Method for preparing a fire retardant additive for coatings and resulting products

A technology of flame retardant additives and additives, applied in the direction of nanotechnology for materials and surface science, fire-resistant coatings, chemical instruments and methods, etc., to achieve the effect of controlling smoke emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

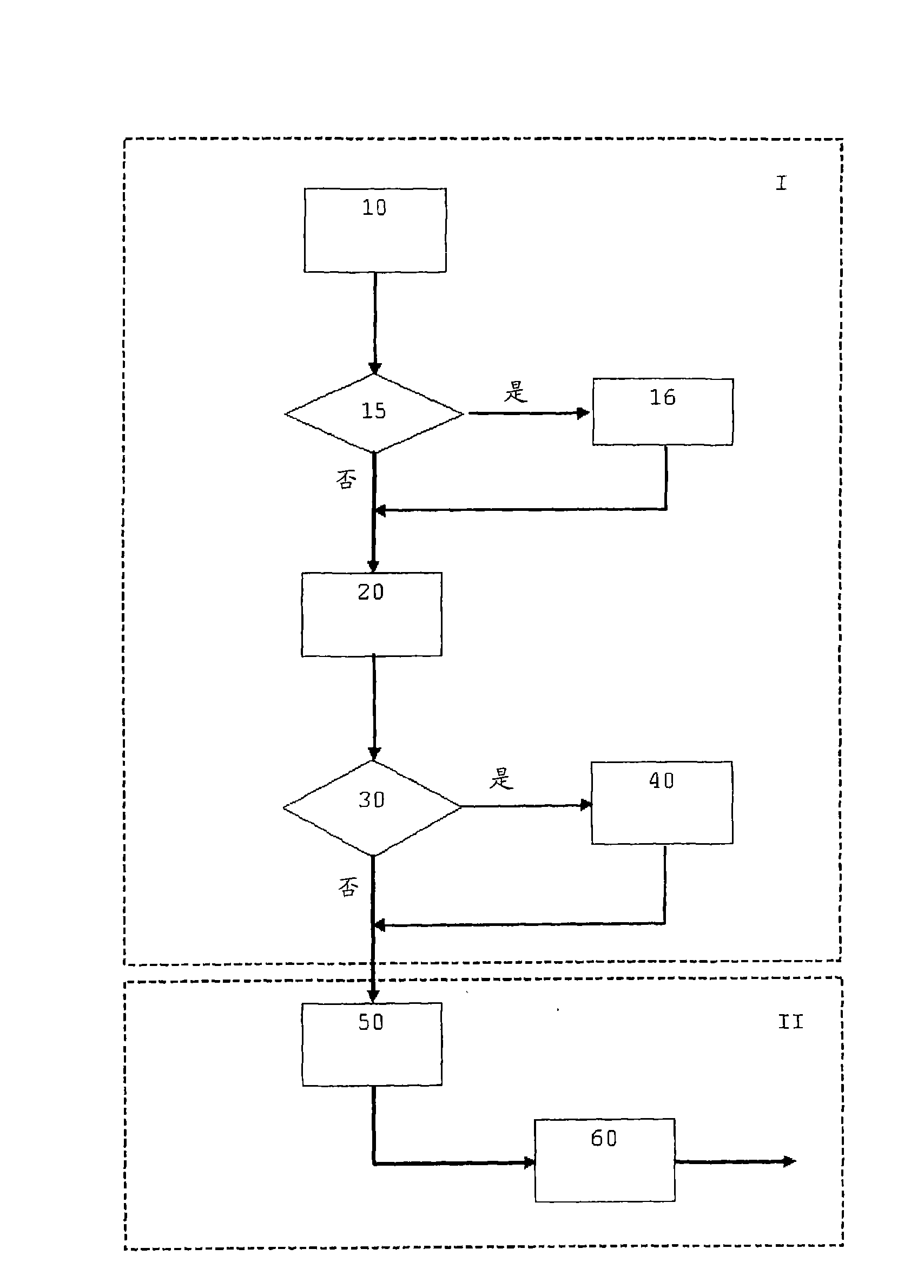

Method used

Image

Examples

Embodiment 1

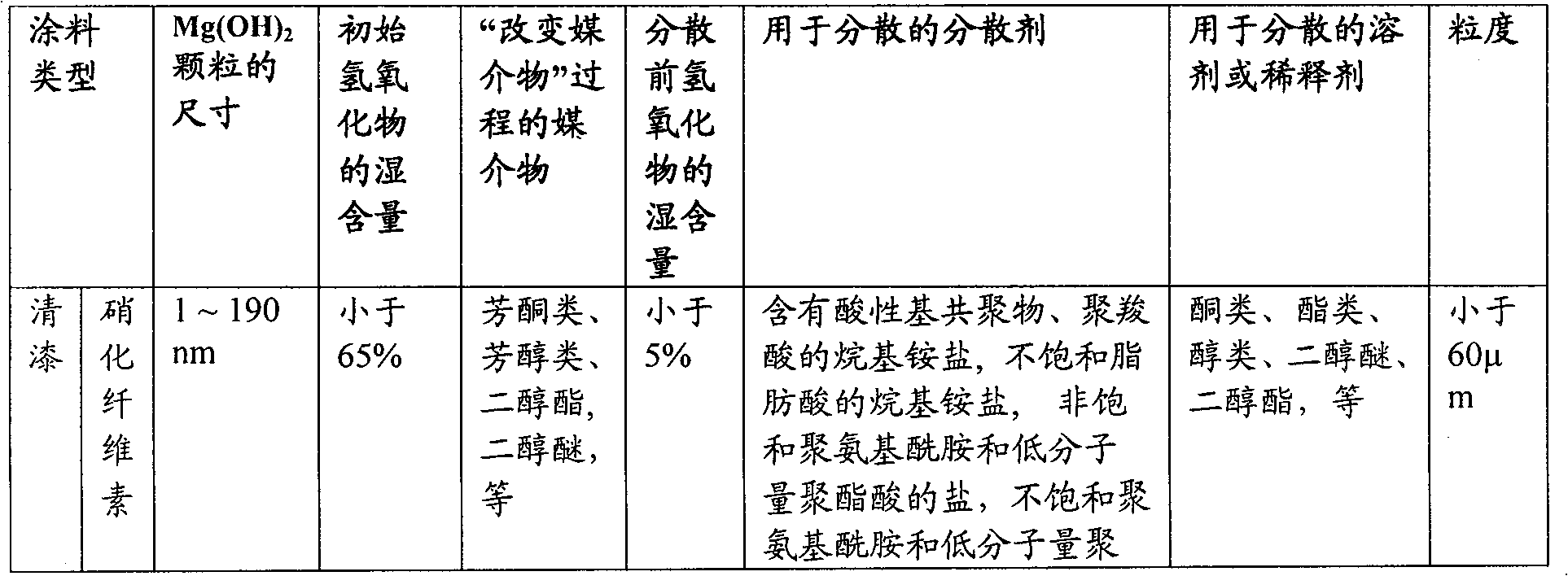

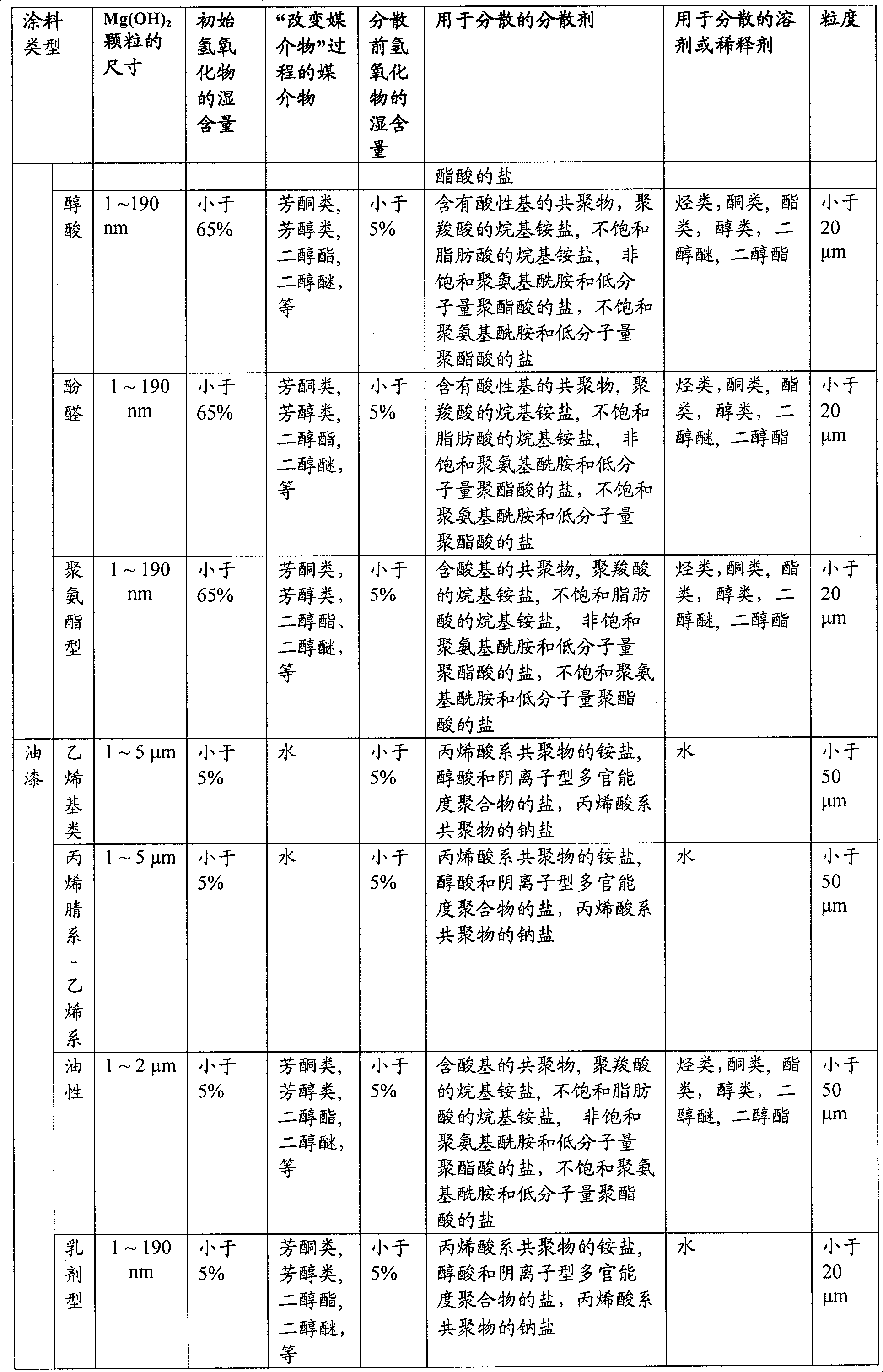

[0061] Embodiment 1 is used for the preparation of the additive in the alkyd type coating that residual moisture content is less than 5%

[0062] 1. Separation of nano-scale magnesium hydroxide having the following particle size distribution with a moisture content of 65%: D 10 , 59.0nm; D 50 , 92.7nm; D 90 , 153 nm; measured by laser ray scattering using equipment designated COULTER LS 230. For telling purposes, we use 1200 grams.

