Plane dust collection device

A dust removal device and plane technology, applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problems of cleaning, etc., and achieve the effect of simple structure, flexible electrode shape and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

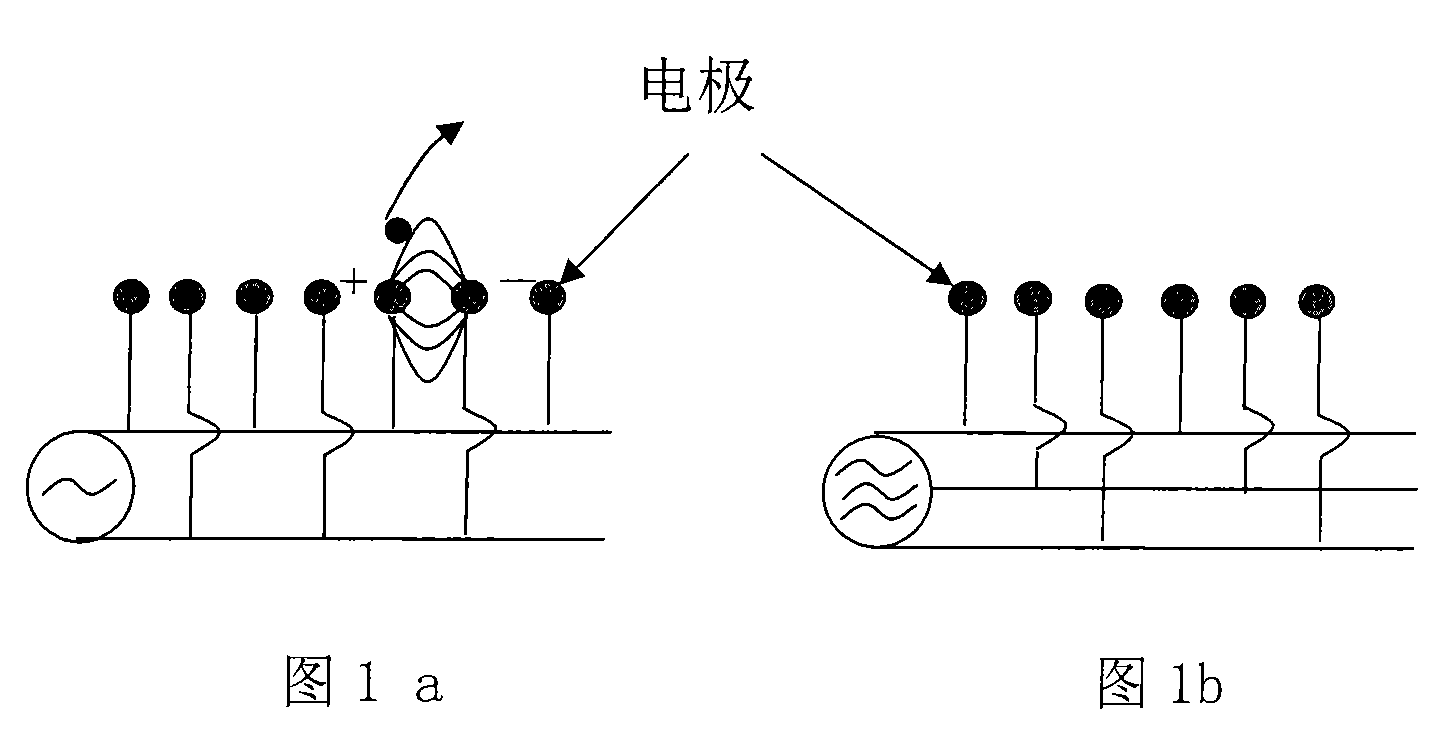

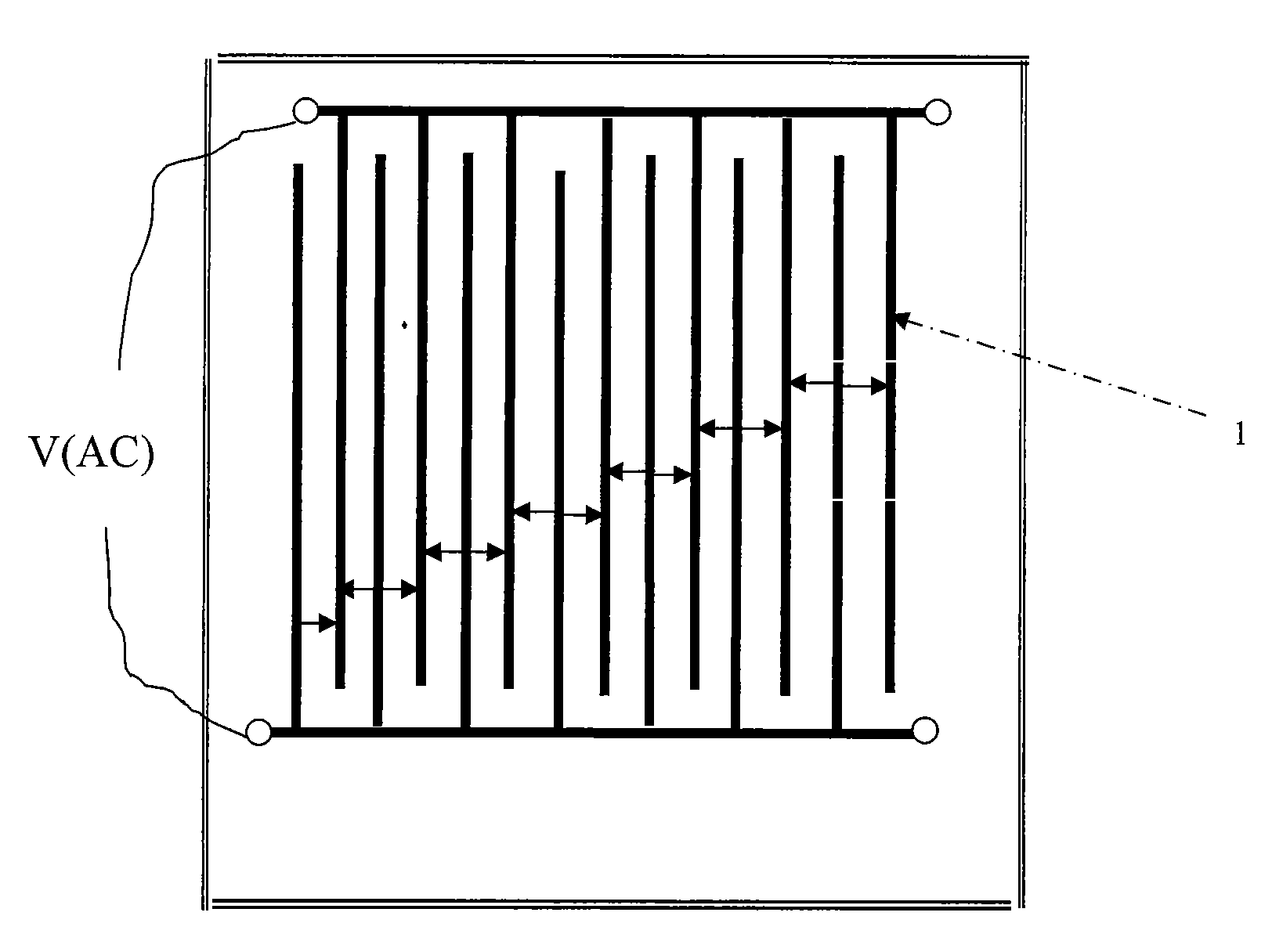

[0038] figure 2 It is a structural schematic diagram of the present invention (using comb-shaped electrodes, two-phase AC drive power supply); a pair of comb-shaped electrodes are in the same plane, and the first comb-shaped teeth 1 and the first comb-shaped teeth 2 of the pair of electrodes are opposite Placed crosswise, the cross-section width of the comb-shaped teeth is 0.1mm-1.5mm, and the spacing between the comb-shaped teeth is 0.2mm-5mm; an AC voltage of 50V-2000V (ie, the driving power V) is connected to the input end of the electrode, and the The AC voltage is a square-wave AC power source with an adjustable frequency between 50 and 500 Hz. The parallel electrodes of the planar dust removal device of this embodiment can be placed on a substrate.

