Carbon dioxide removal system

a carbon dioxide and removal system technology, applied in the direction of liquid degasification by filtration, membranes, other medical devices, etc., can solve the problem that the extracorporeal blood treatment system does not have a heat exchanger adaptabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

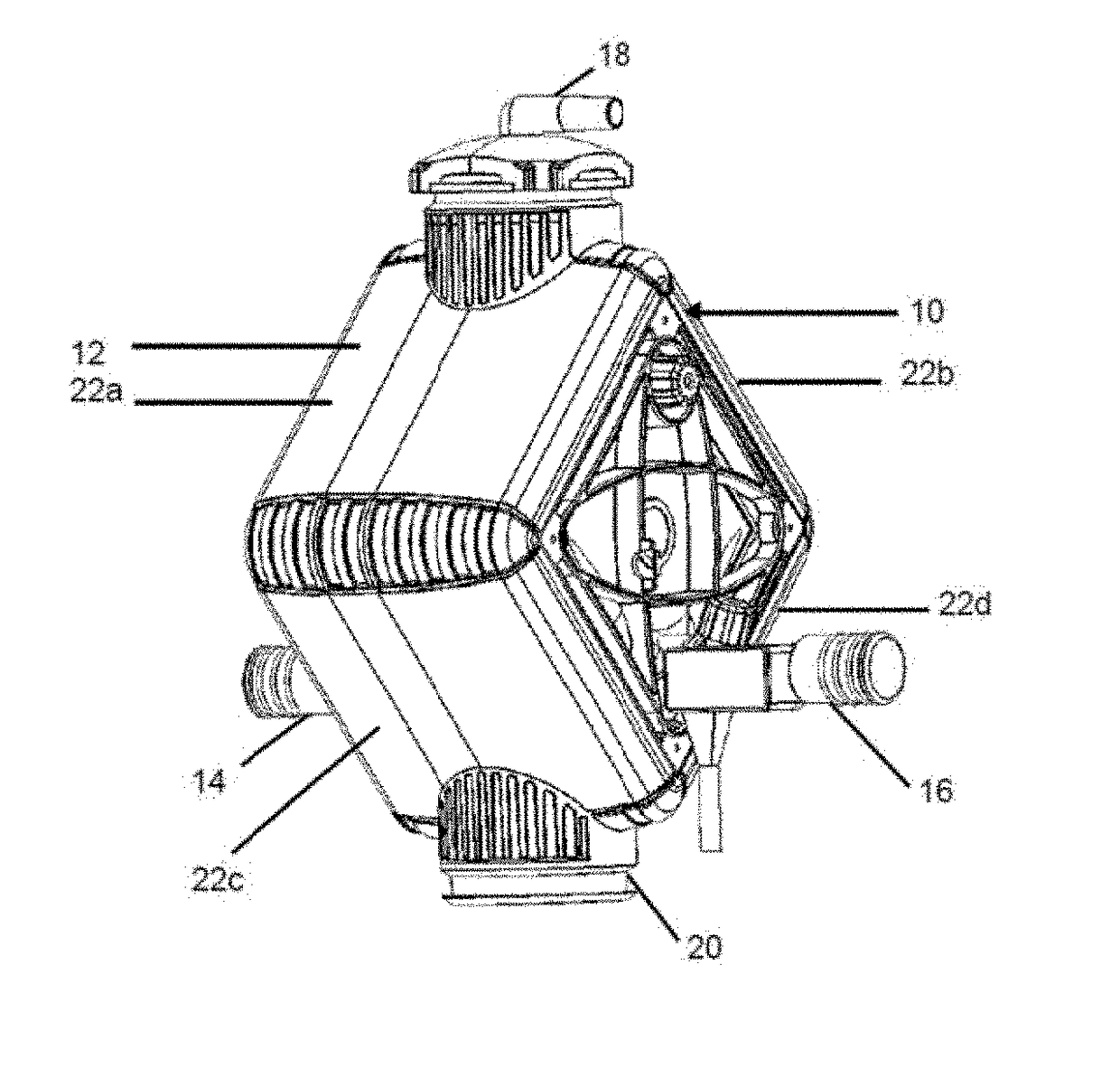

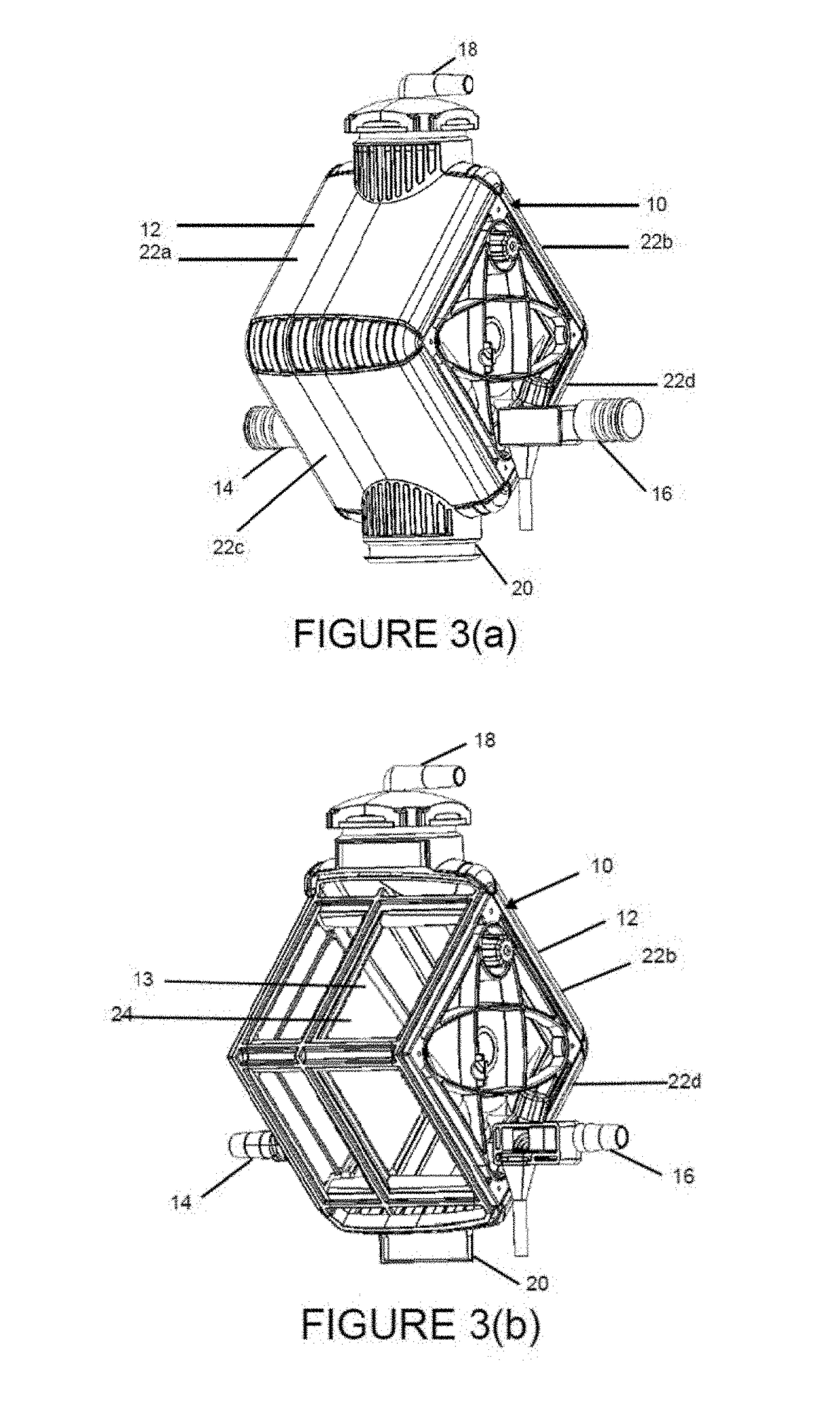

[0128]In one embodiment, gas exchange module 10 of the present invention has the same configuration as shown in FIGS. 3(a)-3(b), 3(d)-3(f) and 3(h)-3(m). Gas exchange module 10 included a gas exchange mat 34 constructed from 13,834 or more microporous gas permeable conduits 30 adapted for carbon dioxide diffusion. Conduits 30 were positioned parallel to one another to form conduit layers 32. The conduit layers 32 were stacked on top of one another to form gas exchange mat 34, each layer oriented perpendicular to an adjoining layer. All of the conduits 30 had an active length of about 5.5 cm and a total conduit length of about 7.6 cm. The active length percentage of conduit 30 capable of gas transfer was at most about 72.4%. Gas exchange mat 34 had a total gas exchange surface area of about 0.98 m2 and a conduit density of about 14,116 conduits per m2. The ratio of a maximum conduit active length to the 5.4 cm thickness of the gas exchange mat 34 (which can also be expressed here as ...

example 2

[0129]In one embodiment, gas exchange module 10 of the present invention has the same configuration as shown in FIGS. 3(a)-3(b), 3(d)-3(f) and 3(h)-3(m). Gas exchange module 10 included a gas exchange mat 34 constructed from 13,119 or more microporous gas permeable conduits 30 adapted for carbon dioxide