[0063] 2. Place the magnesium hydroxide granules in a 6L container with a pour spout.

[0064] 3. Pour 3600 g of ethylene glycol butyl ether, and agitate (disperse) at a peripheral speed of 5 to 30 m / s using a dispersing propeller. This agitation (dispersion) is maintained for 5 to 15 minutes.

[0065] 4. Remove as much of the liquid fraction as possible with the help of a centrifuge, decanter, filter or other means of solid-liquid separation, depending on the capabilities of the separation equipment chosen.

[0066] 5. Repeat steps 3 and 4 ...

Embodiment 2

[0076] Example 2: Preparation of additives for use in nitrocellulose-based coatings with a residual moisture content of less than 5%

[0077] 1. Charge 490 grams of nitrocellulose into a non-spout 1.0 L Berzelius beaker.

[0078] 2. Place the beaker in a dispersing device with a diameter of 7 cm and a deflector and a propeller for dispersing.

[0079] 3. Agitate the resin at a moderate speed.

[0080] 4. Pour 10 grams of resin-compatible dispersant DCM-305 (a copolymer containing acid groups).

[0081] 5. Add 400 grams of dry magnesium hydroxide with an average particle size of 100 nm.

[0082] 6. Maintain moderate agitation until the magnesium hydroxide is completely wetted.

[0083] 7. After mixing evenly, increase the speed of the disperser until it has sufficient shear force to ensure effective dispersion: the peripheral speed is 15-30m / s.

[0084] 8. Leave to diffuse for 15 minutes or as long as needed to achieve application granularity.

[0085] The flame retardant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com