Connecting structure and construction method of precast concrete plates and beams, and building comprising same

A prefabricated concrete slab and connection structure technology, which is applied in the direction of construction and building construction, can solve problems such as damage, leakage, and failure to form a unified whole, and achieve the effect of preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

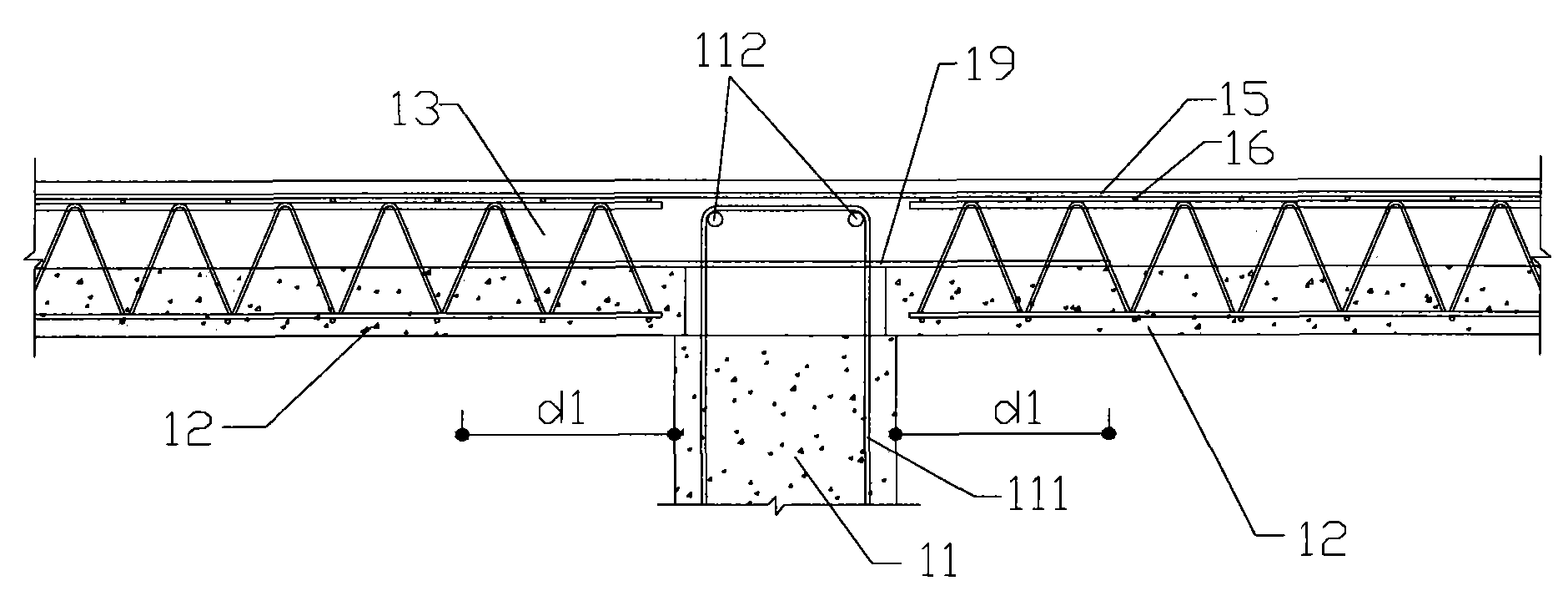

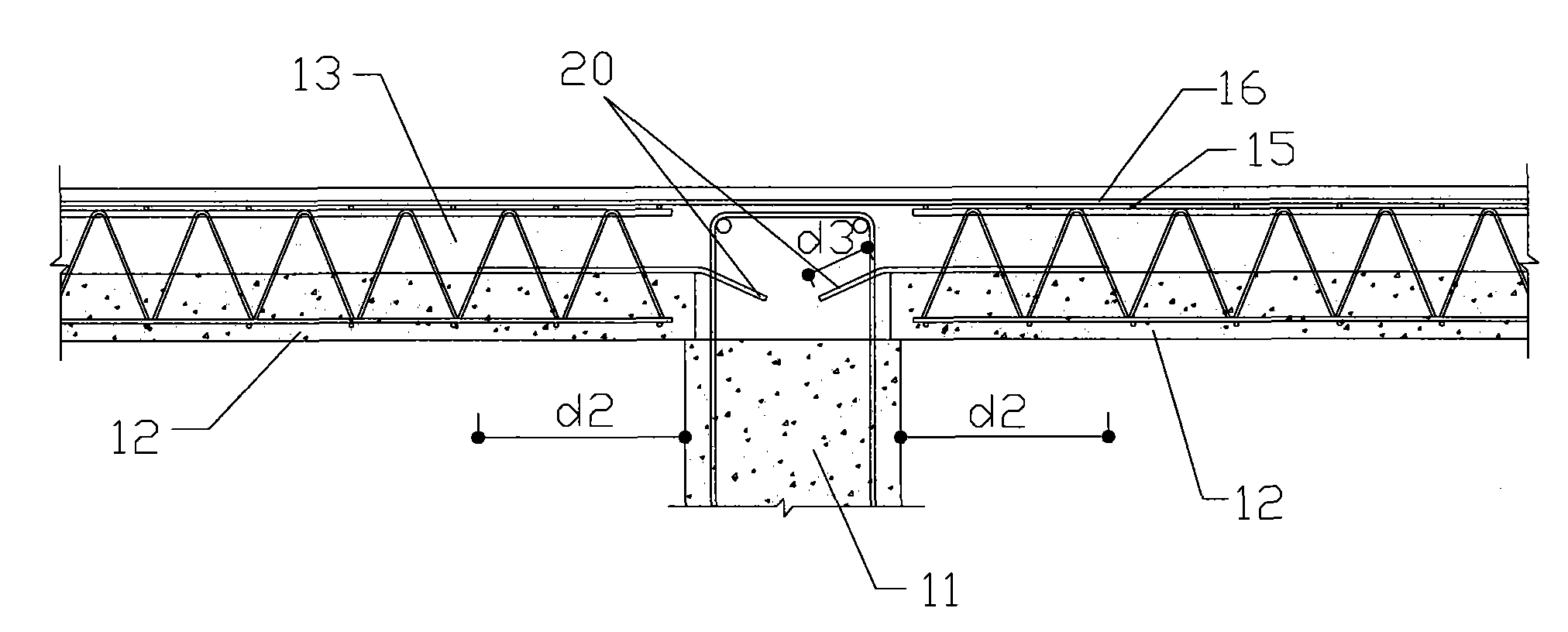

[0024] The invention provides a connection structure between a prefabricated concrete slab and a beam. The prefabricated concrete slab has a reinforced concrete structure. The ends of the two prefabricated concrete slabs are respectively overlapped on both sides of the top surface of the beam. The upper part is provided with a superimposed layer that connects the beam and two precast concrete slabs into one. Through the above-mentioned superimposed layers, the beam and the prefabricated concrete slab form a unified whole, which ensures the safety and reliability of the beam and the prefabricated concrete slab in terms of stress.

[0025] like figure 1 As shown, it is a schematic cross-sectional structure diagram of the first embodiment of the connection structure of the precast concrete slab and the beam of the present invention. In this connection structure, the ends of the two precast concrete slabs 12 are overlapped on both sides of the top surface of the beam 11 (for exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com