LNG storage tank and inner tank thereof

An inner tank and storage tank technology, applied in the field of liquefied natural gas storage container equipment, can solve problems such as affecting construction and installation, affecting the mechanical performance of LNG storage tanks, etc., and achieve the effect of low cost and reasonable application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

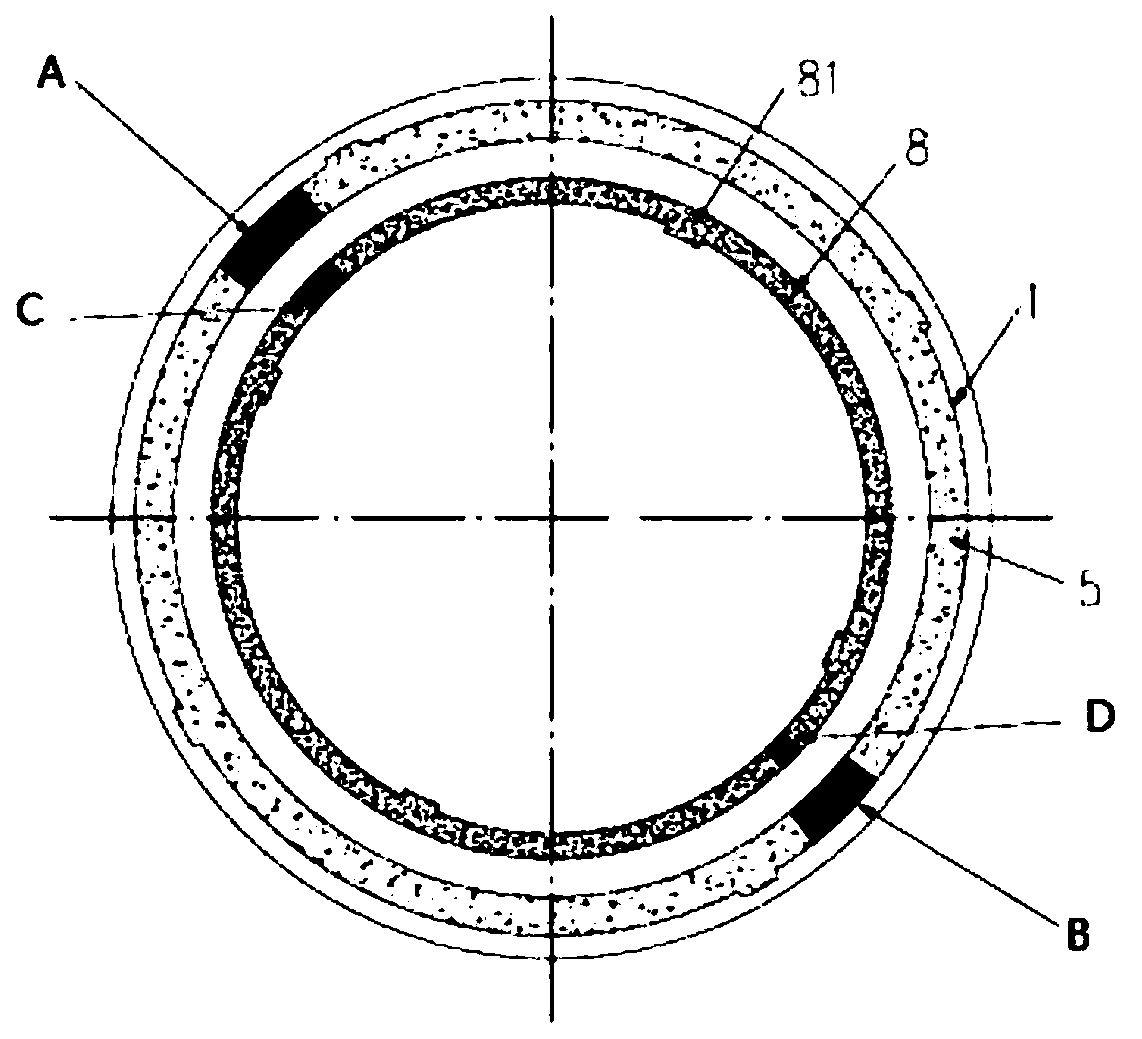

[0056] According to an embodiment of the present invention, the side of the buttress column is provided with an anchor system, and the anchor system is fixed with prestressed tendons.

