Production process of environmental protection PU composite leather and formula thereof

A production process and process technology, applied in textiles and papermaking, etc., can solve the problems of large molecular particles in the dense layer, which cannot be directly removed, and are easy to stick, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

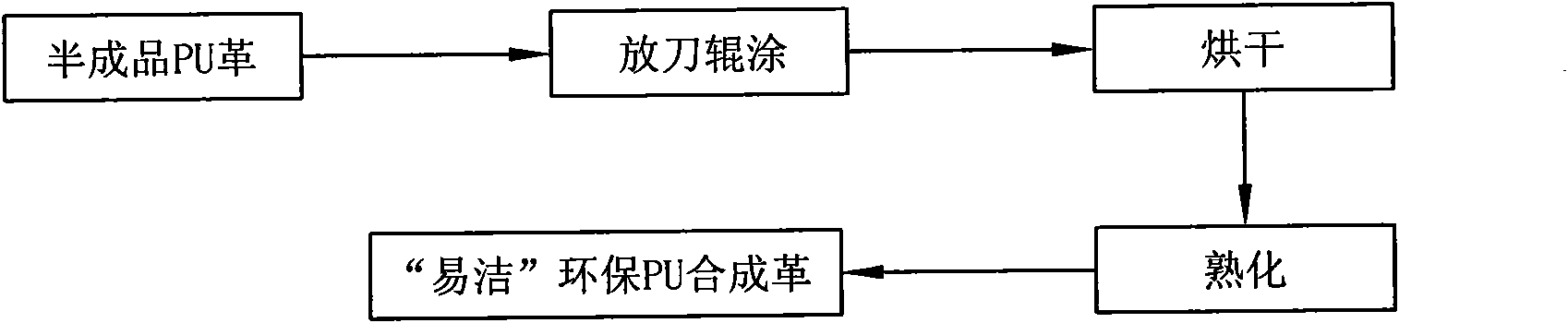

[0059] Environmentally friendly PU synthetic leather production process, the process includes:

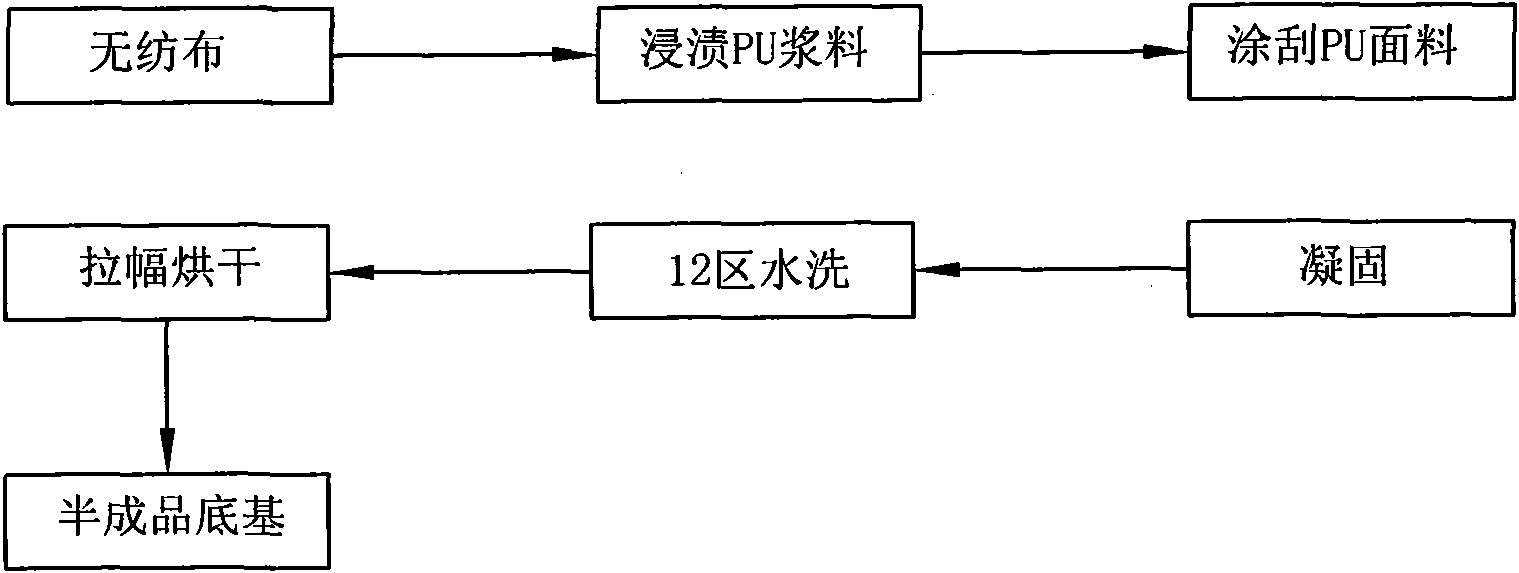

[0060] The first stage: semi-finished base process:

[0061] Dissolve the wet PU resin in DMF solvent, prepare the PU mixed solution for the semi-finished base, use the mixed solution to impregnate and coat the non-woven fabric, and then put it into the non-woven fabric that has affinity with the solvent but not with the PU resin. in liquid. The solvent in the mixed solution is extracted to form a wet film. Continuous air bubbles are generated during the solvent extraction process, resulting in a porous film, and the semi-finished base is obtained after washing to remove DMF in the film and drying.

