Rotor punching sheet of double-cage induction motor

A technology of induction motor and rotor punching, which is applied to asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of large starting current and low starting torque, achieve simple structure, obvious effect, and improve starting performance. and work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

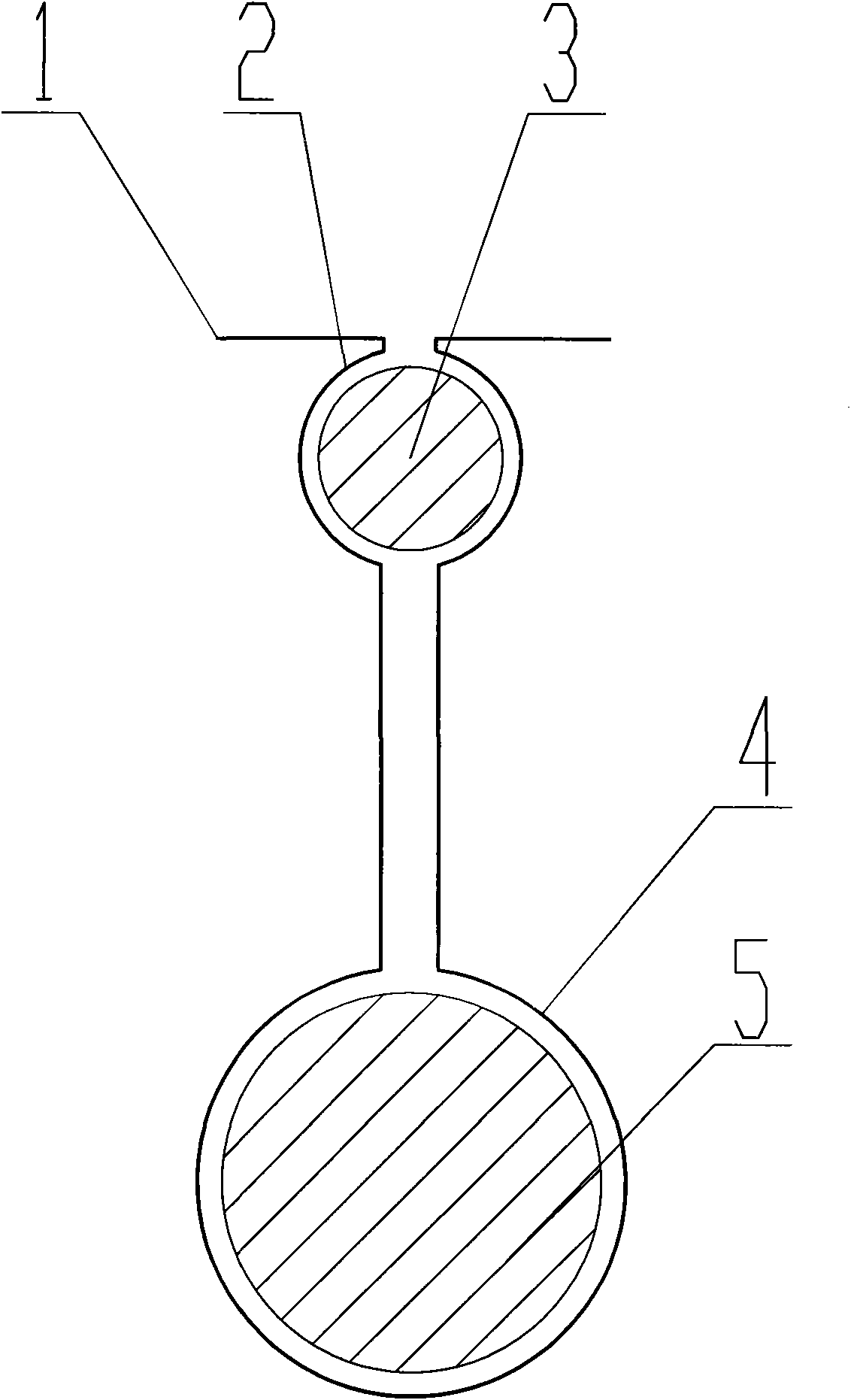

[0013] Such as figure 1 As shown, it includes rotor punch body 1, starting cage slot 2, upper cage guide bar 3, working cage slot 4, lower cage guide bar 5, and the rotor punching body 1 punches starting cage slot 2 and working cage slot 4. The upper cage guide bar 3 and the lower cage guide bar 5 are respectively put into the starting cage slot 2 and the working cage slot 4 to form two sets of mutually independent upper and lower cage windings. The upper and lower cage windings can be independent of each other or have common end ring.

[0014] Two sets of cage-shaped windings are arranged on the punched body of the rotor in the present invention, and the upper and lower cage-shaped windings can be independent from each other or have a common end ring. Under the same bar current, the leakage flux of the lower cage winding is much more than that of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com