Variable pitch transport chain

A conveying chain and variable pitch technology, which is applied in the field of conveying mechanisms and variable pitch conveying chains, can solve the problems of wasting mold materials, troublesome installation, high cost, etc., and achieve the effect of improving molding efficiency, saving mold materials, and outstanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

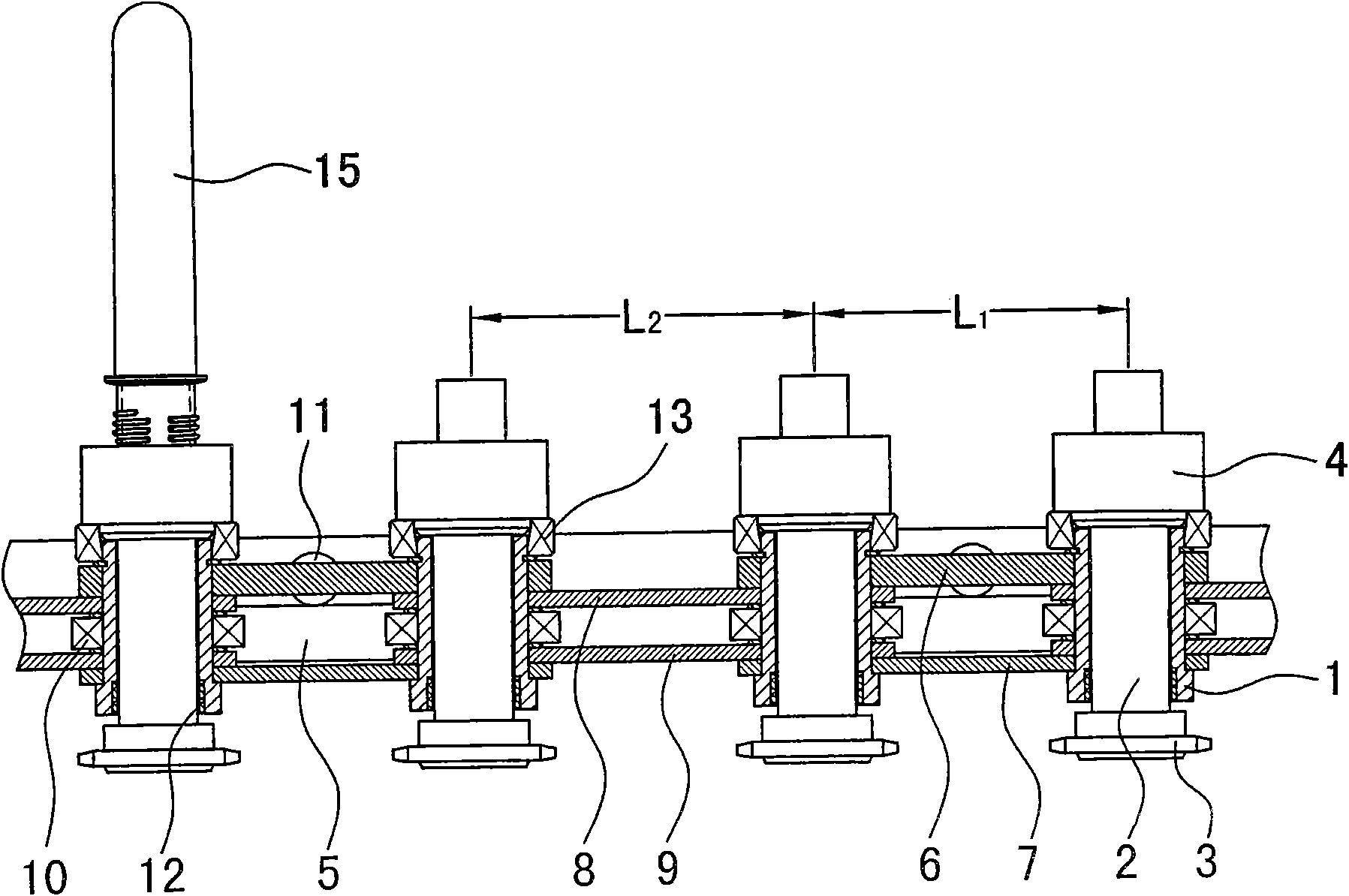

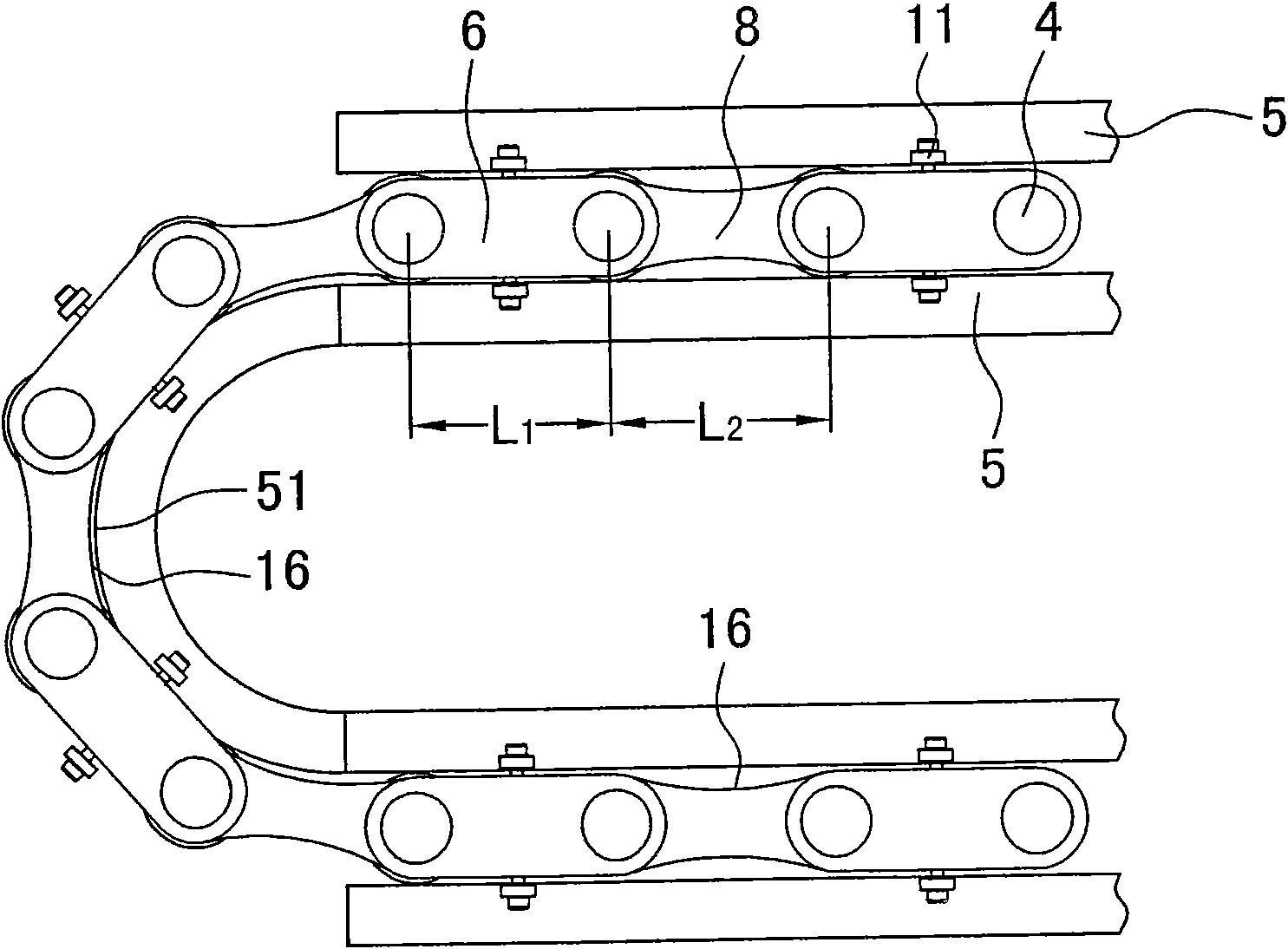

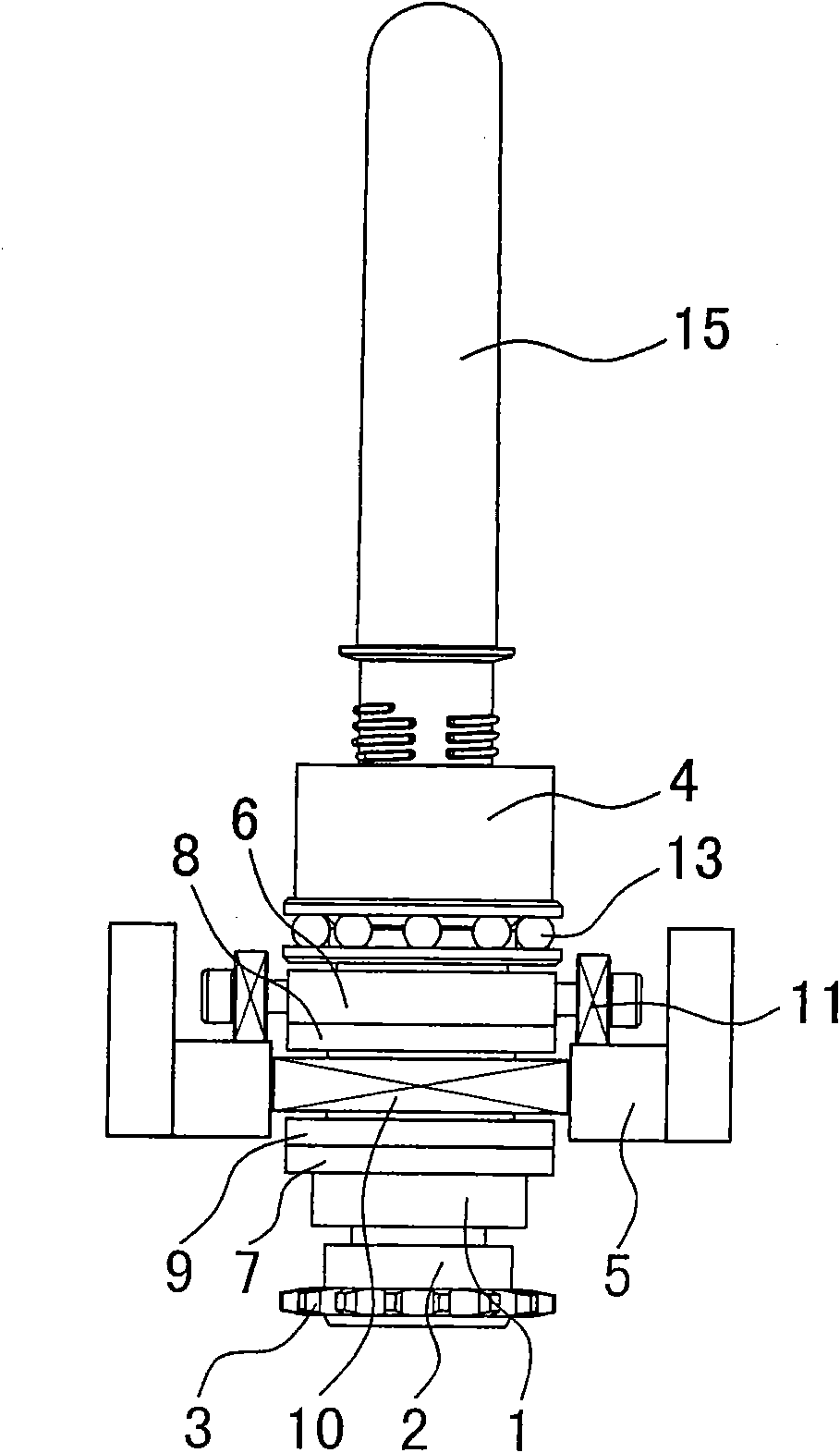

[0011] The invention discloses a variable pitch conveying chain, such as Figure 1-Figure 3 As shown, the hollow chain pin 1 is included, and each chain pin is connected by a chain plate. The hollow chain pin is equipped with a rotation shaft 2, the bottom of the rotation shaft is equipped with a rotation sprocket 3, and the upper part of the rotation shaft is equipped with a preform supporting seat 4. The preform 15 is installed on the blank supporting seat, and there are circular guide rails 5 on both sides of the conveying chain, which is characterized in that the chain links in the same stretch blowing unit group have a short pitch L 1 Less than the long pitch L of the chain link between the stretch blowing unit groups 2 , the two chain links of the short pitch are connected by the short chain plate A, B 6, 7, and the two chain links of the long pitch are connected by the long chain plate A, B 8, 9. The so-called same stretch-blowing unit group is a group of preforms form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com