diffusion. Conduits 30 were positioned parallel to one another to form conduit layers 32. The conduit layers 32 were stacked on top of one another to form gas exchange mat 34, each layer oriented perpendicular to an adjoining layer. All of the conduits 30 had an active length of about 5.8 cm and a total conduit length of about 7.6 cm. The active length percentage of conduit 30 capable of gas transfer was at most about 76.3%. Gas exchange mat 34 had a total gas exchange surface area of about 0.98 m2 and a conduit density of about 13,300 conduits per m2. The ratio of a maximum conduit active length to the 5.4 cm thickness of the gas exchange mat 34 (which can also be expressed here as ...

example 3

[0130]In one embodiment, gas exchange module 10 of the present invention has the same configuration as shown in FIGS. 3(a)-3(b), 3(d)-3(f) and 3(h)-3(m). Gas exchange module 10 included a gas exchange mat 34 constructed from 17,148 or more microporous gas permeable conduits 30 having an outer diameter of about 0.35 mm and is adapted for carbon dioxide diffusion. Conduits 30 were positioned parallel to one another to form conduit layers 32. The conduit layers 32 were stacked on top of one another to form gas exchange mat 34, each layer oriented perpendicular to an adjoining layer. All of the conduits 30 had an active length of about 5.2 cm and a total conduit length of about 7.6 cm. The active length percentage of conduit 30 capable of gas transfer was at most about 68.4%. Gas exchange mat 34 had a total gas exchange surface area of about 0.98 m2 and a conduit density of about 17,497 conduits per m2. The ratio of a maximum conduit active length to the 5.4 cm thickness of the gas exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com