[0057] Every two buttress columns arranged at 180 degrees in the circumferential direction are used to fix a group of anchor points of the prestressed tendons.

[0058] According to an embodiment of the present invention, the wall of the inner tank is provided with channels for prestressed tendons, and the two ends of the prestressed tendons are respectively fixed on the anchor system, and the two ends of each of the prestressed tendons One end of each leads out from the anchoring systems on both sides of the same buttress column, and then crosses through the prestressed tendon channel in the inner tank.

[0059] The above-mentioned prestressed tendons fixed on the buttress columns form the circumferential prestressed tendons of the inner tank.

[0060] According to an embodiment of the presen...

Embodiment

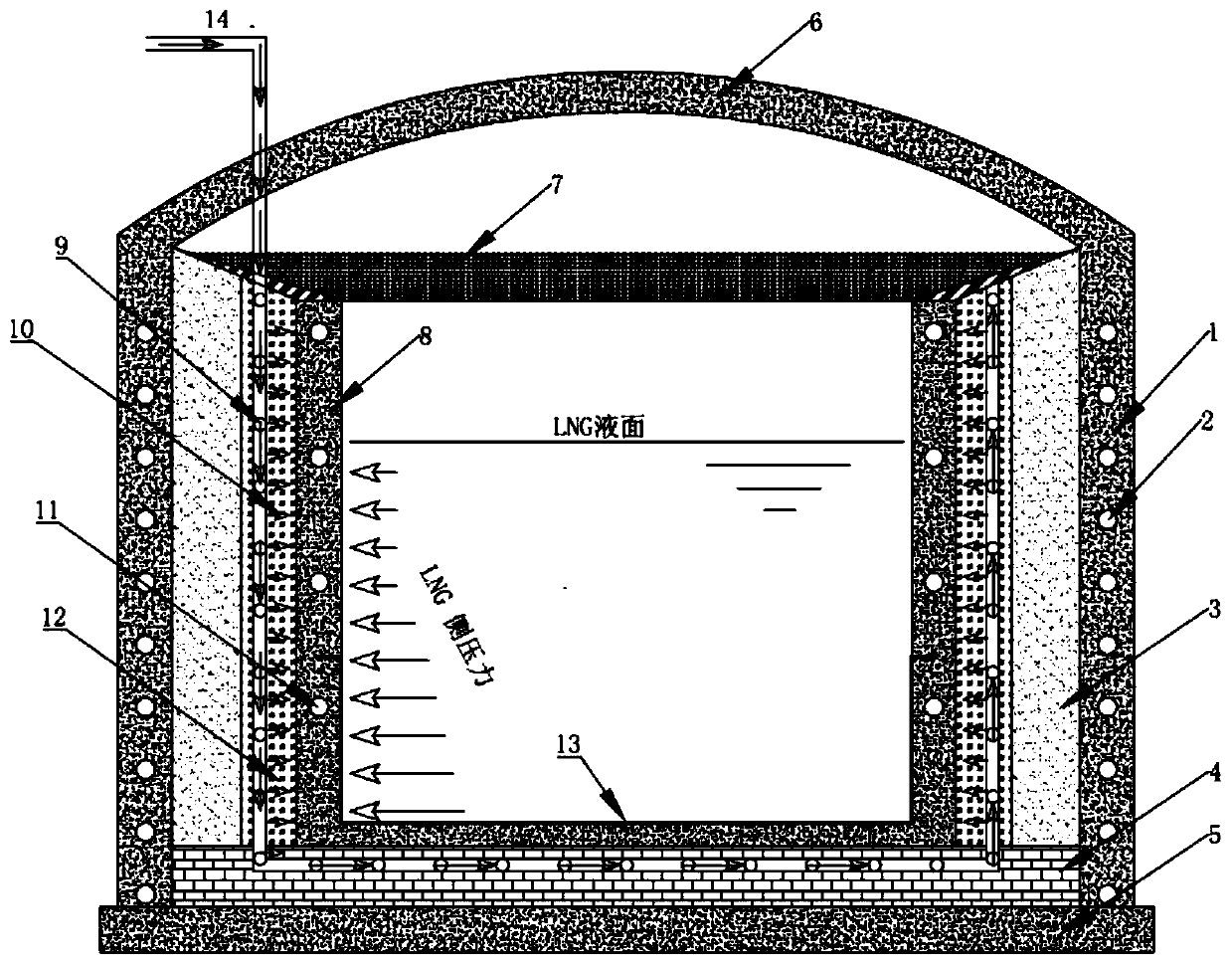

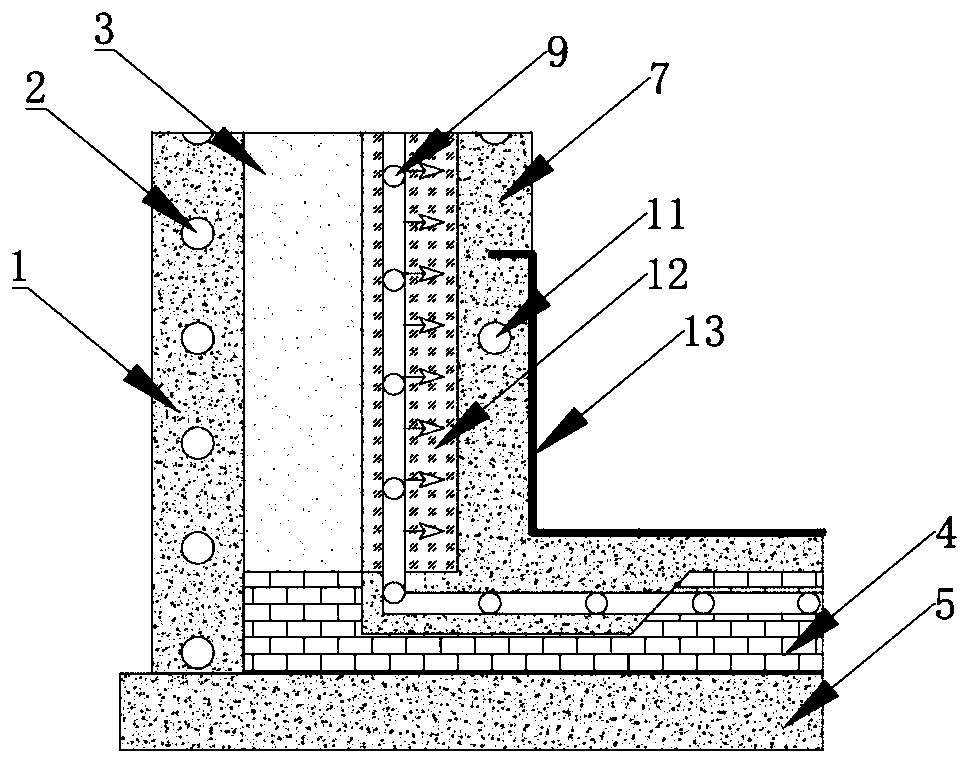

[0071] A LNG storage tank, such as Figure 1 to Figure 4 As shown, it mainly includes prestressing system, concrete outer tank 1, concrete inner tank 8 (including built-in buttress column), concrete cap 5, concrete dome 6, cold insulation system, pipe network airtight system 9, liquid bearing Pressure system 13.

[0072] The prestressing system of the above-mentioned airtight full-concrete LNG full-capacity storage tank equipment adopts 1×7 standard steel strands with a diameter of 15.7mm, including 12-25 strands and other different types.

[0073] The outer tank 1 of the above-mentioned airtight full-concrete LNG full-capacity storage tank equipment is a cylindrical prestressed reinforced concrete structure with a height-to-diameter ratio of 0.6 and a wall thickness of 0.8m. The material is C40 or C50 strength grade concrete, and the inner side is used Low temperature resistant steel material, the structure can withstand low temperature below -40°, without cold and brittle f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com