Charcoal sculpture and method for making the same

A production method and technology of charcoal carving, applied in decorative art, adhesive type, decorative structure, etc., can solve the problems of small added value of products, stagnation of product shape, limited consumption, etc., to achieve radiation prevention, unique appreciation value, Health-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

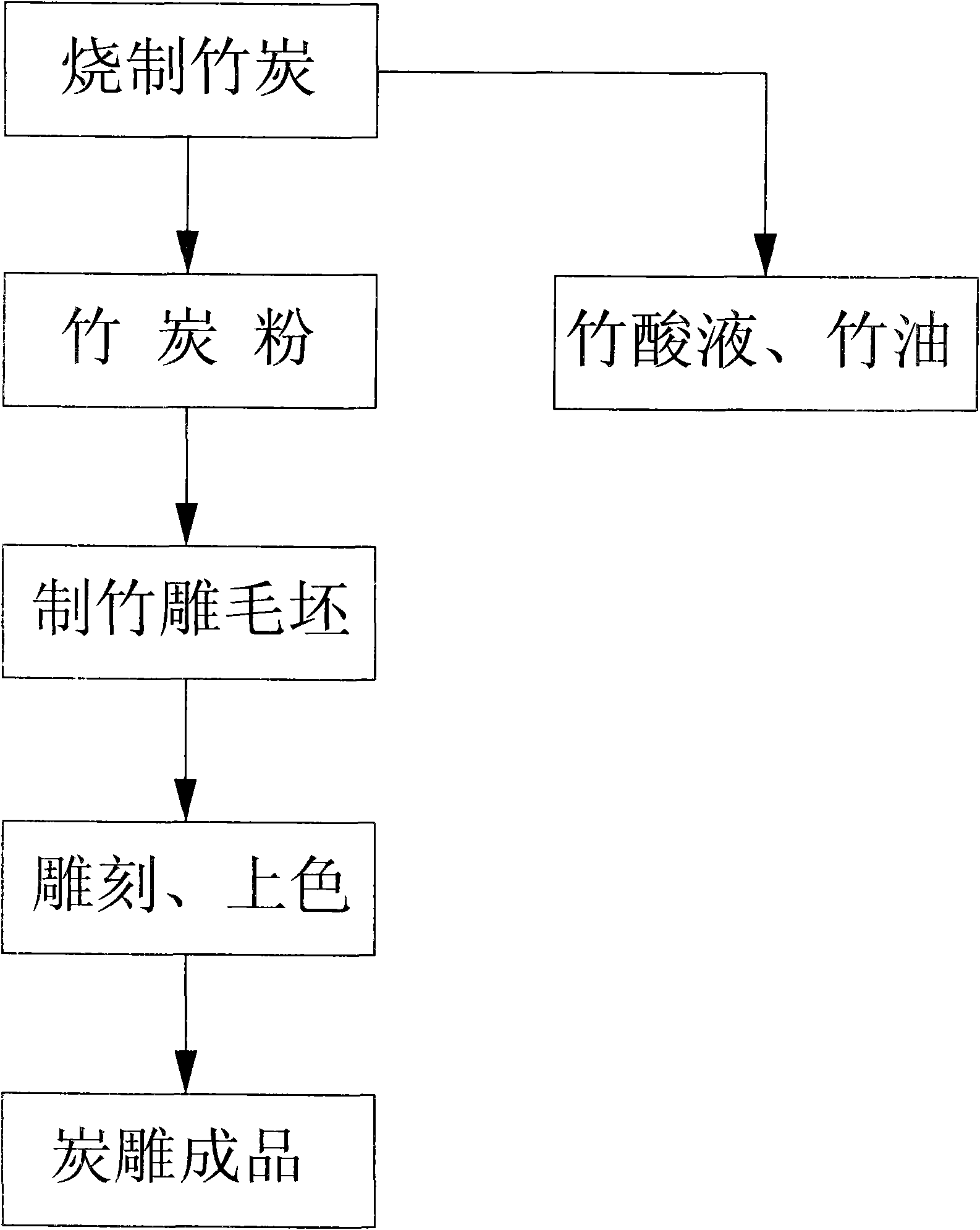

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

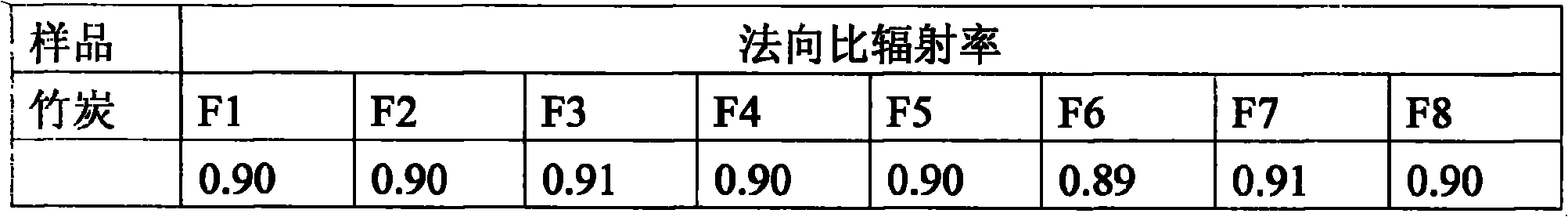

[0021] see figure 1 , a kind of charcoal carving, its main component is bamboo charcoal, and the total internal surface area of micropores in each gram of bamboo charcoal material is not less than 2000m2 2 , strength not less than 250Kg / cm 2 .

[0022] The production method of the above-mentioned charcoal carving is: firstly, bamboo charcoal is made, and bamboos with a growth period of not less than 6 years are selected as raw materials, and each bamboo is cut into several sections and put into the furnace for firing. For example, each bamboo is cut into three sections for firing. The firing time is 8 days, and the firing is continuous 24 hours a day. The carbonization temperature of firing is greater than 700°C. After firing, bamboo charcoal is obtained by cooling. The special pore shape of onion-like fullerene (C60) and expanded carbon nanotube structure co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com