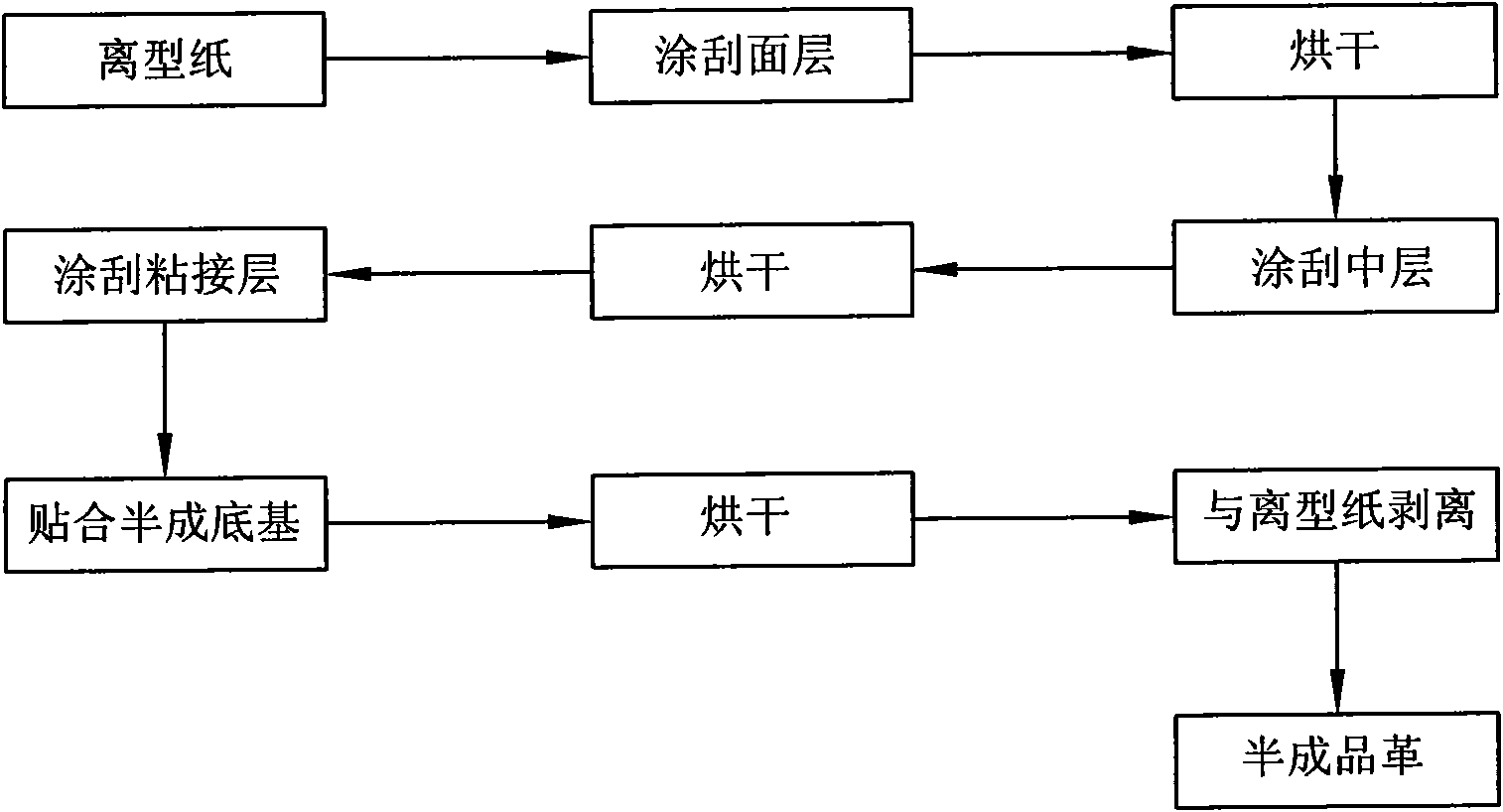

[0062] The second stage: the technological process of semi-finished leather:

[0063] Dissolve the dry-process PU resin mixture in DMF and MEK, and use a sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com