Embodiment 2

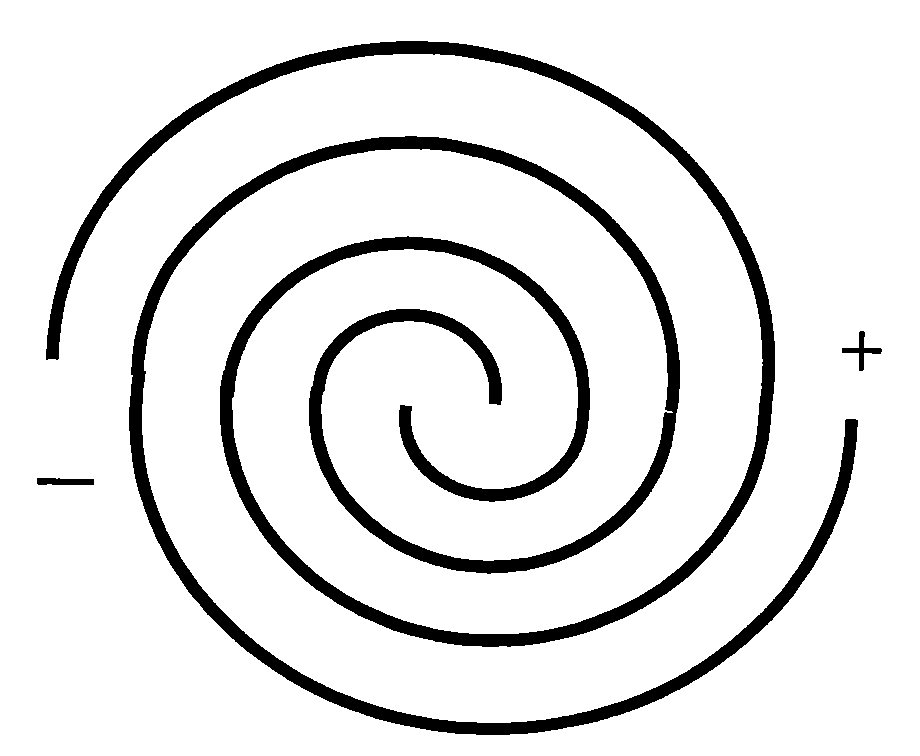

[0040] attached image 3 It is a schematic diagram of the structure of the present invention (using a spiral-shaped electrode, two-phase alternating current driving power supply); the driving power adopts two-phase electric driving, and after passing through the alternating current, the dust will be removed outside the electrode area. A pair of spiral electrodes (electrode 1 and electrode 2) are in the same plane. The two sets of spiral electrodes of the pair of electrodes are placed opposite to each other. The cross-sectional width of the spiral electrodes is 0.1mm-1.5mm, and the distance between the electrodes is 0.2mm. -5mm; a voltage of 50V to 2000V is connected to its input terminal, and the voltage is a frequency-adjustable square-wave AC power supply.

[0041] In short, as long as the parallel electrodes are covered on the surface of the equipment that needs to be dust-proof, the equipment can be kept in a dust-free environment. If transparent electrodes are used, they ...

Embodiment 3

[0044] Figure 4 It is a structural schematic diagram of the present invention (using parallel electrodes, three-phase alternating current driving power supply); its driving power is driven by three-phase electric power, and after passing through alternating current, dust will be removed outside the electrode area. Three sets of comb-shaped electrodes (electrode 1, electrode 2 and electrode 3 are in the same plane, three sets of comb-shaped teeth are placed at intervals, the cross-sectional width of the comb-shaped teeth is 0.1mm-1.5mm, and the distance between the comb-shaped teeth is 0.2 mm-5mm; a voltage of 50V-2000V (that is, a driving power supply V) is connected to its input terminal, and the voltage is a frequency-adjustable square-wave AC power supply.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com