Sludge pump impeller with integrated reamer and impeller

A technology for sludge pumps and impellers, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as blockage of pump flow channels, increase suction pressure, increase negative pressure, and enhance The effect of total negative pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

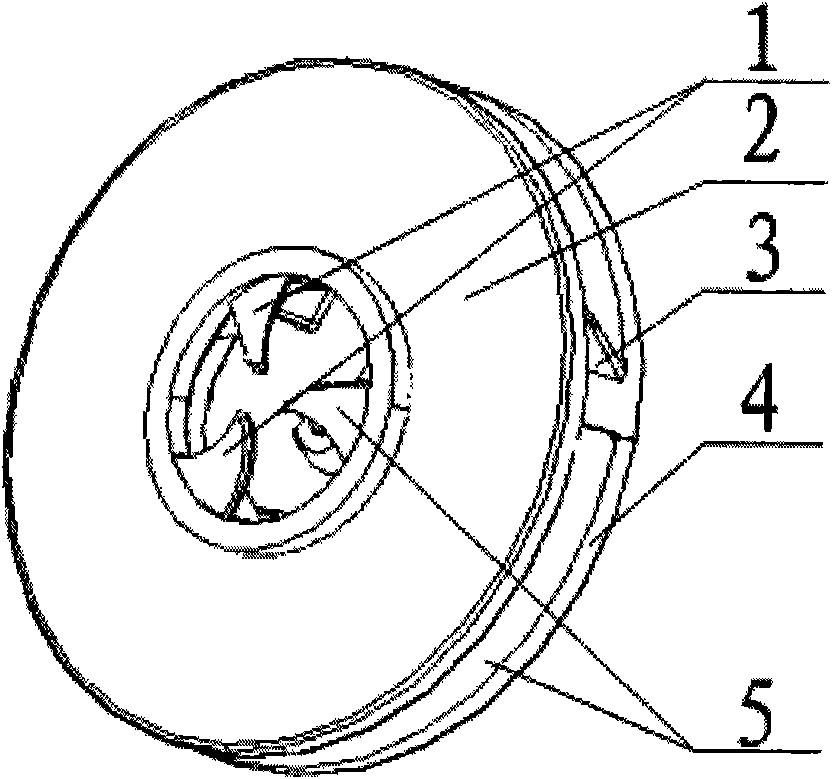

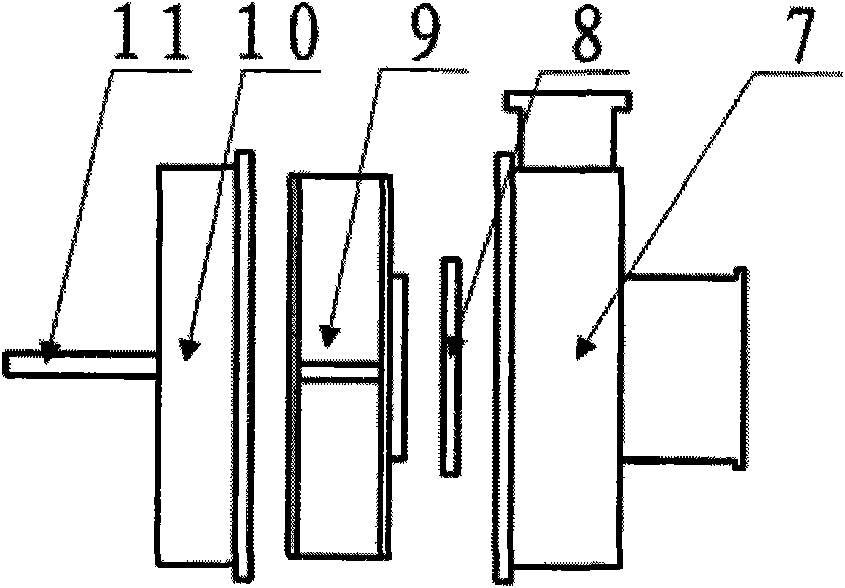

[0014] refer to figure 1 and figure 2 , the present embodiment includes the impeller body 9 fixed with the blade 3, the impeller front cover plate 2, the impeller rear cover plate 4, the shaft 11 that plays a connecting role, the bearing 8 that fixes the impeller body 9 to ensure its smooth operation, and the impeller front cover plate 2 A circular reamer frame 6 is provided at the feed inlet of the feeder, and blade-type reamers 1 that are evenly distributed are fixed inside the circular reamer frame 6. The blade of the blade-type reamer 1 is forward-rotating, and the blade is right There are blades on the side facing the direction of flow.

[0015] The tip of the vane reamer 1 points radially to the axis of the inlet channel.

[0016] When installing with the pump body, the annular reamer frame 6 used to fix the blade reamer 1 is integrated with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com