Production method for promoting quality of cooled fresh-keeping beef

A production method, beef technology, applied in the direction of freezing/cooling preservation of meat/fish, heating preservation of meat/fish, preservation of meat/fish with chemicals, etc., can solve the problem of darkening of color in vacuum anaerobic environment, cooling meat processing rate Less than 5% and other problems, to achieve the effect of reducing the generation of harmful substances, reducing the production of DFD meat, and reducing stress response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

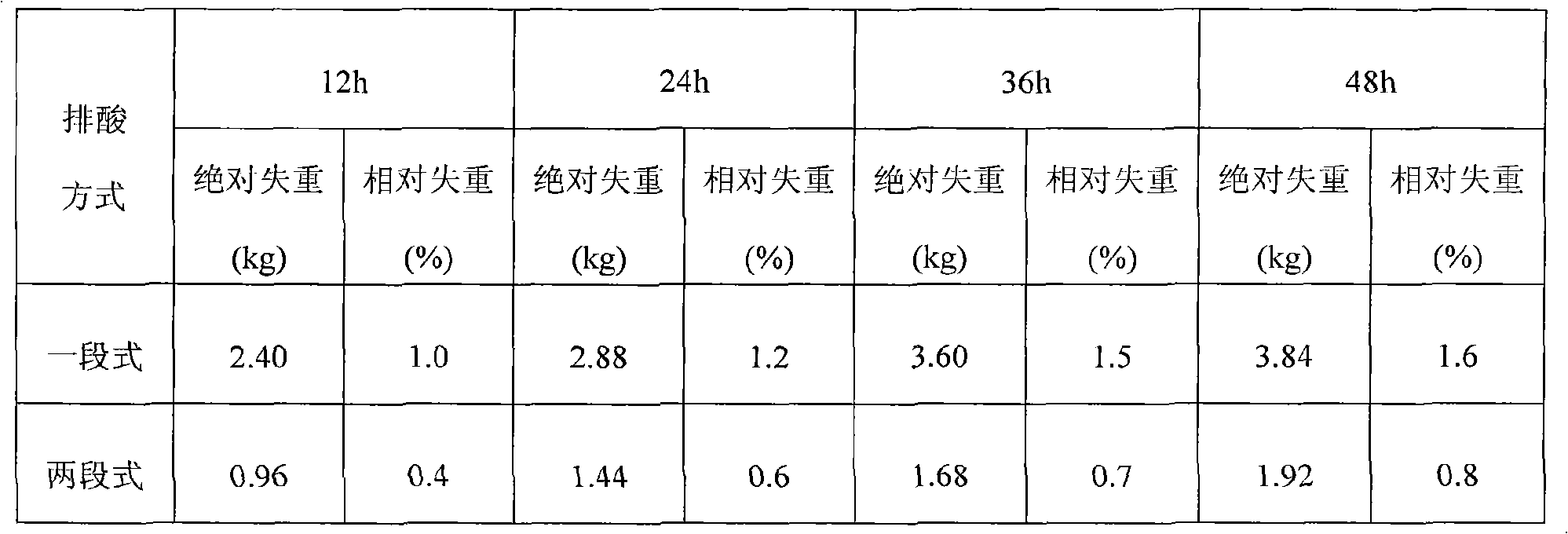

Image

Examples

Embodiment

[0025] 1. Implement animal welfare

[0026] This method combines five standards to ensure animal welfare, that is, freedom from hunger and thirst; freedom from comfort; freedom from pain, injury and disease; freedom from fear and sadness; freedom from expressing nature. Freedom can reduce the stress response of beef cattle due to slaughter and improve the quality of beef. As required, animal welfare control procedures are developed:

[0027] In the beef cattle fattening plant, feed the cattle according to the above requirements to ensure the nutrition of the feed and clean water. Animals are protected from physical injury, and they can move freely in the activity field for more than 2 hours a day. The corrals used during transportation and the chute for loading cattle are fully considered to prevent cattle from being crowded and slipping.

[0028] The cattle unloading platform and the ground on which the cattle walk should be non-slip to ensure sufficient water for the fatte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com