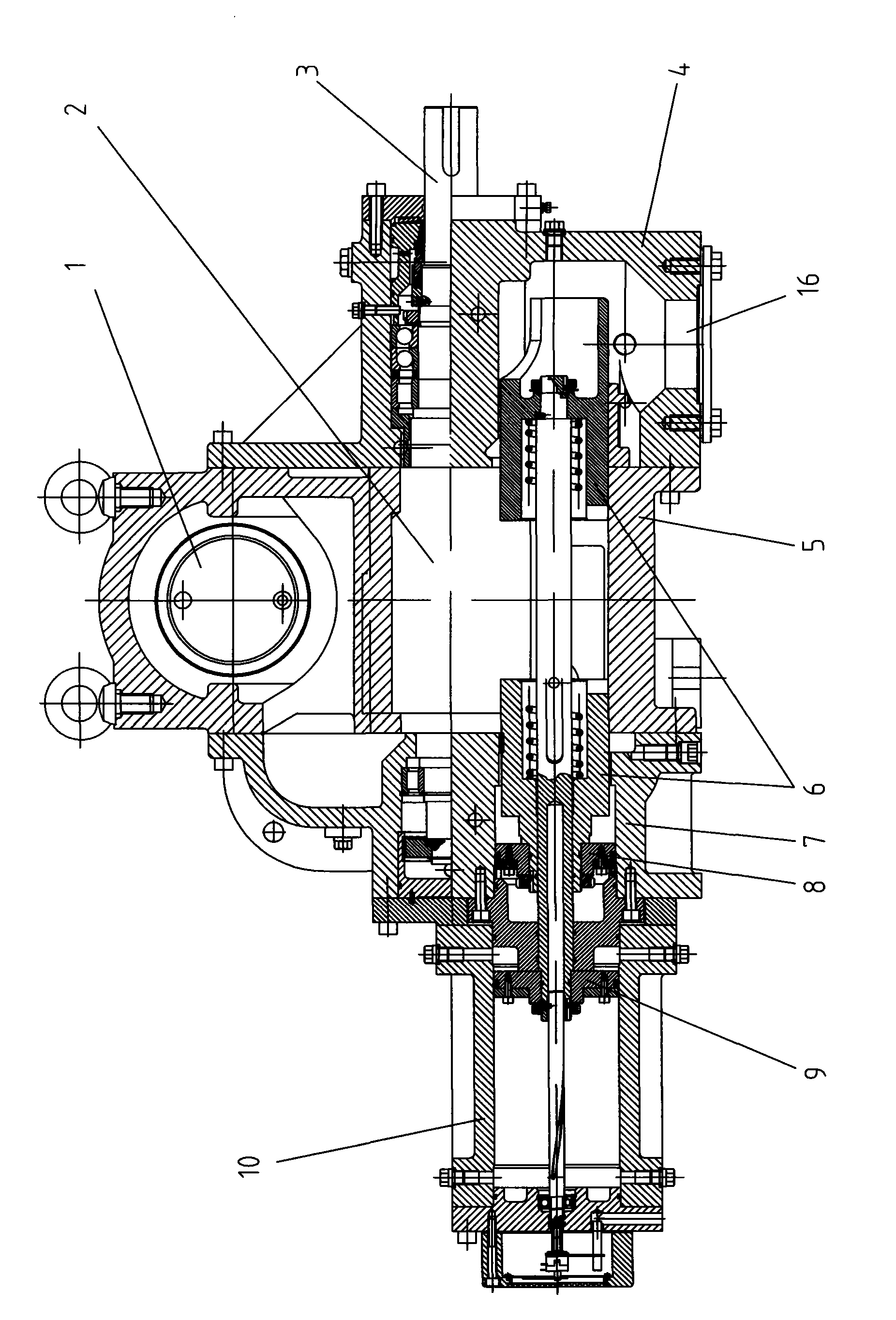

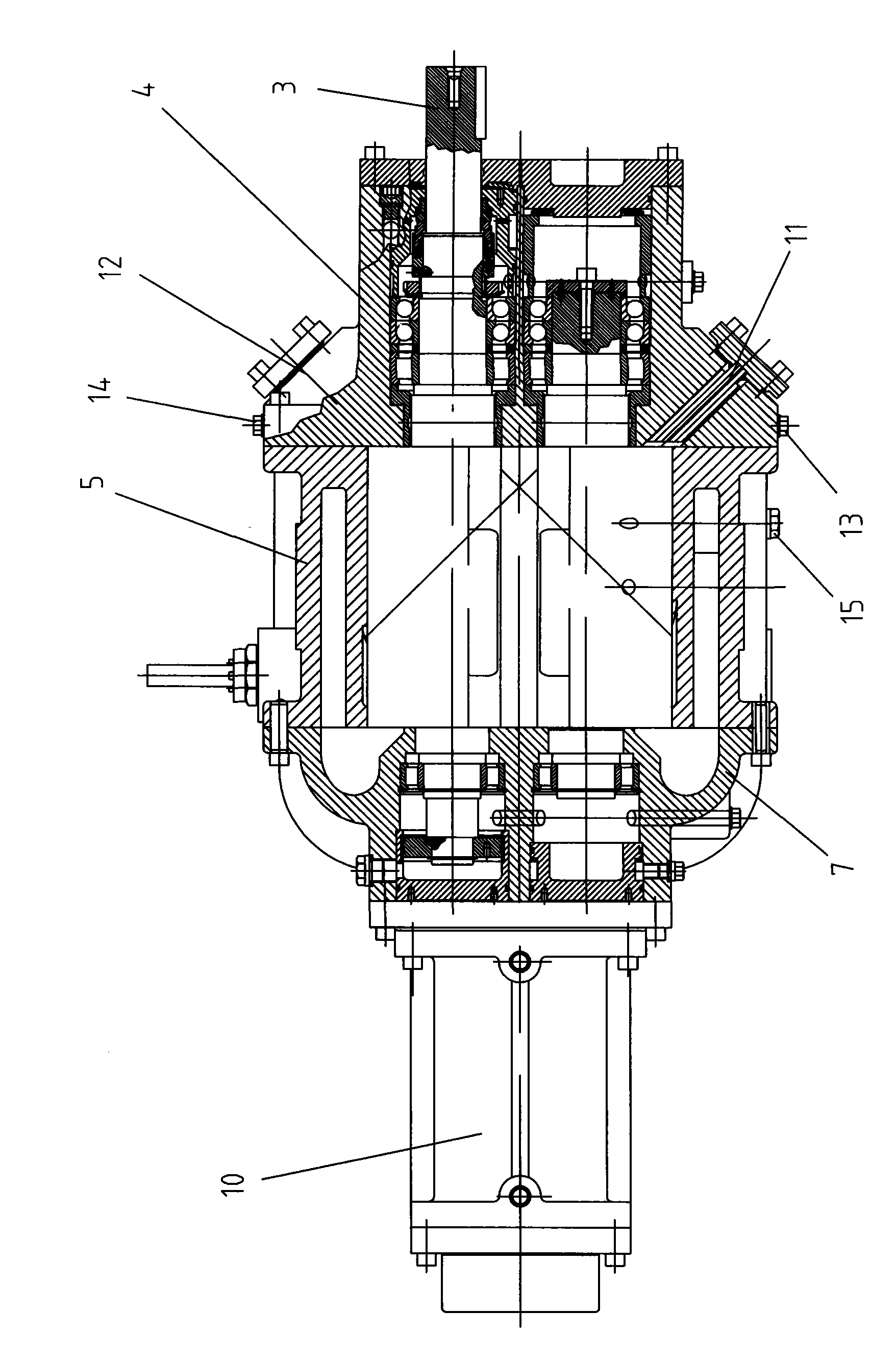

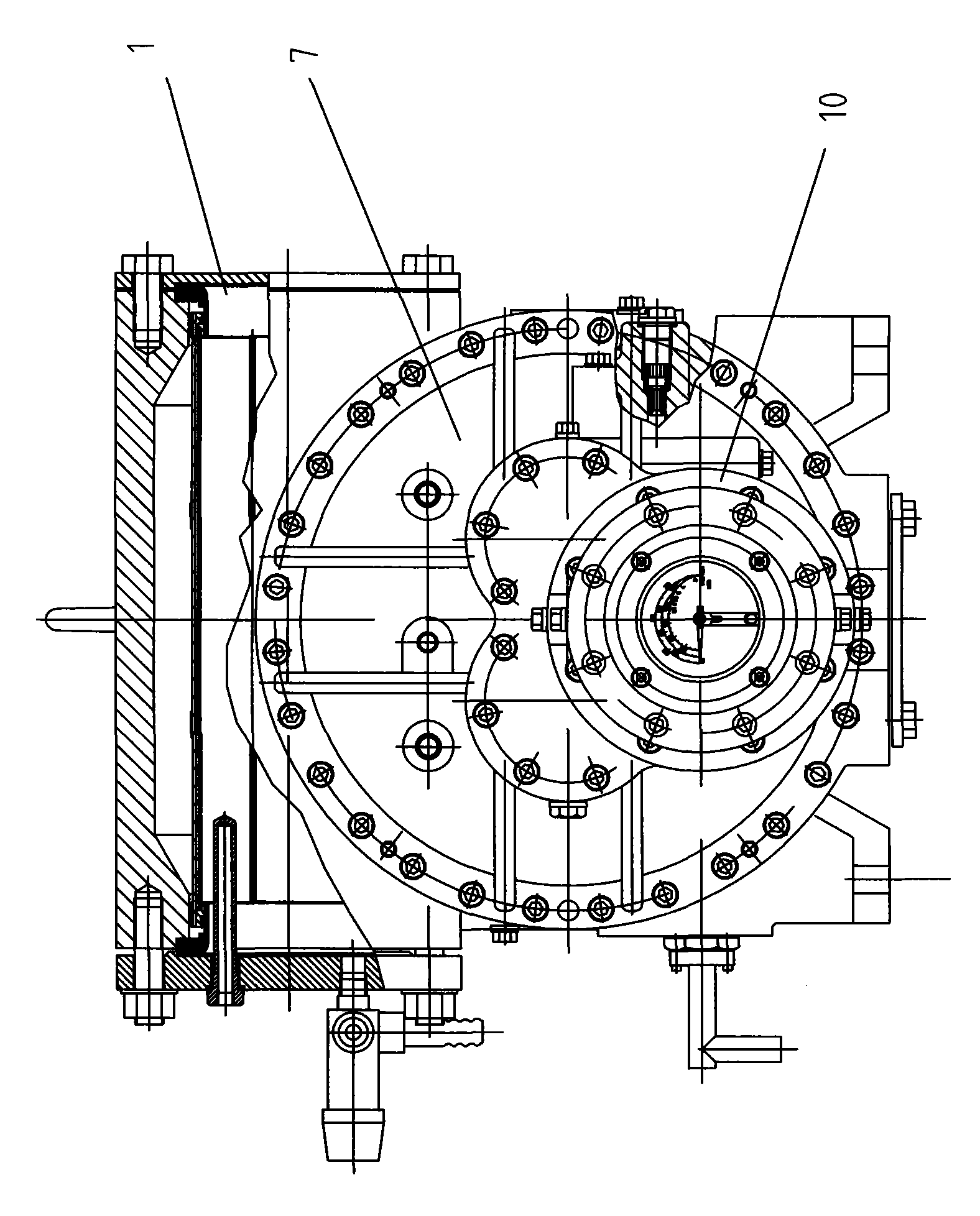

[0011] Such as figure 1 , 2 , shown in 3: 5 is an intermediate body, 4 is an exhaust end seat, and 7 is an air suction end seat, which are fixedly connected by bolts to form a body. 2 are twin-screw rotors arranged parallel to each other, and each rotor is supported on the machine body through bearings. A regulating cylinder 10 connected with the hydraulic control device is fixedly connected to the suction end seat 7, and a regulating valve group is formed in the body through a piston 9, two pistons 8 and regulating valve body 6 matched with the regulating cylinder 10, for Regulatory control of the entire compressor. The suction port 1 is provided above the intermediate body 5 . An exhaust port 16 is provided below the exhaust end seat 4 .

[0012] The body is processed with an air supply port 11 for high-temperature working conditions and an air supply port 12 for low-temperature working conditions. Each air supply port communicates with the compression chamber inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com